Care and maintenance, Spare parts, Main parts – Xylem IM162 R03 Dewatering Pumps Contractor Dewatering Pump User Manual

Page 5

5

WARNING

WARNING

CLEANING

If the pump has been running in very dirty water, let it

run for a while in clean water, or flush it through the

discharge connection. If clay, cement or other similar

dirt is left in the pump it may clog the impeller and seal,

preventing the pump from working.

During a long period out of operation, the pump must

be test run every other month to prevent the mechanical

seals from sticking together.

Watch out for the starting jerk, which can

be powerful.

Always lift the pump by its carrying handle

or lifting eyes, never by the motor cable or

the hose.

Care and Maintenance

INSPECTION

Regular inspection and preventive maintenance ensure

more reliable operation.

The pump should be inspected at least twice a year, more

frequently under severe operating conditions.

TIGHTENING SCREWS

During assembly or service of the pump we recommend

that the screws be tightened to approximately

4.5 - 6 ft lbs (6-8Nm).

This tightening torque ensures that the parts are correctly

fastened and that the pump will operate as intended.

NOTICE: Make sure that the oil-plug screw is not

tightened too hard.

Be sure to disconnect the power supply

before attempting inpection, as the pump

may start automatically.

LUBRICATING SCREWS

To maintain screw tightness use a little mineral oil on all

non-stainless screws (not synthetic lubricants!).

NOTICE: When using stainless steel screws on stainless

steel parts we recommend that ARAL DEGOL

GS 460 or National Chemseal THREAD-EZE

lubricants be used to prevent screws from

seizing or getting stuck.

If the motor cable on this pump is damaged

the cable may only be changed by a repair

shop authorized by the manufacturer. This is necessary as

special tools are required to change the cable.

Spare Parts

SPARE PART KITS

Spare parts for the dewatering pumps are available in

handy kits to make service and repair work easier. Each

kit contains an instruction sheet together with the

replacement parts.

WARNING

WARNING

Kit type

½ HP

1 HP

60Hz, Kit No.

60Hz, Kit No.

Impeller Kit

15K11

15K12

Diffuser Kit

15K13

15K13

Outer Seal Kit

15K14

15K14

Each Kit contains the following parts:

Impeller Kit

Impeller, Impeller screw,

Protective plug, Washer,

Assembly instruction

Diffuser Kit

Diffuser, Barrel nuts, Screws,

Washers, Assembly instruction

Outer seal Kit

Mechanical face-seal unit,

Assembly instruction

Please contact your local distributor for further details

regarding spare parts etc.

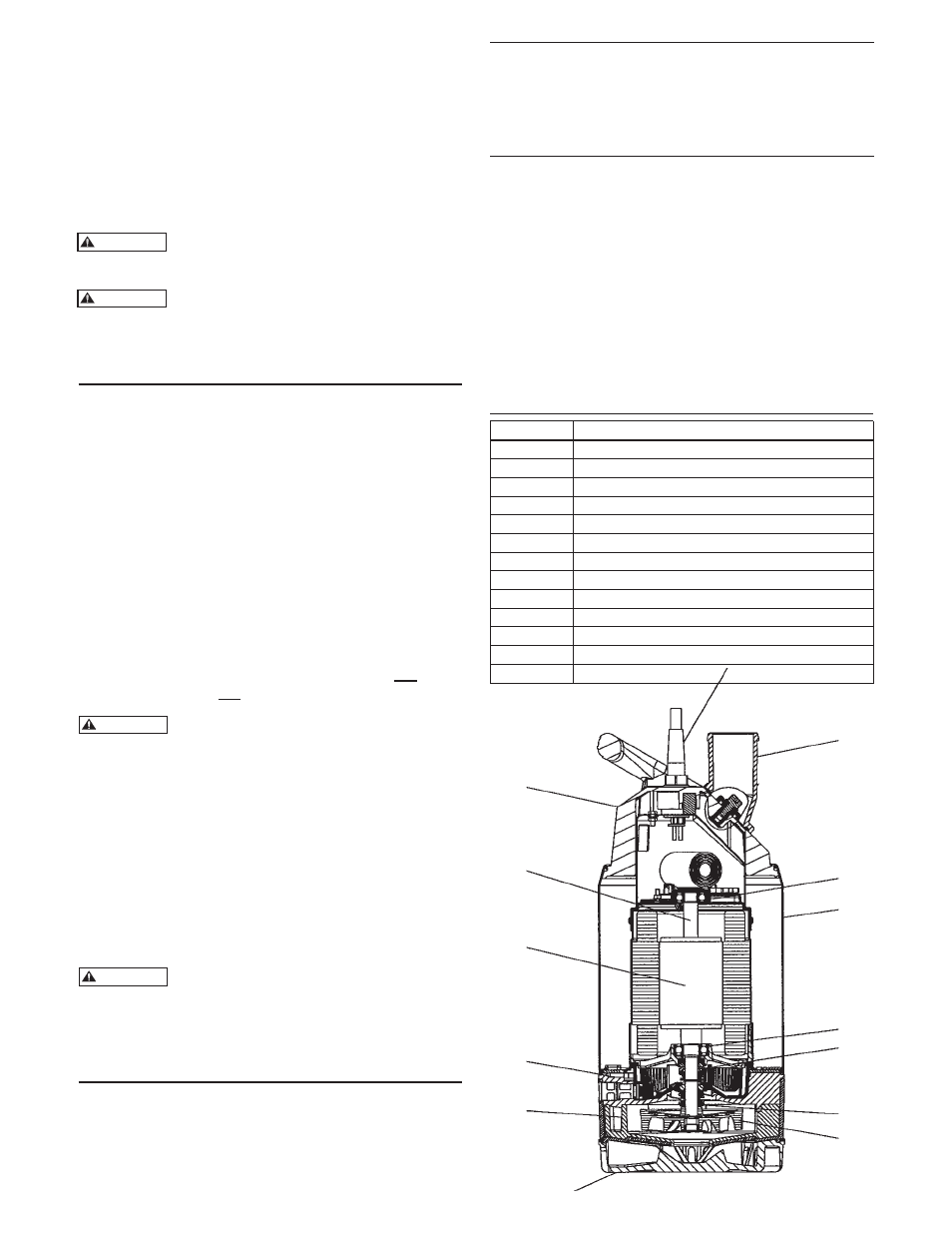

Main Parts

Item No.

Description

1 Discharge

2

Power cord

3 Handle/cover

4

Support bearing

5

Pump casing

6

Main bearing

7

Inner mechanical seal

8

Outer mechanical seal

9 Impeller

10

Suction cover

11 Strainer

12

Oil plug

13, 14

Motor

1

2

3

4

5

6

7

8

9

11

10

12

13

14