Troubleshooting – Xylem IM117 R01 5 and Larger Submersible Pump User Manual

Page 16

16

WARNING

Hazardous voltage

can shock, burn or

cause death.

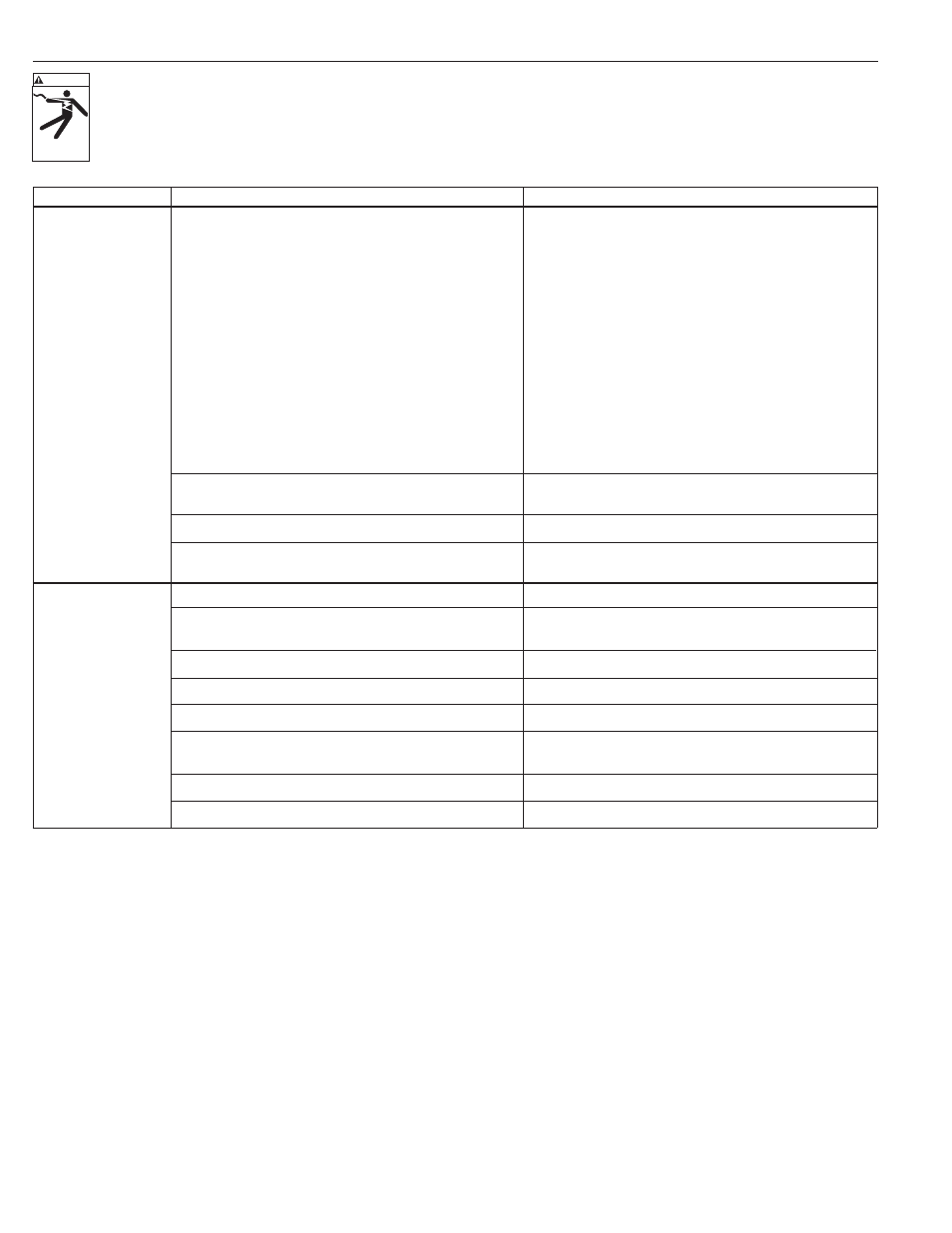

TROUBLESHOOTING

DISCONNECT AND LOCKOUT ELECTRICAL POWER BEFORE ATTEMPTING ANY SERVICE. FAILURE

TO DO SO CAN CAUSE SHOCK, BURNS OR DEATH.

Symptom

Probable Cause

Recommended Action

PUMP MOTOR

NOT RUNNING

LITTLE OR

NO LIQUID

DELIVERED

BY PUMP

1. Motor thermal protector tripped

a. Incorrect control box

b. Incorrect or faulty electrical connections

c. Faulty thermal protector

d. Low voltage

e. Ambient temperature of control box/starter

too

high

f. Pump bound by foreign matter

g. Inadequate submergence

2. Open circuit breaker or blown fuse

3. Power source inadequate for load

4. Power cable insulation damage

5. Faulty power cable splice

1. Allow motor to cool, thermal protector will

automatically reset

a – e. Have a qualified electrician inspect and

repair, as required

f. Pull pump, clean, adjust set depth as required

g. Confirm adequate unit submergence in

pumpage

2. Have a qualified electrician inspect and repair,

as required

3. Check supply or generator capacity

4 – 5. Have a qualified electrician inspect and

repair, as required

1. Faulty or incorrectly installed check valve

2. Pump air bound

3. Lift too high for pump

4. Pump bound by foreign matter

5. Pump not fully submerged

6. Well contains excessive amounts of air or gases

7. Excessive pump wear

8. Incorrect motor rotation – three phase only.

1. Inspect check valve, repair as required

2. Successively start and stop pump until flow is

delivered

3. Review unit performance, check with dealer

4. Pull pump, clean, adjust set depth as required

5. Check well recovery, lower pump if possible

6. If successive starts and stops does not remedy,

well contains excessive air or gases

7. Pull pump and repair as required

8. Reverse any two motor electrical leads

TROUBLESHOOTING