Xylem 6 71 075 004A Autocirc Instant Hot Water Pump E1 BCANRT1W 06 User Manual

Page 4

4

Note: If felt necessary, replace these existing flexible

hoses with new stainless steel braided flexible hoses

in the lengths required.

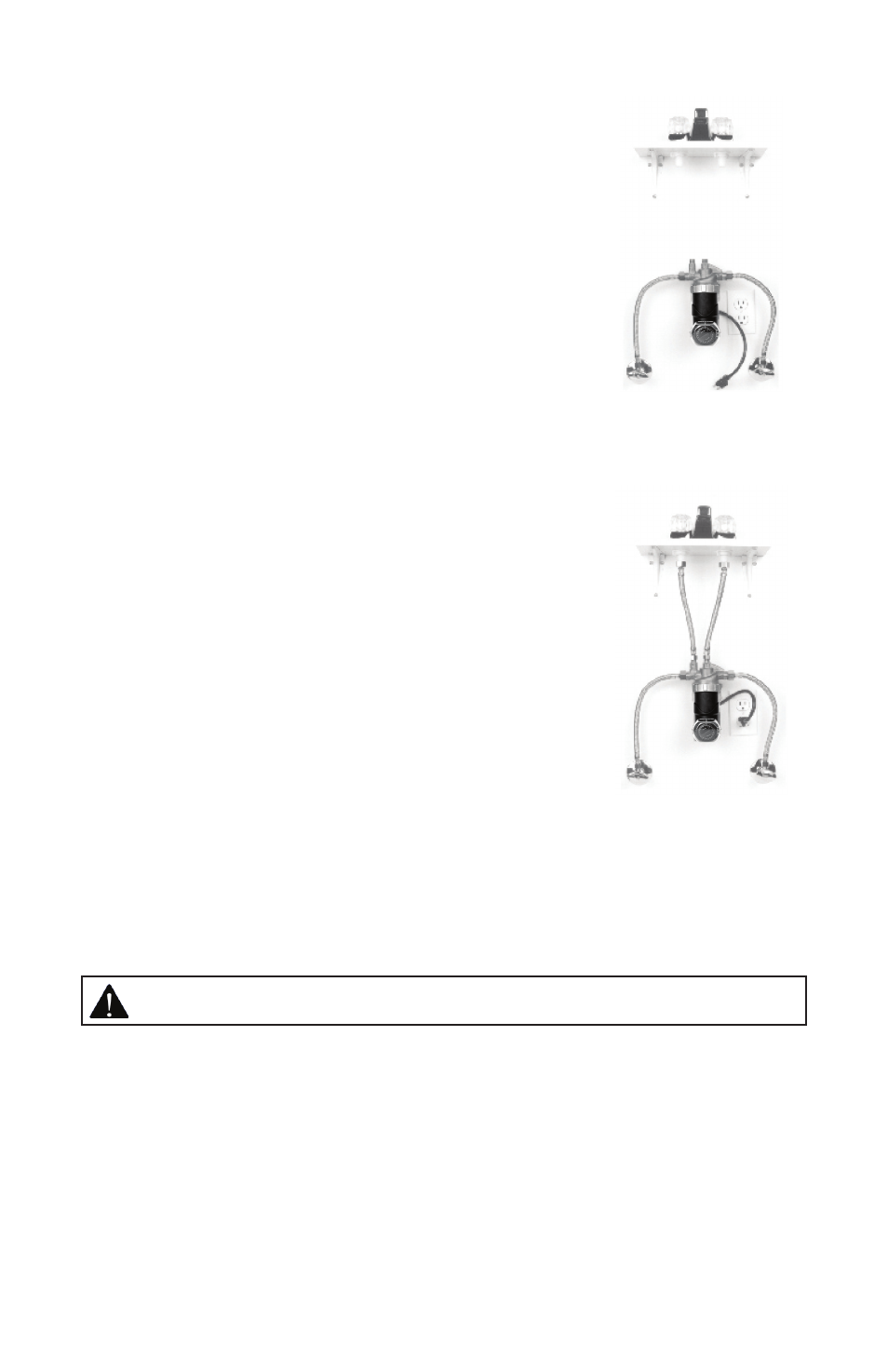

Step 4

Screw on the two existing 1/2” hose connections to

the corresponding hot and cold sides of the pump

housing (see Fig. 4). Be sure not to “kink” these

existing hose lines during bending which may

prevent adequate flow and/or cause the valves to

break.

Note: It is recommended that the rubber washers

in the hose connections be inspected to ensure

they are in reusable condition. If not, they should

be replaced.

Step 5

Screw on the 3/8” end of the purchased flexible

hoses to the 3/8” connections on the pump housing.

Screw on the 1/2” end of these same two hoses to

the underside of the hot and cold water faucets/taps

making sure to match the hot and cold sides marked

on the pump housing with the corresponding faucet/

tap. Be sure the hot side connection hose is attached

to the hot water faucet/tap and the cold water side

connection is attached to the cold water faucet/tap.

Be sure the hoses used are long enough to allow the

pump to be positioned as originally planned. ( see

Fig. 5)

Step 6

Be sure the screw ring attaching the motor to the pump housing is securely

hand tightened. Do not over tighten the screw ring. Open the faucet/tap hot

and cold riser shut off valves to insure there are no water leaks at any

connections.

Step 7

Plug the pump cord into the wall outlet and start up the pump system (see

next page).

Note: The above installation method applies to most situations where faucets/

taps are connected to the hot and cold water supply lines with braided flexible

hose/shut off valve arrangements. If the under sink arrangement is different

(i.e. the risers are hard copper or plastic), then other parts may be required for

the installation.

Figure 4

Figure 5

CAUTION: Fasten screw ring until tight to prevent leakage.