7 troubleshooting – Analytical Industries AII-2000 M Oxygen Analyzer User Manual

Page 15

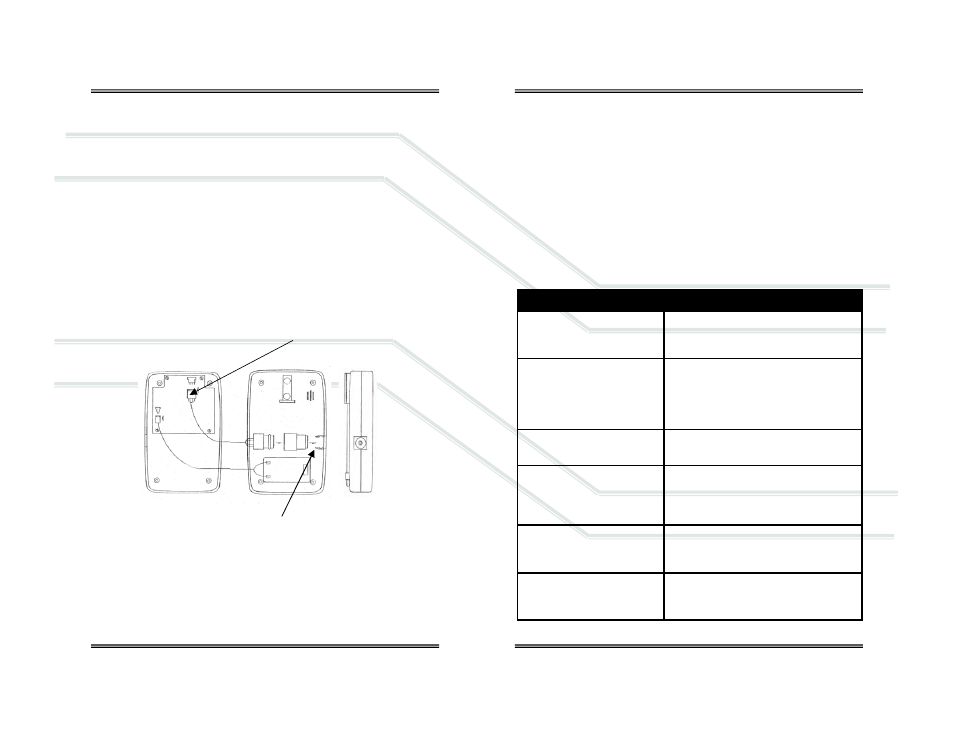

6.3.2 Procedure AII 2000HC - Integral Sensor

1. Tools required: small bladed screwdriver.

2. Place the device face down on a flat surface.

3. Remove the two (2) screws from the upper corners of the rear of the

device.

4. Move the tripod up, remove the battery compartment cover (see Battery

Replacement) and remove the two (2) screws located on either side.

5. Pull the rear section up ¼”-½”, turn it over and lay it next to the other

section.

6. Locate the white connector at the end of the four (4) wires running from

the sensor (the cylinder with the white label) to the top of the PCB.

7. With your left for finger and thumb, grasp the sides of the back end of the

white connector where it is soldered to the PCB.

8. With your right fore finger and thumb, grasp the sides of the section of

the white connector where the four (4) wires from the sensor terminate.

9. Separate the connector - hold the white connector section your left hand

while gently pulling and wiggling the white connector section with your

right hand until it unlocks.

10. The oxygen sensor inserts into an adaptor (identified by a round recess

with a cylindrical hose adapter in the center) that slides into grooves

molded into the side of the case.

11. Hold the rear section of the case down, grasp the square edges of the

adaptor, lift up (lift straight up so as not to strip the grooves molded into

the adaptor and case) and remove the adaptor and oxygen sensor as a

single component.

26

12. Once the adapter and old sensor have been removed from the case, hold

the label of the sensor, again grasp the square edges of the adaptor and

pull – to separate the old sensor from the adaptor.

13. Remove the new oxygen sensor from the plastic shipping container.

14. Install the new oxygen sensor by reversing steps 12 through 3.

15. Calibrate the device after replacing the oxygen sensor.

7 Troubleshooting

If the recommended corrective action does not resolve the problem return the

device to the factory for service.

27

Symptom

Corrective Action

Device appears to be physi-

cally damaged

Turn device ON – if it successful passes

START-UP TEST and calibrates – proceed.

No digital display when ana-

lyzer is turned ON

Install battery

Replace battery

Check battery polarity

Check and/or clean battery contacts

Battery symbol on LCD display

Replace battery and calibrate device

LCD display reads 00.0

Install sensor

Check electrical connections

Assure electrical connections are dry

No response to keypad com-

mand

Replace battery

Cannot turn device OFF

Calibration routine in process – escape or

wait until completed