Hotpoint Ariston PK 750 X-HA User Manual

Page 20

GB

20

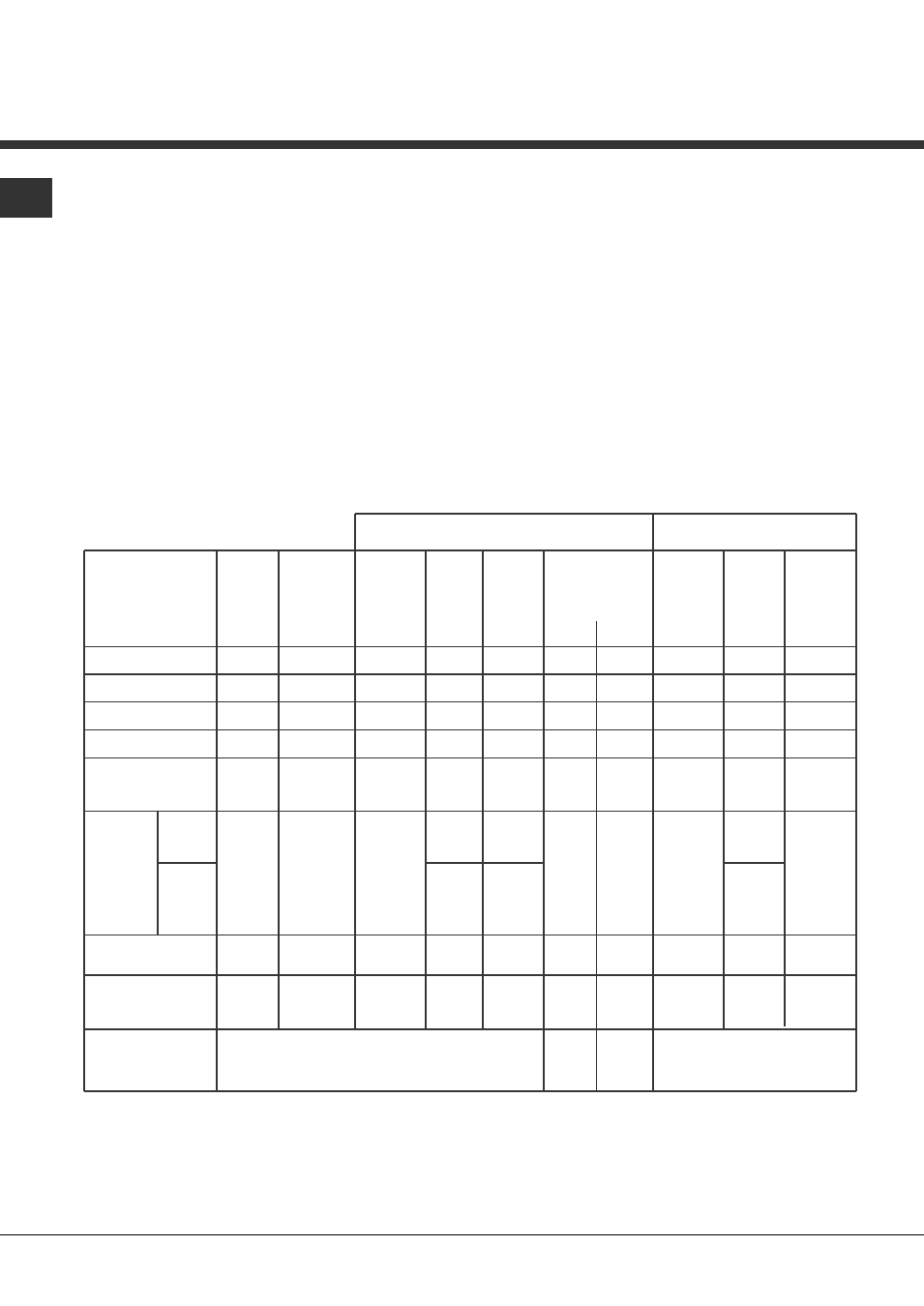

Table 1 Liquid Gas Natural Gas

Burner Diameter Thermal Thermal By-pass Nozzle Flow* Thermal Nozzle Flow*

power power 1/100 1/100 (g/h) power 1/100 (l/h)

kW kW kW

(p.c.s.*) (p.c.s.*) (p.c.s.*)

(mm) Reduced Nominal (mm) (mm) *** ** Nominal (mm)

Supply pressures

Nominal (mbar)

Minimum (mbar)

Maximum (mbar)

28-30

20

35

37

25

45

20

17

25

Fast (R)

Semi Fast (S)

Auxiliary (A)

Triple Crown (TC)

100

75

55

130

0.70

0.40

0.40

1.50

3.00

1.65

1.00

3.30

39

28

28

61

86

64

50

65x2

218

120

73

240

214

118

71

236

3.00

1.65

1.00

3.30

116

96

79

99x2

286

157

95

314

Double flame

(DCDR internal) (1)

30

0,30

0,90

27

44

65

64

0,90

72

86

Double

flame (1)

(DCDR

internal)

(DCDR

external

2 nozzle)

130

1,50

3,60

27

44

262

257

3,60

72

343

55

60x2

100x 2

Burner and nozzle specifications (for 60 cm and 65 cm versions only)

(1) For single-control DRDA (DCDR) burner only

(2) For dual-control DRDA (DCDR) burner only

*

At 15°C and 1013 mbar - dry gas

**

Propane P.C.S. = 50.37 MJ/Kg

***

Butane P.C.S. = 49.47 MJ/Kg

Natural P.C.S. = 37.78 MJ/m³

Double Flame

(DCDR Internal) (2)

Double Flame

(DCDR External)

2 nozzle (2)

30

130

0.40

1.50

0.90

3.60

27

55

44

67x2

65

262

64

257

0.90

3.60

72

100x2

86

343

5. Once the adjustment has been made, replace the seals

on the by-passes using sealing wax or a similar

substance.

6. In the event of discrete-adjustment knobs with

LED visualisation, turn the knob to the minimum

power setting them remove it and intervene on the

adjustment screw located near the tap pin.

7. Minimum setting adjustment of the DRDA (DCDR)

burner with discrete adjustment and LED

visualisation:

•

To adjust the outer ring, turn the knob anti-

clockwise to the minimum power position.

•

To adjust the minimum power setting of the

inner ring, turn the knob clockwise to the minimum

power position.

•

Remove the knob and intervene on the

adjustment screw located near the tap pin.

! If the appliance is connected to liquid gas, the regulation

screw must be fastened as tightly as possible.

! Once this procedure is finished, replace the old rating

sticker with one indicating the new type of gas used.

Stickers are available from any of our Service Centres.

! Should the gas pressure used be different (or vary

slightly) from the recommended pressure, a suitable

pressure regulator must be fitted to the inlet pipe (in order

to comply with current national regulations).