3B Scientific Friction Measuring Apparatus User Manual

Page 2

2

3. Technical data

Friction track

U-shaped track:

600 x 80 x 20 mm

3

Protractor:

0° – 60°

Sliding friction surface

Material:

PVC, smooth on one

side and coarse on the

other side

Length:

850 mm

Friction body A

Dimensions:

79 x 38 x 73 mm

3

Material: PVC

Surface: Uncoated

Surface area ratio:

2:1

Weight:

325 g approx.

Fastening rings:

2

Friction body B

Dimensions:

73 x 20 x 47 mm

3

Material: PVC

Surface:

Coated with velour pa-

per

Weight:

100 g approx.

Additional weights

Design:

To fit friction body B

Weight:

100 g

Sliders

Design:

To fit friction body B

Material:

Aluminium

Surface:

Rubber-coated (No. 1),

Teflon-coated (No. 2),

Uncoated (No. 3)

Dimensions:

55 x 55 x 15 mm

3

Friction body C

Dimensions:

75 x 31 x105 mm

3

Surface:

Coated with velour pa-

per

Weight:

325 g

Securing rings:

2

Castors:

2, ball-bearings

Dynamometer

Measuring range:

2 N, tension and com-

pression

4. Set-up

•

Secure the dynamometer by means of the

clamp.

•

Attach a stopper for the friction body to the

U-shaped track (the stopper prevents any

sudden recoil of the friction body that might

arise as the sliding friction surface is pushed

back.)

5. Measurements conducted on a horizontal

friction plane

•

Align the friction track so that the pointer on

the protractor is in the zero position.

•

Insert the sliding friction surface into the

friction track either with its smooth or coarse

facing down. Then place a friction body onto

the sliding friction surface. (See Fig. 1 and

Fig. 2.)

5.1 Static friction

•

Pull the sliding friction surface, making sure

it is displaced with a uniform motion.

•

Read the maximum value from the dyna-

mometer while the friction body is still being

dragged along with the sliding friction sur-

face.

•

Perform this measurement on several occa-

sions and calculate the average.

This value represents a measure of the static

frictional force.

5.2 Sliding friction

•

Conduct measurements as described under

5.1. However, take the reading on the dy-

namometer as soon as the friction body has

stopped moving along with the sliding fric-

tion surface.

•

Perform this measurement on several occa-

sions and calculate the average.

This value represents a measure of the sliding

frictional force.

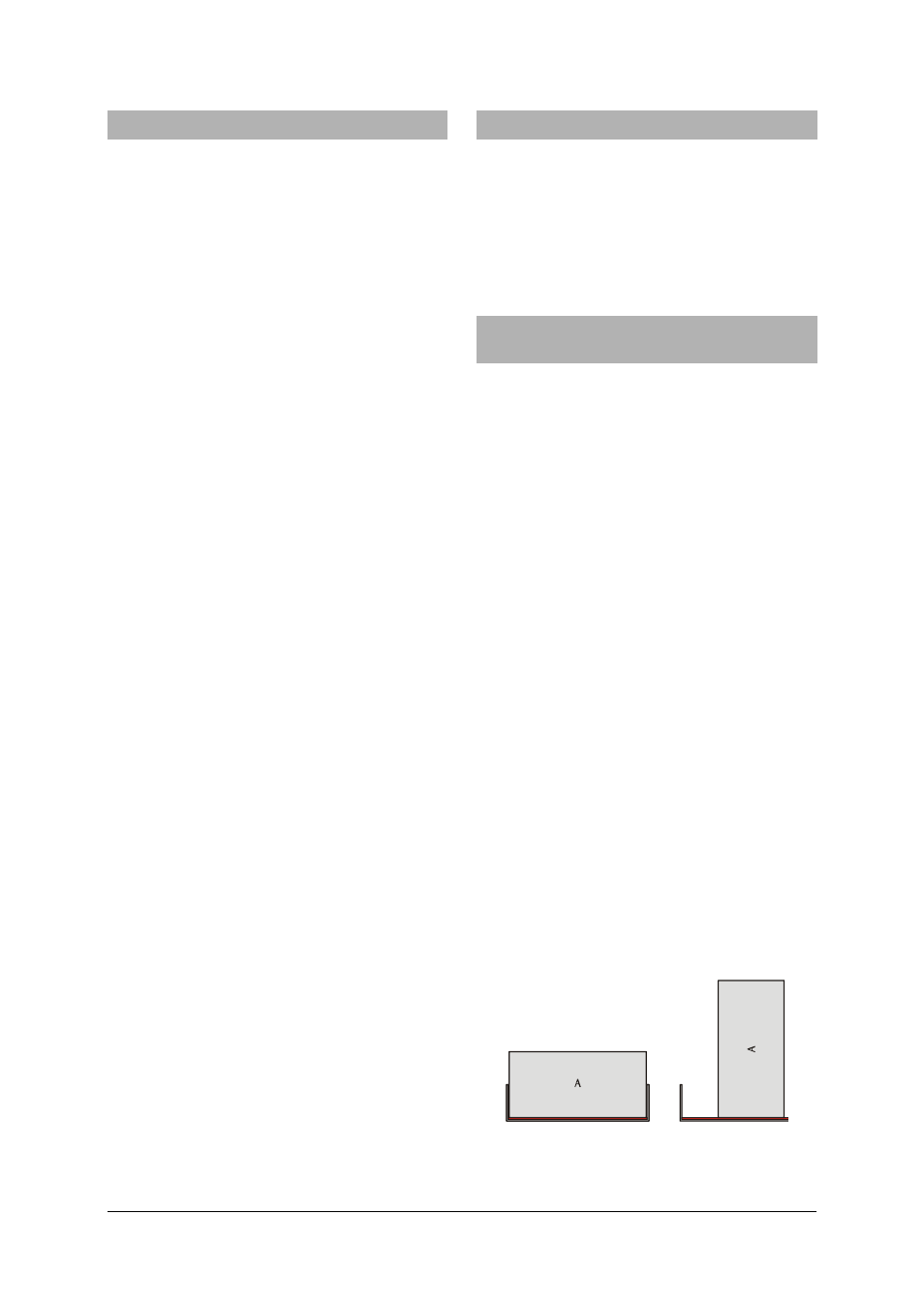

Fig. 1: Investigation of static and sliding friction with

friction body A with two different contact areas.