3B Scientific Steam Engine G User Manual

Page 2

5

•

Only put the steam engine into operation if all of the

components are in perfect condition and their func-

tionality is assured. Special attention must be made

to ensure that there are no cracks or any other dam-

age to the glass boiler

bq

.

•

Only use distilled water that has been demineralised

as per VDE 0510. If conventional tap water is used the

associated deposits that form on the safety-relevant

components mean that functionality can no longer

be guaranteed.

•

Carefully pour alcohol into the burner

bt

. Make sure

that nothing spills.

•

Never pour in alcohol while the wick is still glowing or

if there is any other open flame in the immediate

proximity.

•

Seal the bottle of alcohol immediately after use.

•

Keep away from the open flame. Be careful! Only ex-

tinguish the burner flame by means of the attached

cover. Do not blow on the flame in the proximity of

the boiler, as any sudden temperature change could

cause the boiler to crack.

•

The boiler may not be heated unless it is filled with

water. For that reason it is important to extinguish

the lamp’s flame before it boils dry.

•

Do not touch any components steam carrying, par-

ticularly the boiler

bq

, hoses

1

,

2

,

3

,

bn

, steam

exhaust pipe

br

and support frame

bm

. Do not

touch the spirit burner

bt

during or after operating

the steam engine either. Risk of burns!

•

Let the steam engine cool before storing.

2. Description, technical data

The oscillating steam engine has been designed for use

in a training and educational environment. In order that

individual operations and dynamic processes should be

observable, particular emphasis has been placed on trans-

parent construction. For that reason the main cylinder

8

and boiler

bq

are made of heat-resistant special glass

and the flywheel

5

is made of acrylic. The hardened

crankshaft

6

and the connecting rod

7

are ball-bear-

ing mounted. The graphite piston

9

runs dry in the

operating cylinder – i.e. without any added lubricant. For

that reason the steam engine runs very quietly and safe-

ly for long periods, providing a mechanical power out-

put of approx. 1 W. The safety valve

bo

is located in the

boiler cap

bp

. It opens as soon as the boiler pressure

exceeds 1.0 bar. In addition, the machine is also equipped

with a second, independent excess pressure safety mech-

anism. Up to a pressure of approx. 1.5 bars the steam is

forced into the ducts of the support frame

bm

and dis-

charged via the condensation hose

1

. When the pres-

sure exceeds 1.5 bars the cylinder flank

bl

is forced away

from the frame because the tension in the spring

4

is

overcome so that the steam can flow unimpeded out of

the steam inlet hole in the frame.

Piston diameter:

19 mm

Piston stroke:

10 mm

Boiler diameter:

50 mm

Boiler volume:

50 ml

Operating time per filling:

approx. 20-25 mins

Speed:

800 rpm

Mech. Power output:

approx. 1 W

Max. operating pressure:

0.5 bars

Trigger pressure

of the safety valve:

1.0 bars

Minimum boiler

bursting pressure test:

2.0 bars

3. How the apparatus works

Unlike a slide-valve steam-engine, an oscillating steam

engine has a cylinder that rotates on a central shaft caus-

ing steam inlet and outlet ducts to open and close. Water

in the boiler begins to boil, and thus steam is generated.

The steam flows via the steam inlet hose

bn

into the

frame then through the steam inlet hole. As soon the

opening of the cylinder is fed with fresh steam, steam

flows into the cylinder and displaces the piston (Fig. 1, a).

When the piston reaches its lowest point, the steam ducts

are closed. This slack point is passed thanks to the inertia

of a flywheel (Fig 1, b). In the next phase, the piston moves

back, opens the steam outlet and pushes out the steam

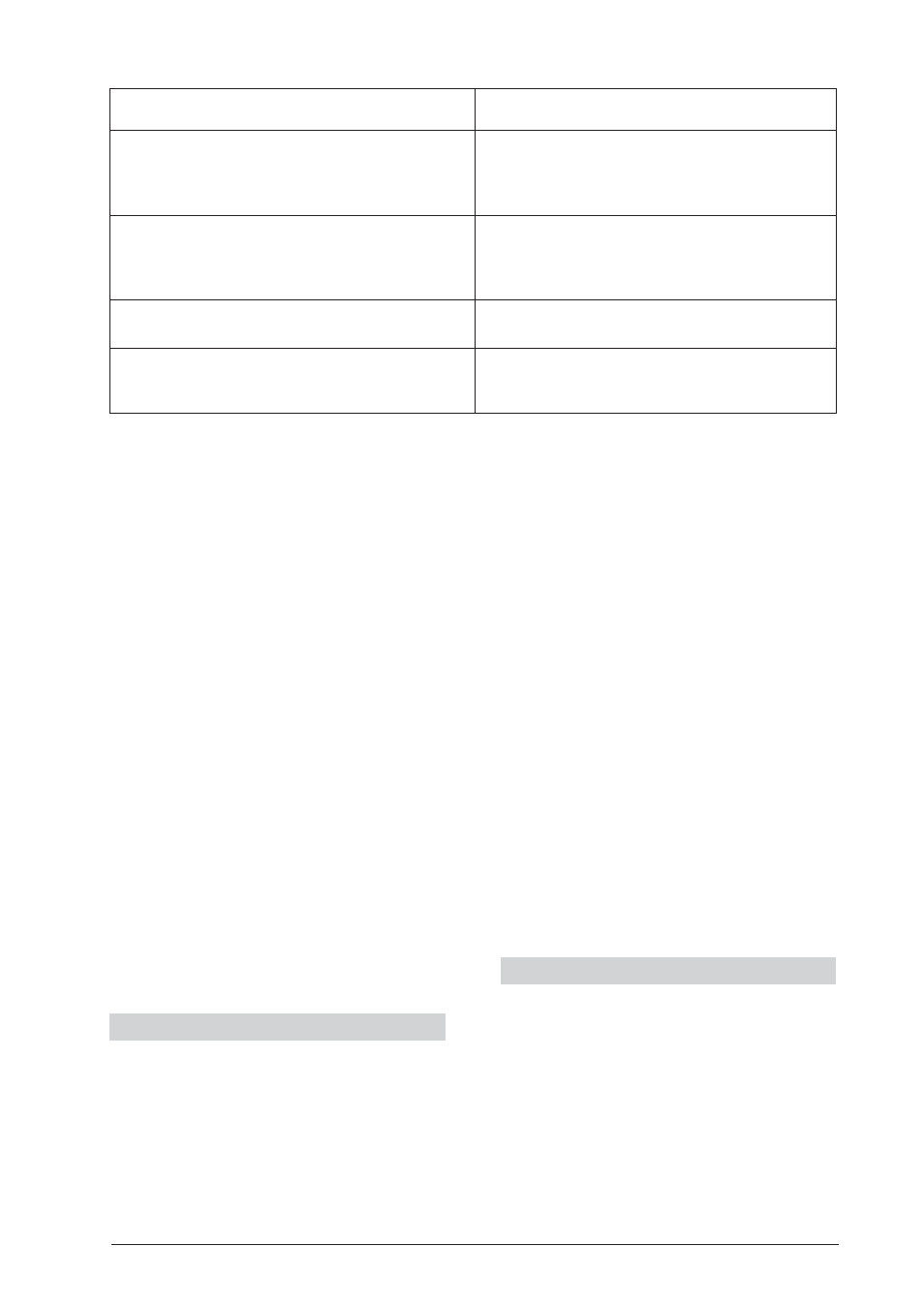

General safety standards applicable to steam engines

Specific conformance of steam engine U10055

5. An adjustable spring-operated safety valve made of

non-rusting material with a safety threshold of no

more than 3.0 bars (double the operating pressure)

must be provided.

5. This unit is equipped with an adjustable spring-ope-

rated safety valve made of non-rusting material with

a safety threshold of 1.0 bar (double the operating

pressure)

6. The bursting pressure of the boiler should be no less

than 3-times the operating pressure.

6. The boiler’s bursting pressure is at least 1.5 bars (at

least three times the operating pressure). Each boiler

is checked for safety and leaks by means of a burst

pressure test (2 bars+).

7. The water level must be visible, if possible, with the

aid of an inspection window.

7. The water level is visible at all times because of the glass

boiler.

8. An easy to understand instruction sheet is required

plus a label with the name or logo of the manufactu-

rer.

8. An instruction sheet is supplied with each apparatus.

An appropriate silk-screen printed label is located on

the base plate.