3B Scientific Optical Precision Bench D, 500 mm User Manual

Page 2

4

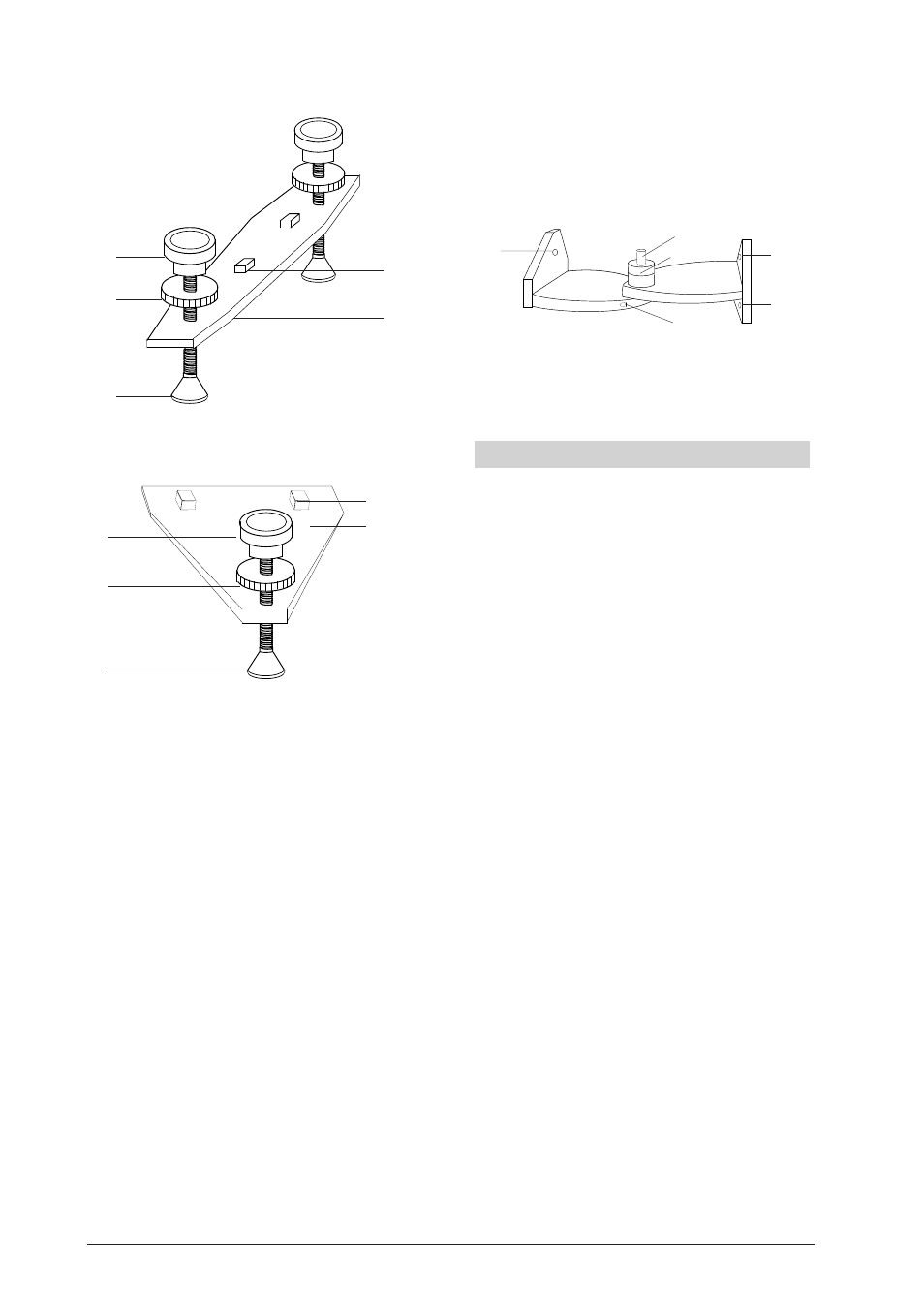

Fig. 2.1 Rail supports

Fig. 2.2 Single-point support

1

Adjustment screw to adjust the height

2

Grub-screw to secure the height

3

Stand base

4

Rail support

5

Square-socket screw to fasten the rail foot into the groove

1.3 Swivel joint

The swivel joint consists of black anodised aluminium

and can be swivelled around an angle of 90° in both

directions. A protractor has been included to set the

angle. In the rotational axis there is a sleeve to mount

optical components.

Rotational angle:

± 90°

Protractor:

±180°

Scale division:

1°

Sleeve height:

60 mm

Span width for shaft:

10 mm up to 14 mm

Figure 3

1

Drilled screw holes for fastening to the optical bench

2

Mount for protractor and sleeve

2. Operation

2.1 Assembly of the rail supports

•

Insert the square-socket screws into the guide

groove under the profile rail and fasten by tight-

ening them.

•

Adjust the height using the adjustment screw.

•

Use the grub-screw to secure the settings.

2.2 Assembly of the swivel joint

•

Take off the front plate by loosening the three fas-

tening screws.

•

Place the swivel joint on the rail and secure it by

tightening the three screws.

•

Connect the swivel joint to the second rail in like

fashion.

2.3 Recommended rider and assembly aids

•

For the assembly of elements in the optical axis:

Optical rider (U10310 to U10312 and U10315 to

U10317)

Double rider (U10340 to U10342)

•

To tilt element out of the optical axis:

Tilting rider (U10330)

•

To slide elements perpendicular to the optical

bench axis: sliding rider (U10320)

•

To position elements adjacent to the optical axis:

Extension arm (U10331)

2

4

5

1

3

1

2

3

4

5

1

2

1

1

1

2

3B Scientific GmbH • Rudorffweg 8 • 21031 Hamburg • Deutschland • www.3bscientific.com • Technical amendments are possible