Is it an art, Or is it science – Dynatek Labs Mock Vessels User Manual

Page 2

Θ

B

i

A

i

A

f

B

f

O

Ci

r

f

r

i

Dynatek Labs: The Performance Leader for Mock Vessels

With a history of nearly 30 years of research and innovation behind us, Dynatek Labs produces the

most precise mock silicone vessels in the world. Dynatek pioneered the fabrication of mock vessels for

use in testing stents, stent grafts and some kinds of heart valves. Honed over decades, accuracy and

precision are the hallmarks of our proprietary mock vessel fabrication process, and today we are the

first choice for mock vessels by virtually every stent manufacturing company in the world.

High precision mock vessels made to exacting standards

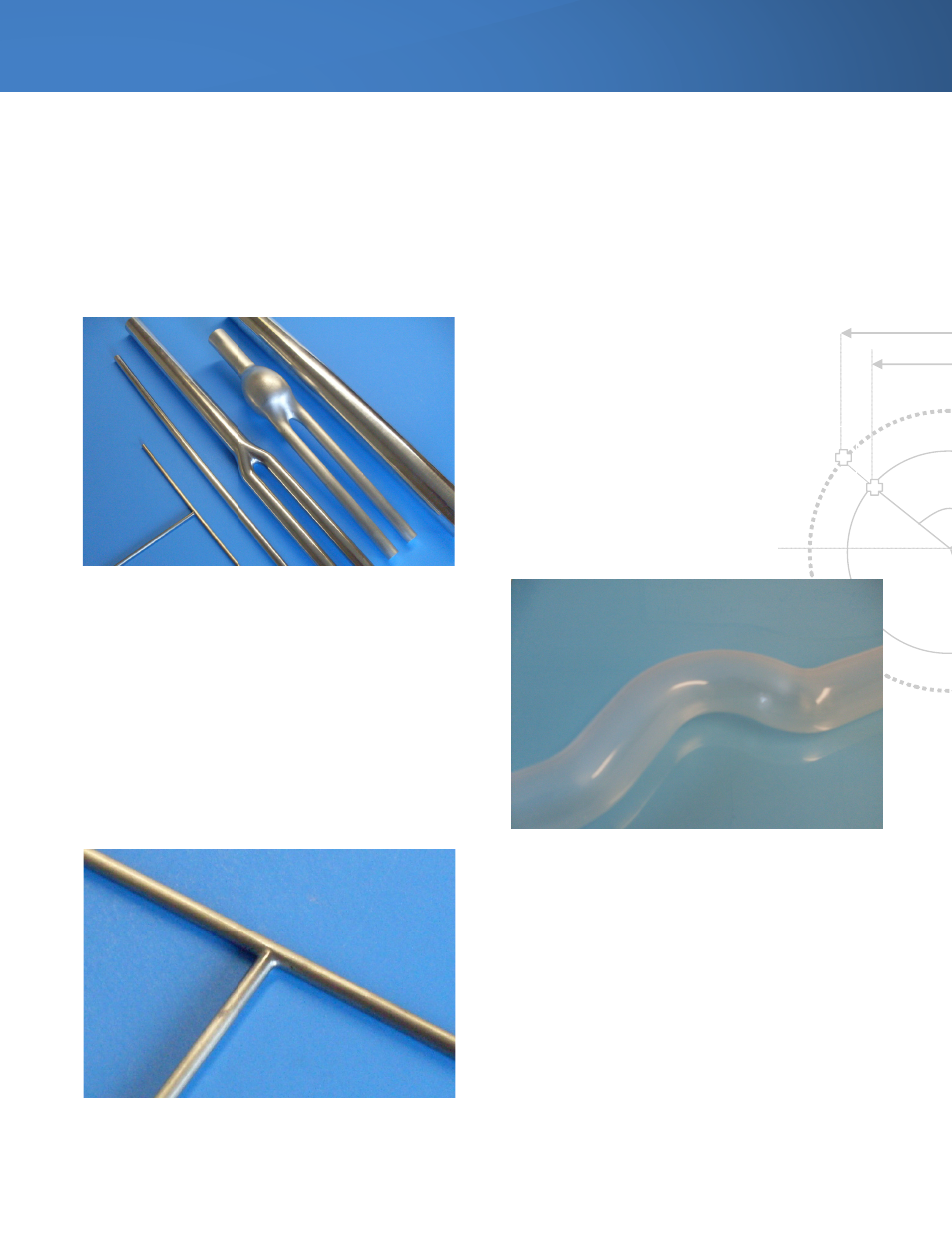

What’s in a mandrel?

A mandrel is usually a stainless steel or aluminum rod accurately

shaped to the customer’s vessel specifications and used as a mold

for fabricating the mock vessel. A mock vessel can meet the required

specifications only if the mandrel from which it is made captures

the specifications accurately. Dynatek’s mandrels are machined and

finished to extremely close tolerances so that mock vessels from every

mandrel meet the requirements exactly.

Is it an art?

Yes, it is. Silicone is a tricky material to work with. Dynatek has nearly

three decades of research experience working with silicone and we

know, for example, exactly how much shrinkage to expect when the

mock vessel is removed from its mandrel. It is this kind of knowledge

that makes Dynatek’s mock vessels the most accurate and consistently

precise in the world.

Or is it science?

Yes, it is. The photo on the left is a close-up of a T-bifurcated mandrel.

In fact, it is a CNC-machined two-piece mandrel with the joint made

to such close tolerances that the seam is invisible to the naked eye.

Advantage? A bifurcated mock vessel with an ultra-smooth, bubble-

free interior and naturally curved surfaces near the joint, just like a real

vessel in vivo.