Problem possible cause solution – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1418 User Manual

Page 13

PNEG 1418 Sales Information Package

13

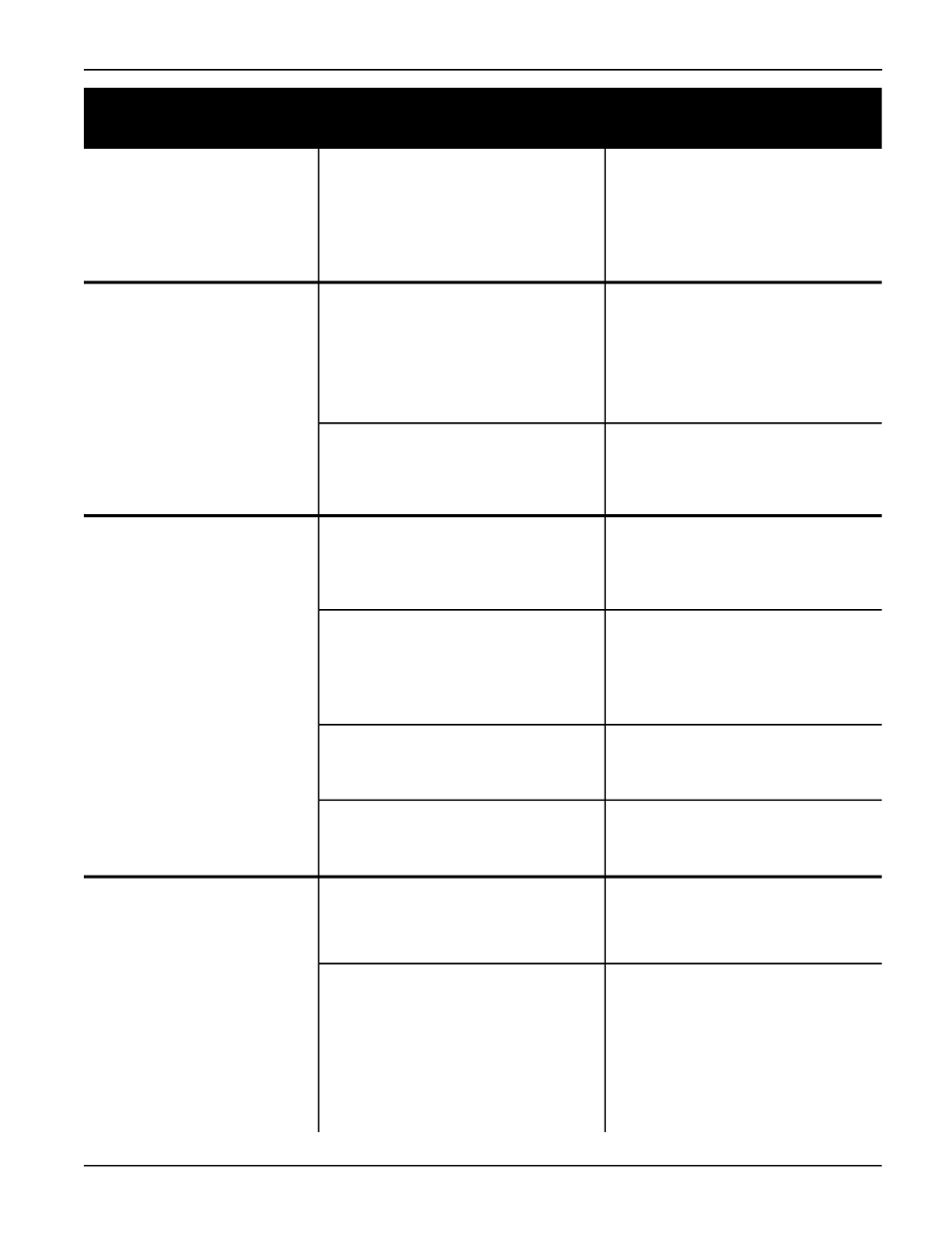

4. DRIVELINE SHEAR BOLT

SHEARS FREQUENTLY.

A1. Reduce the flow rate of grain into

the ground hopper.

A. Grain may be flowing too quickly

into the ground hopper.

B. The discharge of grain from the

main auger may be restricted.

B1. Inspect auger intake and dis

charge areas for damage.

Problem

Possible Cause

Solution

1. THE AUGER IS

VIBRATING.

A. Damage can occur to the auger

flighting, causing noise.

Damage usually is caused from

foreign materia l be ing run

through the auger.

A1. It may be necessary to remove

the flighting for inspection.

2. CAPACITY IS TOO LOW.

A. There may not be enough grain

reaching the auger.

A1. Make sure the intake has not

bridged over, restricting flow.

The flighting at the intake should

be covered with grain for maxi

mum capacity.

B. The auger is moving too slowly.

B1. Check the auger speed. Low

capacity will result from speeds

slower than recommended.

3. THE AUGER PLUGS.

A. The auger may be "jamming"

because too much grain is

reaching the auger.

B. The grain may be wet.

B1. If wet grain or other hardto

move material is being augered,

reduce the amount of grain

being fed into the swingaway

hopper.

C. The auger may be jammed with

foreign material.

C1. Remove any foreign material

in the auger.

D. The discharge end may be

plugged.

D1. Unplug any plugs at the dis

charge end of the auger.

A1. Decrease the amount of grain the

auger is gathering.