Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1759 User Manual

Quick start guide, Series ii sweep, Gsi-bins

NOTICE: PRIOR TO OPERATION, READ THE OWNERS MANUAL FOR IMPORTANT SAFETY INSTRUCTIONS AND FULL EQUIPMENT DETAILS

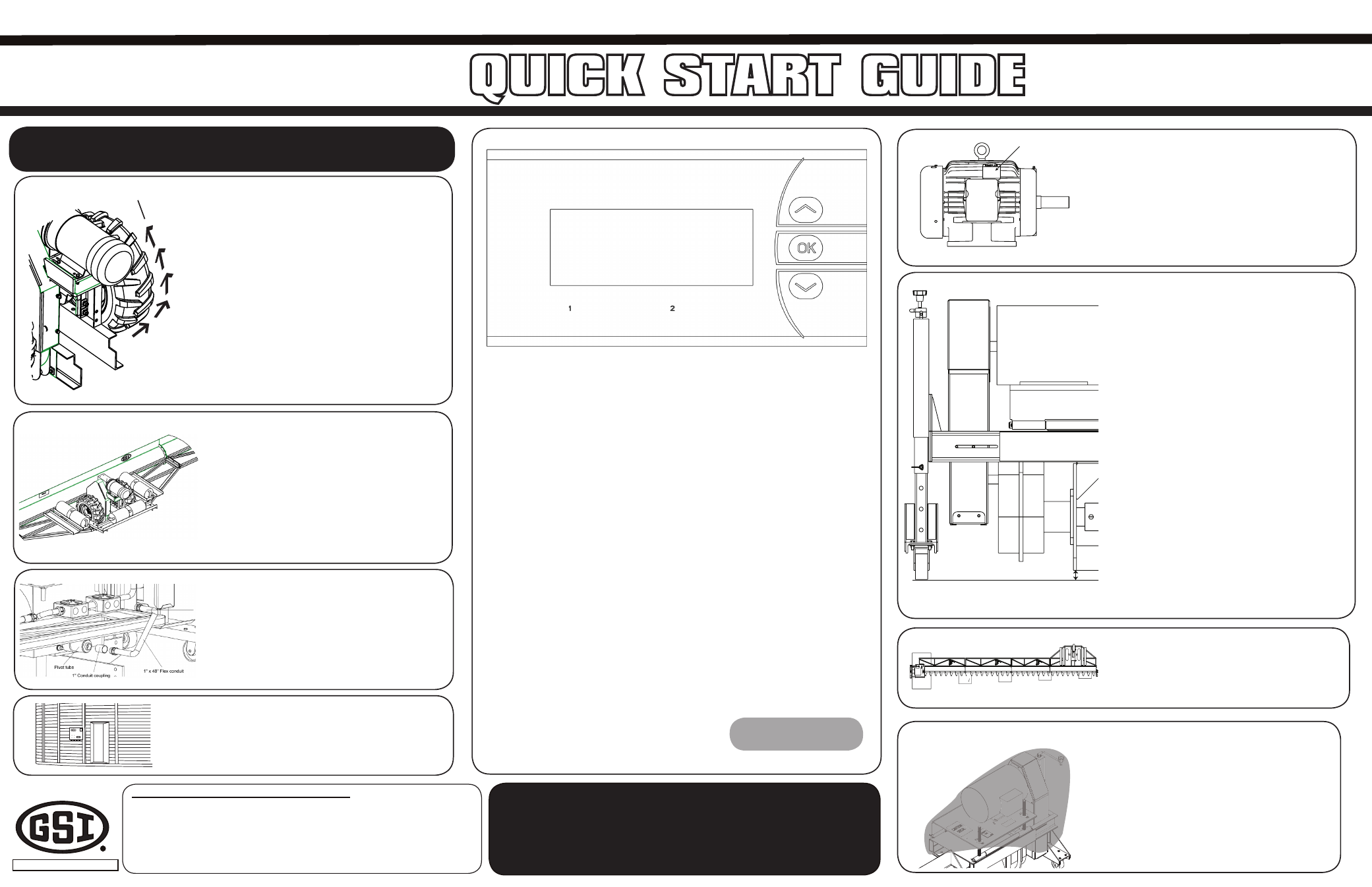

SERIES II SWEEP

QUICK START GUIDE

888-GSI-BINS

PERSONAL EQUIPMENT RECORD

Auger Motor FLA:

90% FLA Auger Motor:

Tractor Motor FLA:

110% NLA Auger Motor:

Hys 1:

www.grainsystems.com

DANGER: NEVER ENTER THE BIN UNLESS ALL

POWER IS DISCONNECTED AND LOCKED OUT.

Initial Use Check List:

• Check tire tread installation direction

(tread will be installed backwards to

normal tractor tire installation. Rims

should be installed dished for maxi-

mum clearance betweent the tire and

the side frame trussing).

• Check gear boxes for oil and vent plug

installation (See manual for types and

volumes required).

• Check tractor drive chain tension and

alignment (reinstall all guards after

checking).

• Check main drive belt’s tension and

alignment, then reinstall all guards.

Position weights (2 on each side of drive

wheels, in line, on closest channel to tires

and 2 on first cross channel behind tractor

drive on weight extension kit).

NOTE: Weight extension kit should be

removed prior to filling the bin or the back

cross channel should be removed and the

support channels shortened to not extend

beyond the first cross channel.

Check electrical conduit is installed as

shown in the manual (directly behind the

auger back shield and fully supported

by the frame trussing). The connection

from the rigid conduit to the motors must

be made utilizing flexible conduit. Check

to ensure the conduit is routed and pro-

tected from all moving components.

Control panel should be mounted in a po-

sition to allow the operator to observe the

sweep through the side entry door, moni-

tor the amp meter, and comfortably access

the foot safety switch.

Program Amp Meter:

Press OK to RELU.

Press

↑ to DISP.

Press OK to REL1.

Press

↑ to SET.

Press OK to SETP.

Press

↑ to 90% of FLA-Auger Motor.

Press OK to ACT1.

Press

↑ to INCR.

Press OK to HYS1.

HYS1 = 90% of FLA-Auger Motor - 110% NLA-Auger Motor

Press

↑ to this value.

Press OK to ERR1.

Press

↑ to DEAC.

Press OK to ON.DE.

Press

↑ to 0.

Press OK to OF.DE.

Press

↑ to 20.

Press OK to REL2.

Press

↑ to OFF.

Press OK to E.PAS.

Press

↑ to NO.

Press OK to “----“.

Example: Full load amps = 21 amps

90% FLA Auger Motor = 18 amps

110% NLA Auger Motor = 12 amps

“HYS 1” = 6 amps (18 amps -12 amps)

Record your specific values

in the personal equipment

record box below.

Check motor “Full Load Amperage” and

set the overloads in control panel slightly

higher than the Full Load Amp (FLA) value

listed on the motor name plate. Record

values in the PERSONAL EQUIPMENT

RECORD at the bottom of the page.

1/2”-1”

Adjust sweep:

1. Raise all jacks up so they are not touch-

ing the floor.

2. Starting at the center of the bin, bring

the center drive support jack down un-

til it contacts the concrete, then give the

handle one more full turn.

3. Working outward toward the bin wall,

lower each jack until they touch the con-

crete and raise the sweep up until there is

1/2” to 1” of clearance between the lower

edge of the back shield and the concrete.

Keep the sweep straight! Fold all jack

handles down after adjusting.

4. Pre-run the sweep around the bin,

stopping about every 1/8 of a revolution

to inspect the clearance following proper

lockout/tag out and bin entry procedures.

Adjust as necessary to maintain adequate

clearance. Always keep the sweep straight

and even pressure on all jacks. Check that

the sweep functions properly in both auto-

matic and manual mode. the sweep should

not be lowered prior to filling.

Park the sweep so the bottom edge of the

auger back shield is in the center of the

outer most intermediate discharge well.

Intermediate discharge well should not

exceed 10’ center to center.

Cover the motors (after cooled) with vinyl

covers provided prior to filling the bin.

Covers need to be removed prior to start

up.

WHEN RUNNING IN MANUAL MODE,

MONITOR THE AMP METER AND NEVER

EXCEED THE FULL LOAD AMPERAGE OR

DAMAGE MAY OCCUR!

Rotation Direction of tires