Fig. 3 fig. 2, Installing bearing support kit – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1319 User Manual

Page 2

Bearing Support Kit PNEG-1319

Page 2 of 4

1. Turn off and lock out power source.

2. Loosen set screws on bearings.

3. Slide bearing away from sprocket to make room

to guide end plates around channels.

4. Replace standard grease zerks with 90° grease

zerks on both bearings. Make sure the 90° grease

zerk is turned as shown in Figure 2, so the zerks

are accessible.

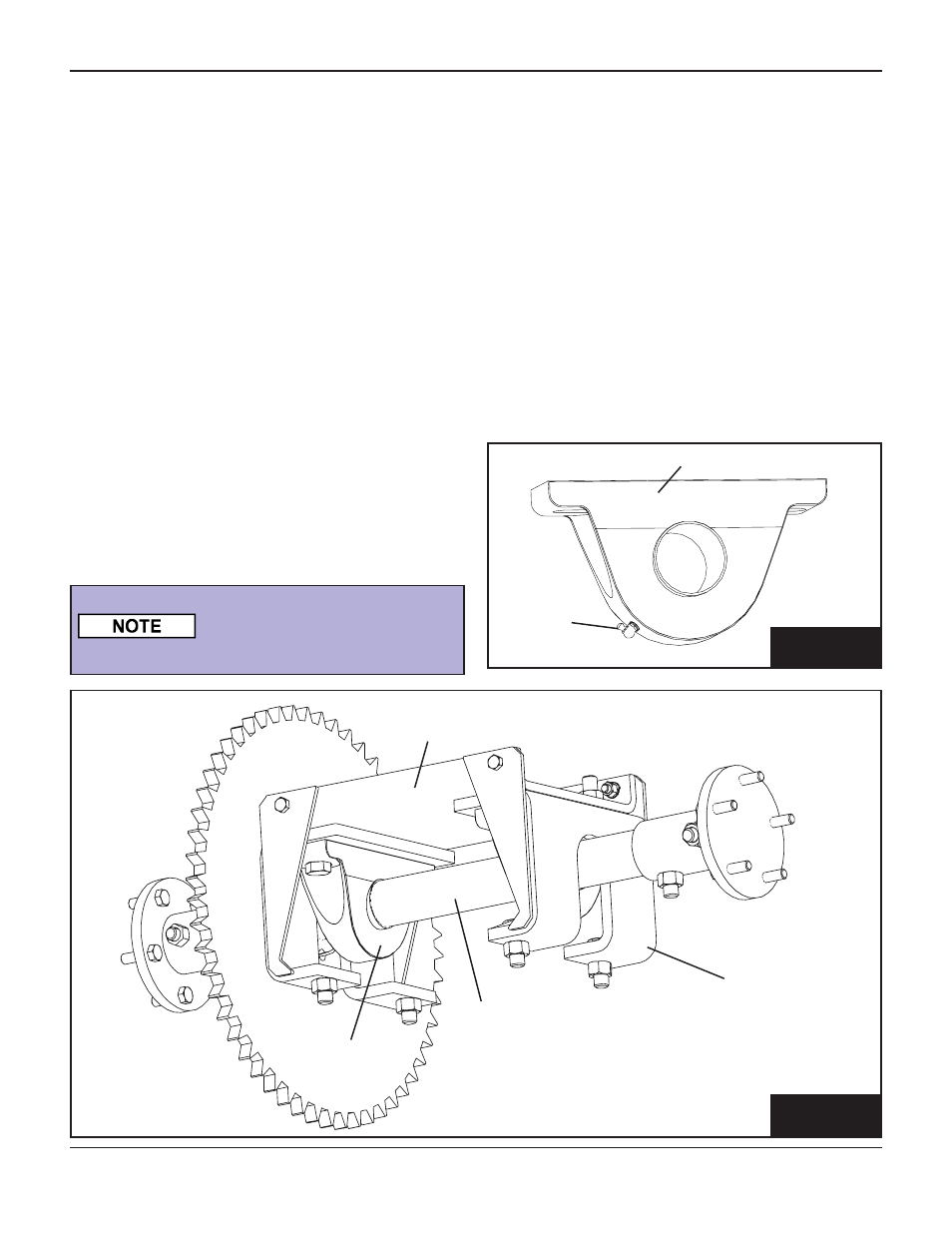

5. Turn the bearings so the base is facing up before

attaching the bearing mount end plates as shown

in Figure 3.

6. Guide bearing mount end plates onto shaft and

hook under the channels, lining up the bolt holes

with the holes where the bearings were previously

attached. (See Figure 1.) Fasten bearing mount

end plates to channels using (4) 5/8" x 2-1/2" Zinc

GR8 bolts, beveled washers, lock washers, and

hex nuts as shown in Figure 4 & 5.

Make sure bearing mount end

plates are fully tightened so

bearings slide under plates

without hitting the channels.

7. Attach the bearing mount top plate to the bearing

mount end plates using (4) 3/8" x 1-1/4" GR5 bolts

with split lock washers and hex nuts. Bolt heads

should be against the end plates as shown in

Figure 4 & 5.

8. Slide bearings into position under bearing mount

end plate, the holes should line up.

9. Fasten the bearings to the end plates and top plate

using (4) 5/8" x 3" GR8 bolt with lock washers and

hex nuts. The bolt heads should rest against the

bearings. Tighten set screws on bearings. (See

Figure 4 & 5.)

INSTALLING BEARING SUPPORT KIT

FIG. 3

FIG. 2

BEARING

90°

GREASE

ZERK

BEARING

MOUNT END

PLATE

BEARING MOUNT

TOP PLATE

BEARING

SHAFT