Operation of control kit, Discharge gate ground control kit – Grain Systems Bucket Elevtors, Conveyors, Series II Sweeps PNEG-1902 User Manual

Page 5

PNEG-1902

Page 5 of 7

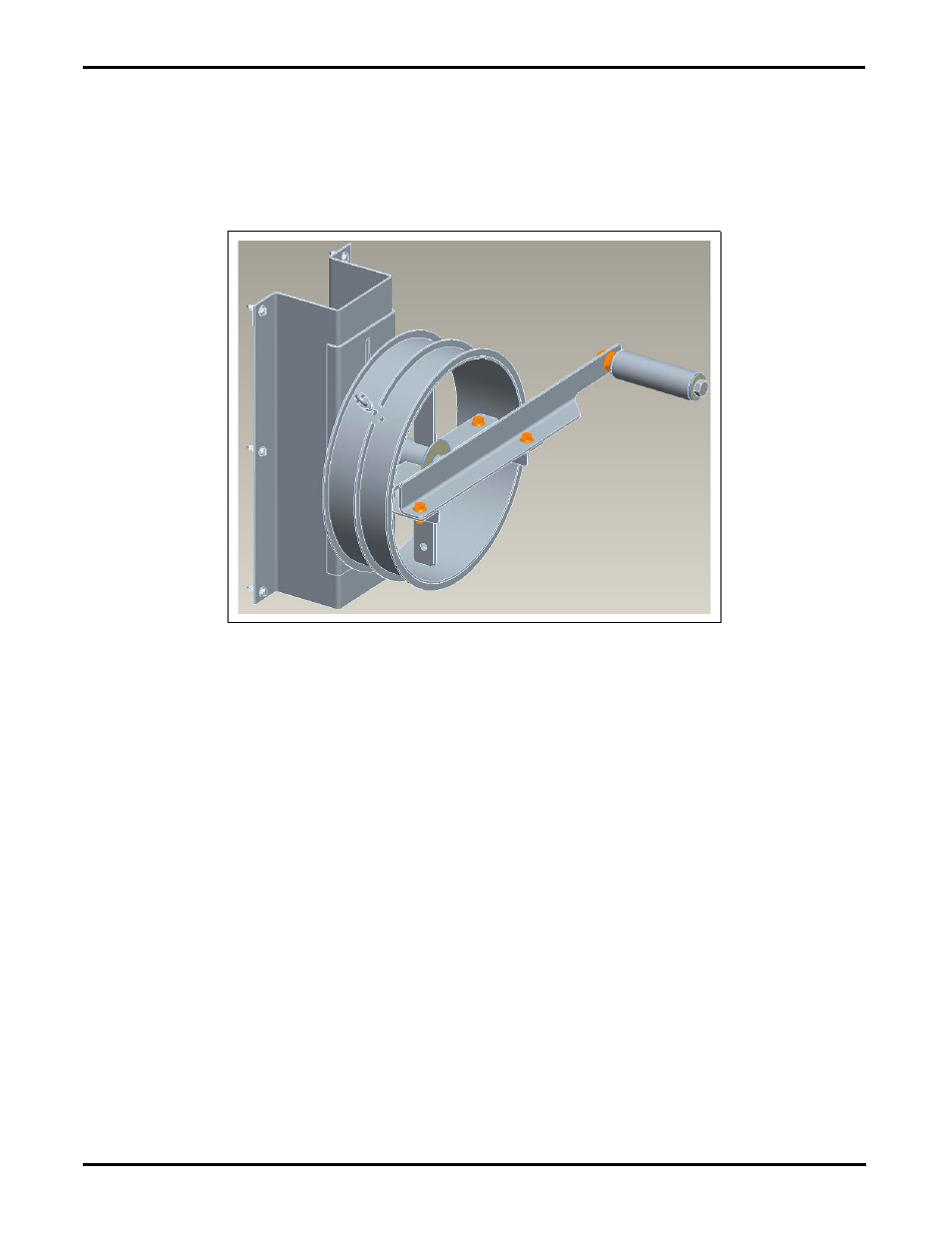

Discharge Gate Ground Control Kit

6. Completely open the discharge gate and wrap the cable six (6) times counterclockwise around the

outside section (closest to you) of the discharge gate control wheel starting outside and working

towards the middle. Use cable clamp to secure the cable to the control wheel. Cross the cable to

the inside section of the discharge gate control wheel and wrap the cable two (2) times starting at

the middle and working towards the outside.

NOTE: The cable should never be wrapped on top of itself.

Figure 8

7. Make sure the discharge gate is still completely open.

8. Route the cable back through the idler pulleys and down to the ground control wheel.

9. Wrap the cable two (2) times counterclockwise around the outside section of the discharge gate

control wheel starting outside and working towards the middle. Use cable clamp to secure the cable

to the control wheel. Cross the cable to the inside section of the discharge gate control wheel and

wrap the cable six (6) times starting at the middle and working towards the outside.

NOTE: The cable should never be wrapped on top of itself.

10. Splice the ends of the cable with two (2) cable clamps. With the gate completely open, the splice

should be at least 10' away from the pulleys and control wheels.

11. Slide the ground wheel bracket down to take up any slack in the cable and tighten in place.

12. Check the installation by turning the ground wheel clockwise to fully close the discharge gate and

counterclockwise to fully open the gate without any restrictions from the cable splice or the clamps

on the control wheels.

Operation of Control Kit

Each control system should be marked to identify which discharge gate is being controlled.

Each control system should be marked after installation to clearly identify whether the discharge gate is

open or closed.