Figure 3 – Banks Power Ford Motorhomes: (Gas ’93 - 97 7.5L Class-C) PowerPack system (Class-C) For Use w_ 460 EFI Engine User Manual

Page 7

NOT kink or deform the tubes.

9.

unbolt and remove exhaust manifolds from

engine, loosen any brackets attached to

exhaust manifold bolts as required (other side of

brackets may be left attached to engine during

manifold removal). remove sparkplug wire heat

shields, if equipped. discard heat shields as they

will not be reused.

10.

inspect the exhaust manifold flange

surfaces on the cylinder heads. remove

any foreign material from these surfaces that

might prevent proper manifold sealing. if cylinder

heads have been heavily eroded from leaking

factory manifolds, exhaust manifold gaskets will

be required, or the heads must be removed and

the exhaust flange area surfaced as necessary.

otherwise, no gaskets are used between the

banks torquetube manifolds and cylinder head,

as the torquetubes have machined flanges like

the original factory iron manifolds.

11.

install right-hand banks torquetube

exhaust manifold from under the vehicle.

see caution note on jacking and raising vehicle in

general installation practices section. install all

bolts finger-tight, then tighten bolts from the

center out. use a dab of anti-seize lubricant

(provided) on the bolt threads where they enter

the head. see Figure 1 for bolt locations.

reconnect air injection tube (if used) to two-bolt

flange at rear of exhaust manifold head flange.

(only manifolds for air injected engines will have

this flange.)

use new gasket, provided, two

1

⁄

4

-28 x

3

⁄

4

hex bolts,

and four

1

⁄

4

” circle-lock washers. washers are

used in pairs on each bolt, the ramps on the

surface of each washer must face each other

when installed on bolt. see Figure 1 for proper

washer installation.

12.

install left-hand banks torquetube exhaust

manifold from under the vehicle. use two

bolts to temporarily hang and position the

manifold on the cylinder head. thread egr tube

and air injection tube (if equipped) in fittings on

banks exhaust manifold. note: early-model air

injection systems require an adapter nipple

(supplied) for hook-up see Figure 2.

because of the tight confines, we suggest that

the egr tube (if equipped) be tightened into the

manifold with the manifold loosely attached to

the head (this allows for some additional freedom

of movement). in some cases, the egr and air

injection tubes may have to be tightened with the

manifold completely separated from the head,

then bolted to the head when wrenching the

tubes is completed. air injection tube may be

loosened from its upper support bracket to aid in

alignment during installation. a dab of anti-seize

on the tube threads will aid in assembly.

once this procedure is complete, install remaining

manifold bolts finger tight, with anti-seize applied.

see Figure 2 for bolt location. bolt dipstick tab to

spacer on manifold bolt as indicated in Figure 2.

13.

reinstall sparkplugs and sparkplug wires.

do not reinstall factory spark plug heat

shields. they are unnecessary with the torque

tubes, and may cause poor engine performance

due to arcing.

14.

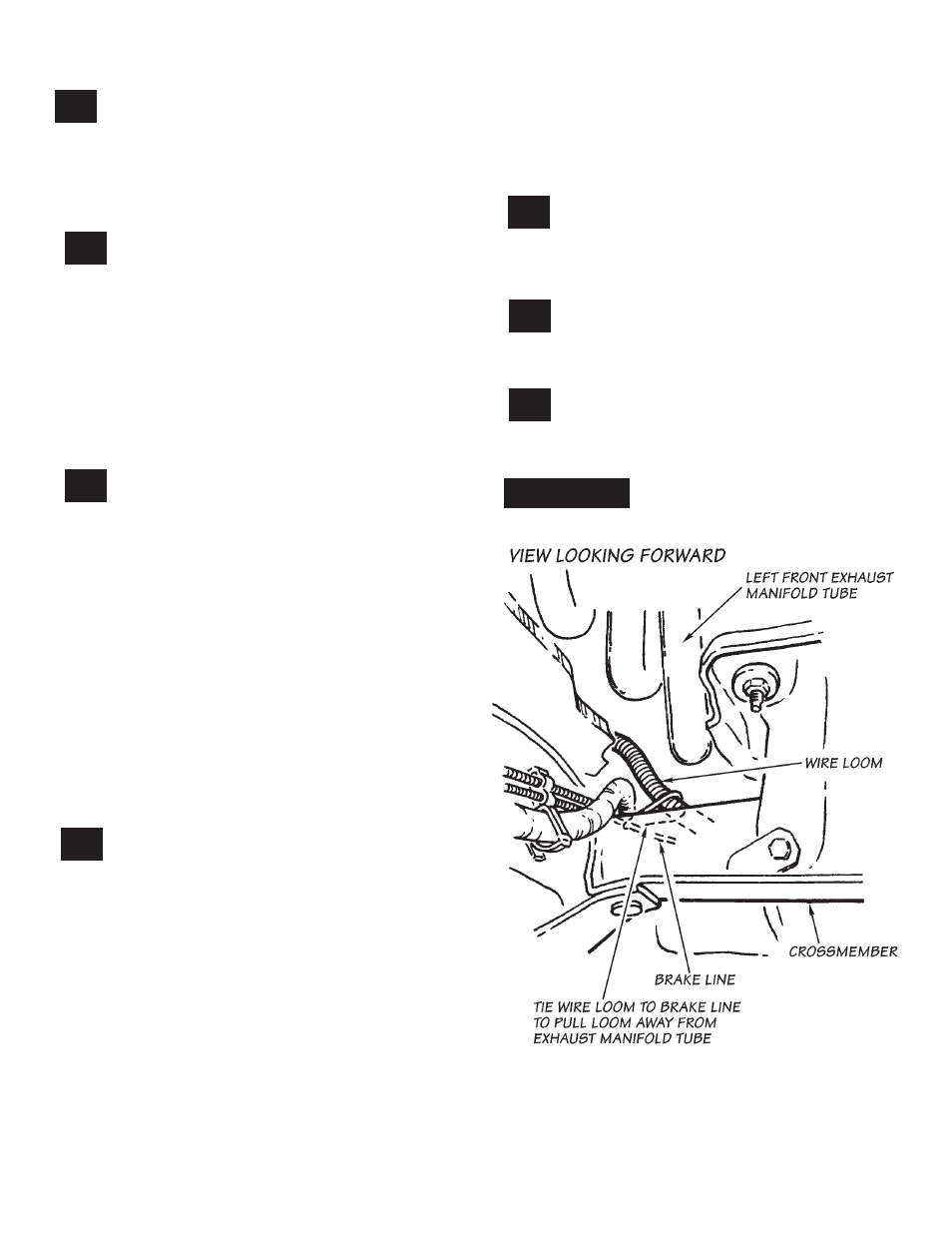

use a plastic cable tie, provided, to pull

wire loom away from left front manifold

tube as shown in Figure 3 by tying wire loom to

brake line.

15.

install new y-pipe between torquetube

manifold outlets and catalytic converter.

figure 3

7

96360 v.4.0

7