Figure 8 figure 7 – Banks Power GM Motorhomes: (Gas ’01 - 10 8.1L Workhorse) PowerPack & Stinger systems '01-04 Class-A MH, P-series User Manual

Page 8

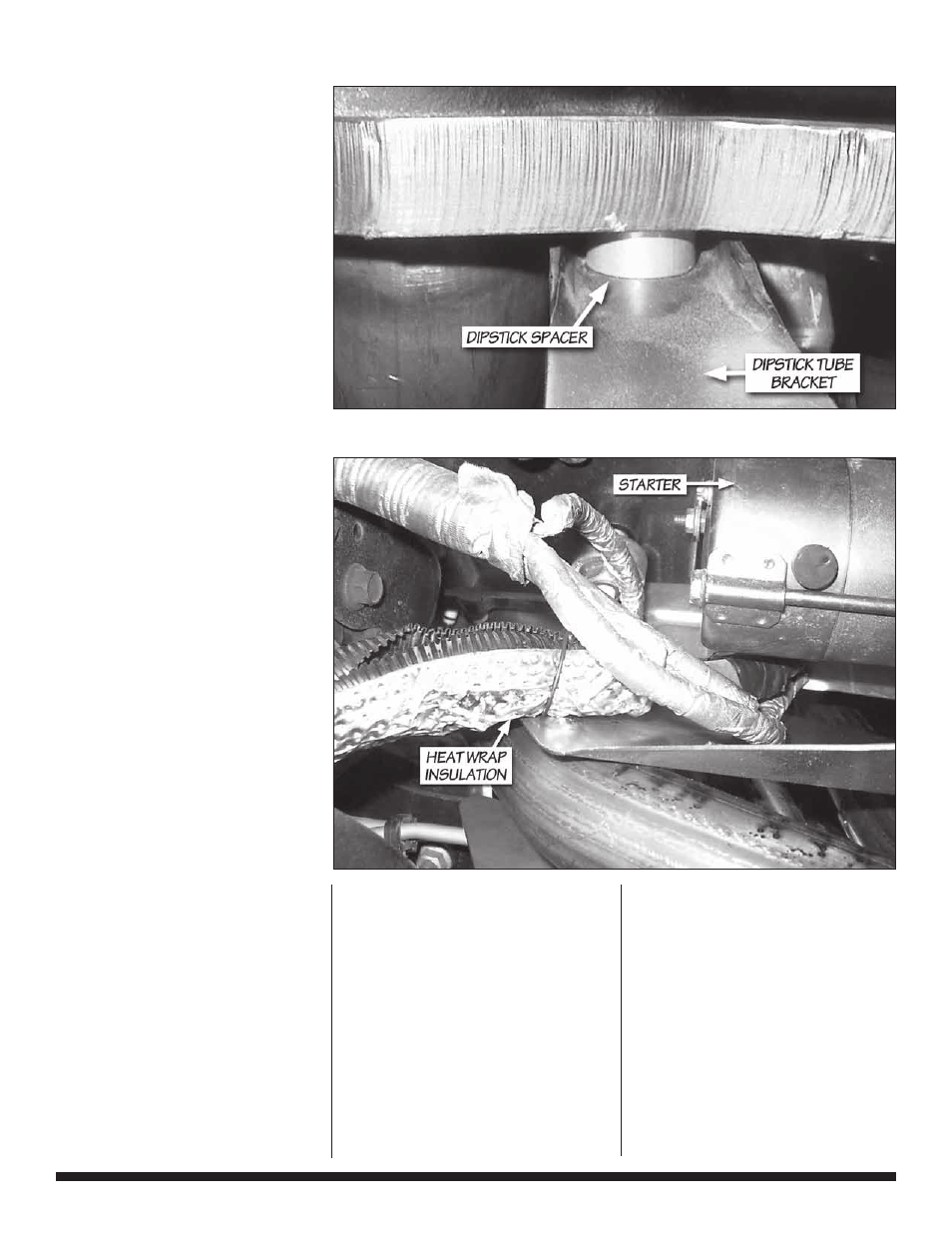

17.

Reinstall the dipstick

tube and o-ring. Using

the single 8 mm x 30 mm

manifold bolt and spacer

provided, attach the bracket

to the flange as shown in

Figure

7

. Torque the 8 mm

x 30 mm bolt to 26 ft-lbs.

Re-secure the bracket to the

alternator support using the

bolt previously removed.

Re-install the spark plugs

and spark plug wires in their

original locations.

18.

If applicable, bolt the

EGR tube to the TorqueTube

manifold using the supplied:

(1) EGR gasket

(2)

5

⁄

16

-18 x 1.0” bolts

(2)

5

⁄

16

-18 crimplock nuts

(4)

5

⁄

16

washers

It may be necessary to rotate

the flange on the EGR tube to

align with the flange on the

TorqueTube manifold. Torque

the EGR hardware to 25 ft-lbs.

19.

Attach the supplied

heat wrap insulation to the

starter cable extension, if

installed, using the steel wire

ties provided. Relocate and

insulate wires to shield the

cable from the heat source

(see Figure

8

).

20.

Place a conical seal

in the flare on the right

side headpipe. Attach the

headpipe and conical seal

to the right-side TorqueTube

manifold using

(2)

3

⁄

8

-16 x 1

3

⁄

4

” bolts

(2)

3

⁄

8

SAE washers

Tighten the bolts just enough

to hold the headpipe in place.

21.

Insert the balance tube

onto the installed right side

headpipe. Slide (2) 2

1

⁄

4

”

clamps over the balance tube.

Place a conical seal in the

flare on the left side headpipe.

Attach the headpipe to the

left-side TorqueTube manifold

and balance tube. Insert

the end of the balance tube

into the headpipe. Loosely

assemble the left headpipe to

the TorqueTube using:

(2)

3

⁄

8

-16 x 1

3

⁄

4

-inch bolts

(2)

3

⁄

8

SAE washers

Using th e supplied zip ties,

secure any wire harnesses

away from the

H-pipe (see Figure

9

).

Figure 8

Figure 7

8 |

9 6 4 3 2 v . 5 . 0