Description, Operating temperature, Operating instructions – Velleman VTSSD3 User Manual

Page 6

VTSSD3

08.02.2010

©Velleman nv

6

6. Description

This soldering/desoldering station is designed to meet the present and future needs of the electronic

production industry. The VTSSD3 is engineered to meet the stringent demands of hobbyists,

maintenance personnel and production people alike.

The VTSSD3 is equipped with a self-contained, electronically controlled vacuum pump. The vacuum

pump is maintenance-free. It will not overload with continuous use. The vacuum pump provides a max.

suction of 50cm/Hg (20"/Hg) and is activated by a push-button switch located on the housing. The solder

collector in the hand-piece can easily be removed for cleaning purposes. The internal aluminium cooling

strip prevents the solder from flowing to the tip too quickly and the ventilation slots keep the handle cool.

The VTSSD3s’ electronic circuitry enables the user to install soldering temperatures between 150 and

480°C (302 to 896°F) and desoldering temperatures between 300 and 450°C (572 to 842°F) without

having to replace the tip or the heating element. The soldering iron contains a highly insulated, Japanese-

made ceramic heating element. The desoldering iron is equipped with a precision-wound heating element.

The temperature is maintained to within ± 3°C (± 6°F) of the normal operating temperature through a

PTC sensor (for the ceramic heating element of the soldering iron) and a thermocouple sensor (for the

heating element of the desoldering iron). The heating element heats up very quickly and temperature

corrections are executed swiftly thanks to the exceptionally high maximum temperature. The ergonomic

design and the silicone rubber handgrip improve user comfort.

The revolutionary "zero voltage" switching design also protects voltage- and current-sensitive

components (CMOS devices, etc.) against the damaging current and transient voltage spikes commonly

produced by less efficient, mechanically switched stations. The heating elements are galvanically isolated

from the electrical supply by an isolating transformer that prevents the system from using a max. tension

higher than a (safe) 32VAC. Both the soldering and desoldering iron are equipped with a temperature

control located on the front panel. These controls enable the user to execute rapid and precise

temperature adjustments whenever necessary.

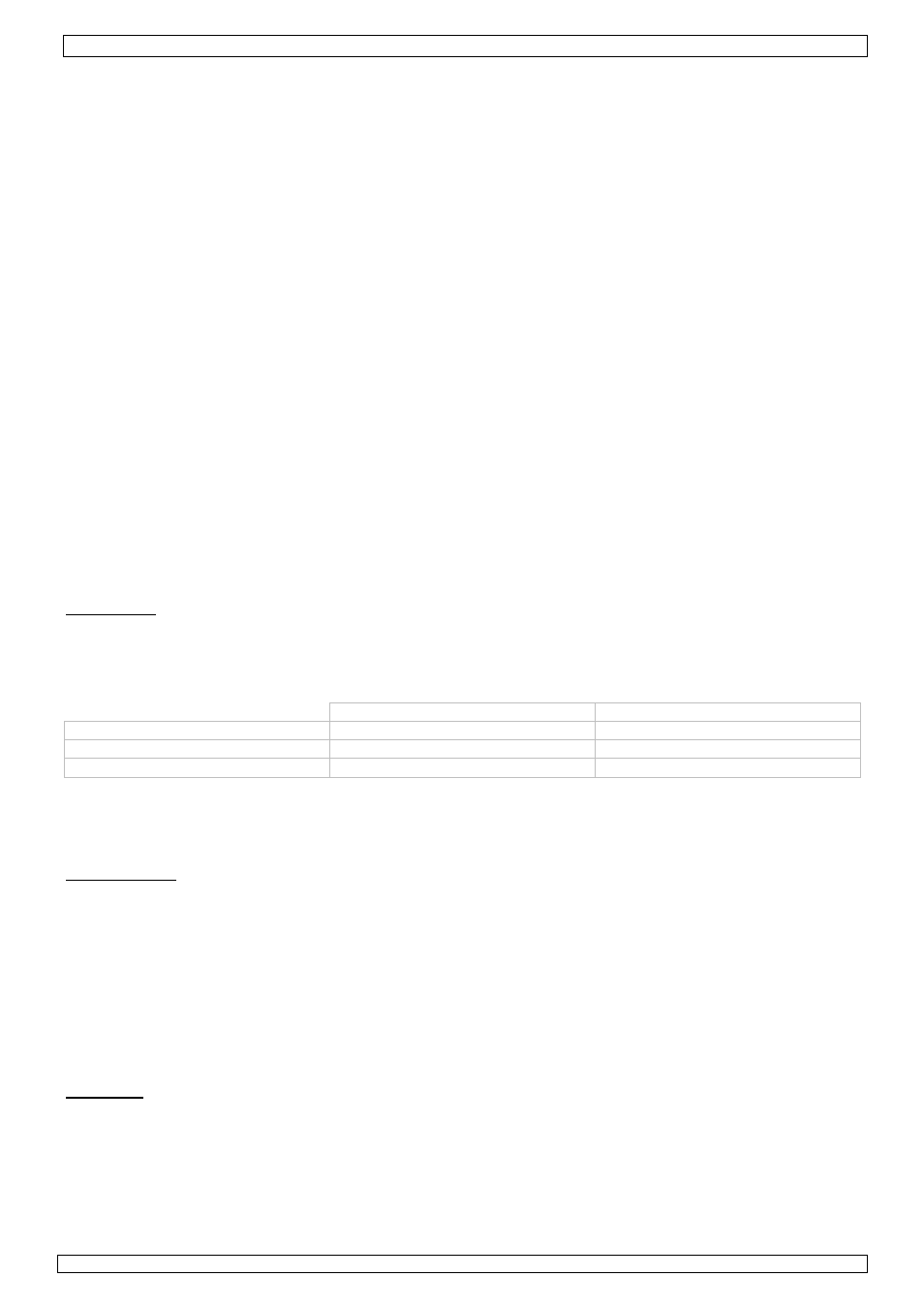

7. Operating Temperature

SOLDERING

The most common soldering alloys used in the electronics industry consist of 60% tin and 40% lead. The

operating temperature of this type of solder is detailed below and can vary from manufacturer to

manufacturer. However, to meet RoHS requirements, these solders are no longer allowed and are

replaced by lead-free solders that require a working temperature which is ±30°C (54°F) higher.

leaded

solder

lead-free

Melting point

215°C (419°F)

220°C (428°F)

Normal Operation

270-320°C (518-608°F)

300-360°C (572-680°F)

Production Line Operation

320-380°C (608-716°F)

360-410°C (680-770°F)

A good joint is assured if the iron's operating temperature is set within the parameters suitable for the

type of solder being used. The solder will flow too slowly if the temperature is too low; if the temperature

is too high, the flux in the solder may burn which will give rise to billowing white smoke. In turn, this will

result in a dry joint or in permanent damage to the PCB.

DESOLDERING

Recommended tip temperatures are detailed below. They can vary from joint to joint.

For a small joint : 320-360°C (or 608-680°F)

For a larger joint : 370-400°C (or 698-752°F)

If the temperature is too low, the solder will flow too slowly and this may cause the tip to clog; you may

burn the PCB if the temperature is too high.

8. Operating instructions

Refer to the illustrations on page 2 of this manual.

Verify whether the operating voltage of the unit is identical to that of the electrical supply.

GENERAL

• Make sure the unit's power switch [1] is in the "OFF"-position.

• Plug in the soldering [2] and desoldering [4] irons. Note that the connectors have a notch so they

only fit in one way. Do not force.

• Slide the vacuum tube to the VAC-connection [5].

• Connect the AC power cord to the mains outlet.