D8t specifications, Engine weights hydraulic controls, Undercarriage – Milton CAT D8T Tier 4 Interim-Stage IIIB User Manual

Page 13: Service refill capacities, Transmission

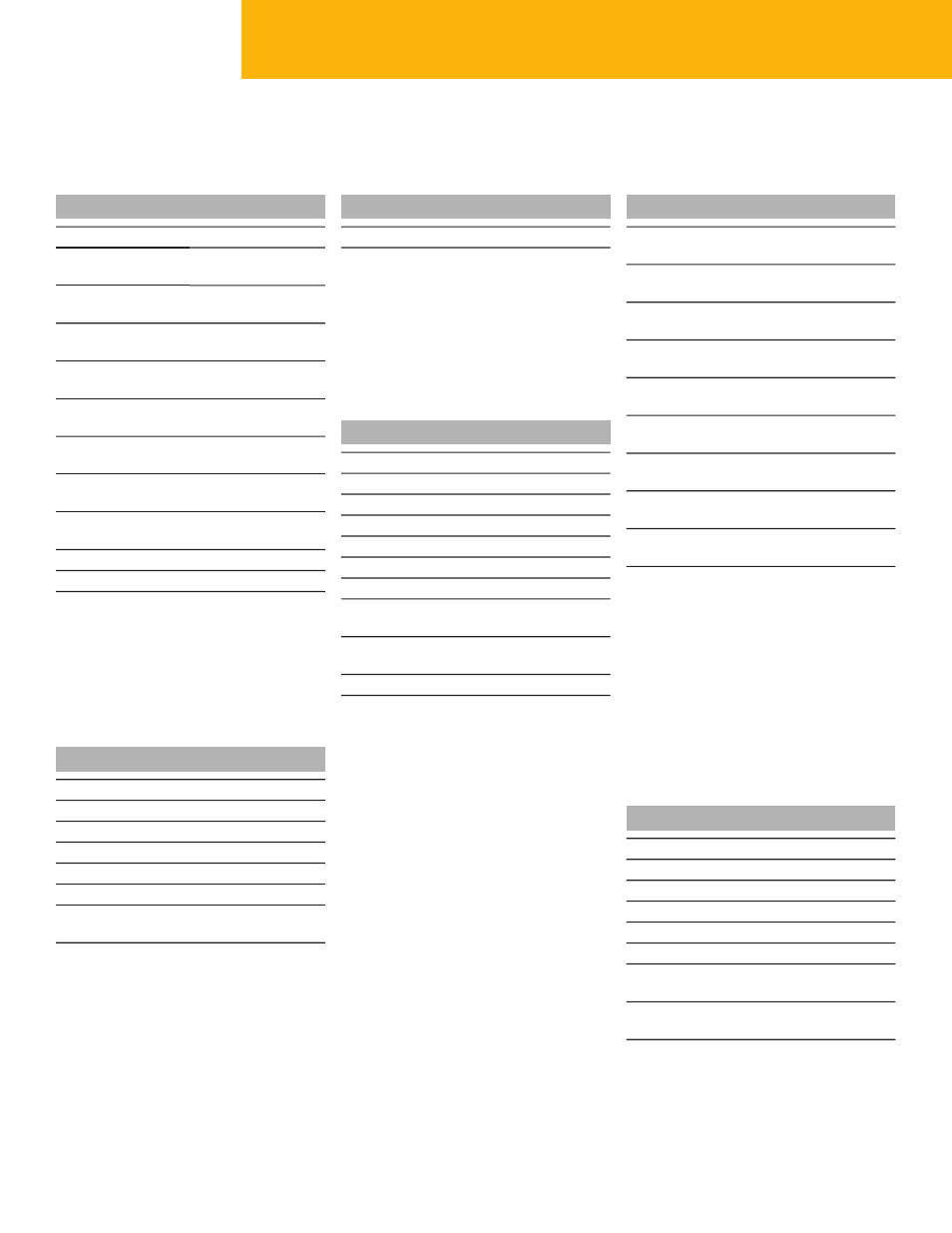

D8T Specifications

Engine

Weights

Hydraulic Controls

Engine Model

Cat

®

C15 ACERT™

Global Emissions

U.S. Tier 4 Interim/

EU Stage IIIB

Gross Power –

SAE J1995

259 kW

348 hp

Gross Power –

ISO 14396

237 kW

318 hp

Gross Power –

ISO 14396 (DIN)

322 hp

Net Power –

231 kW

310 hp

SAE J1349

Net Power –

231 kW

310 hp

Undercarriage

Bulldozer Relief

Valve Setting

ISO 9249

Shoe Type

Moderate Service

Net Power –

314 hp

Width of Shoe

610 mm

24 in

Valve Setting

ISO 9249 (DIN)

Shoes/Side

44

Net Power –

231 kW

310 hp

Grouser Height

78 mm

3 in

Valve Setting

EU 80/1269

Pitch

216 mm

8.5 in

Bore

137 mm

5.4 in

Ground Clearance

618 mm

24.3 in

Valve Setting

Stroke

172 mm

6.75 in

Displacement

15.2 L

928 in

3

Track Gauge

2082 mm

82 in

Length of Track

3207 mm

10.5 ft

Steering

• Engine ratings apply at 1,850 rpm.

on Ground

• Net power advertised is the power available

at the flywheel when the engine is equipped

Ground Contact

Area

3.58 m

2

5,554 in

2

(4,351 psi).

with fan, air cleaner, muffler, and alternator.

• No derating required up to 3566 m

Track Rollers/Side

8

(11,700 ft) altitude, beyond 3566 m

Number of

1 per side (optional)

(11,700 ft) automatic derating occurs.

Carrier Rollers

four valves.

• Positive Pin Retention Track.

Service Refill Capacities

Fuel Tank

643 L

170 gaI

Cooling System

77 L

20.3 gal

Transmission

Engine Crankcase*

38 L

10 gal

Powertrain

155 L

41 gal

1 Forward

Final Drives (each)

12.5 L

3.3 gal

2 Forward

Roller Frames (each) 65 L

17.2 gal

3 Forward

Pivot Shaft

40 L

10.6 gal

1 Reverse

Compartment

2 Reverse

Hydraulic Tank

75 L

19.8 gal

3 Reverse

* With oil filters.

1 Forward –

Operating Weight

39 795 kg 87,733 lb

Shipping Weight

30 490 kg 67,219 lb

• Operating Weight: Includes hydraulic

controls, blade tilt cylinder, coolant,

lubricants, 100% fuel, ROPS, FOPS cab,

SU-Blade, Single-Shank Ripper, 610 mm

(24 in) MS shoes, and operator.

• Shipping Weight: Includes coolant,

lubricants, 20% fuel, ROPS, FOPS cab,

and 610 mm (24 in) MS shoes.

Pump Type

Piston-type, Variable

Displacement

Pump Output

276 L/min 73 gal/min

(Steering)

Pump Output

226 L/min 60 gal/min

(Implement)

Tilt Cylinder Rod

130 L/min 34 gal/min

End Flow

Tilt Cylinder Head

170 L/min 45 gal/min

End Flow

24 000 kPa 3,480 psi

Tilt Cylinder Relief

24 000 kPa 3,480 psi

Ripper (Lift) Relief

24 000 kPa 3,480 psi

Ripper (Pitch) Relief 24 000 kPa 3,480 psi

39 200 kPa 5,700 psi

• Steering Pump output measured at

2,300 rpm (pump speed) and 30 000 kPa

• Implement Pump output measured at

1,850 rpm and 6895 kPa (1,000 psi).

• Electro-hydraulic pilot valve assists

operations of ripper and dozer controls.

A standard hydraulic system includes

• Complete system consists of pump, tank

with filter, oil cooler, valves, lines, linkage

and control levers.

3.4 kph

2.1 mph

6.1 kph

3.8 mph

10.6 kph

6.6 mph

4.5 kph

2.8 mph

8 kph

5 mph

14.2 kph

8.8 mph

618.5 N

139 lbf

Drawbar Pull (1000)

2 Forward –

338.2 N

76 lbf

Drawbar Pull (1000)

3 Forward –

186.9 N

42 lbf

Drawbar Pull (1000)

13