VEGA VEGASWING 66 - transistor (NPN-PNP) User Manual

Page 15

15

4 Mounting

VEGASWING 66 • - transistor (NPN/PNP)

43757-EN-130322

Fig. 9: Inflowing medium

To make sure the tuning fork of VEGASWING 66 generates as little

resistance as possible to product flow, mount the sensor so that the

surfaces are parallel to the product movement.

Due to the effects of agitators, equipment vibration or similar, the level

switch can be subjected to strong lateral forces. For this reason, do

not use an overly long extension tube (optional) for VEGASWING 66,

but check if you can mount a short level switch VEGASWING 66 on

the side of the vessel in horizontal position.

Extreme vibration or tremors, caused e.g. by agitators or turbulence

in the vessel, can make the long extension tube of VEGASWING 66

vibrate in resonance. This leads to increased stress on the upper weld

joint. Should a longer tube version be necessary, you can provide a

suitable support directly above the tuning fork to secure the extension

tube.

This measure applies mainly to applications in Ex areas of category

1G or WHG as well as to ship classifications. Make sure that the tube

is not subject to bending stress due to this measure.

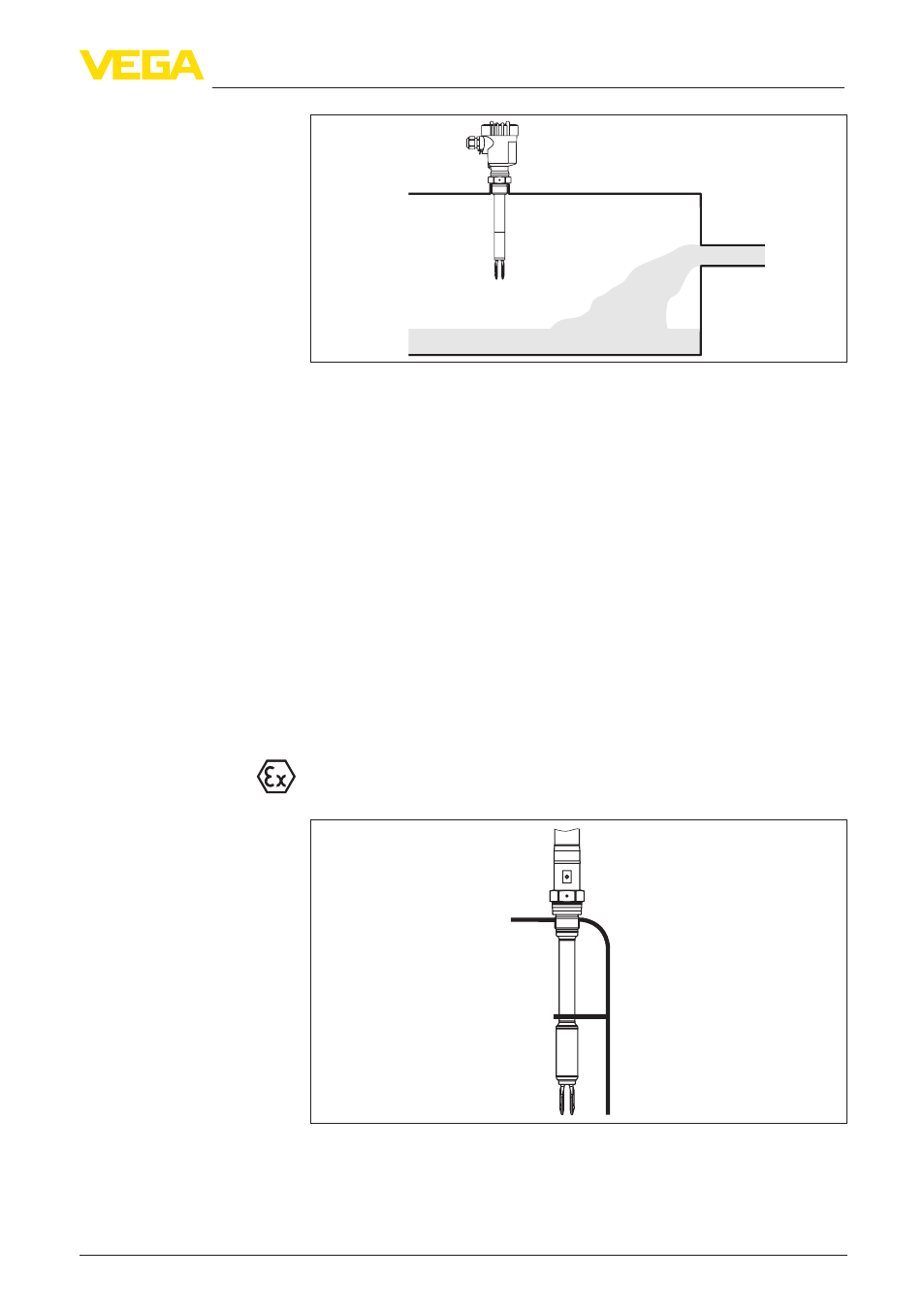

Fig. 10: Lateral straining of VEGASWING 66

The second seal of the gas-tight leadthrough (option) prevents an

uncontrolled leakage of the medium. The service life of the gas-tight

Flows

Agitators

Gas-tight leadthrough