Measurement error during emptying, Constant level, Filling – VEGA VEGAFLEX 81 Foundation Fieldbus User Manual

Page 67

67

9 Diagnostics and service

VEGAFLEX 81 • Foundation Fieldbus

44218-EN-130910

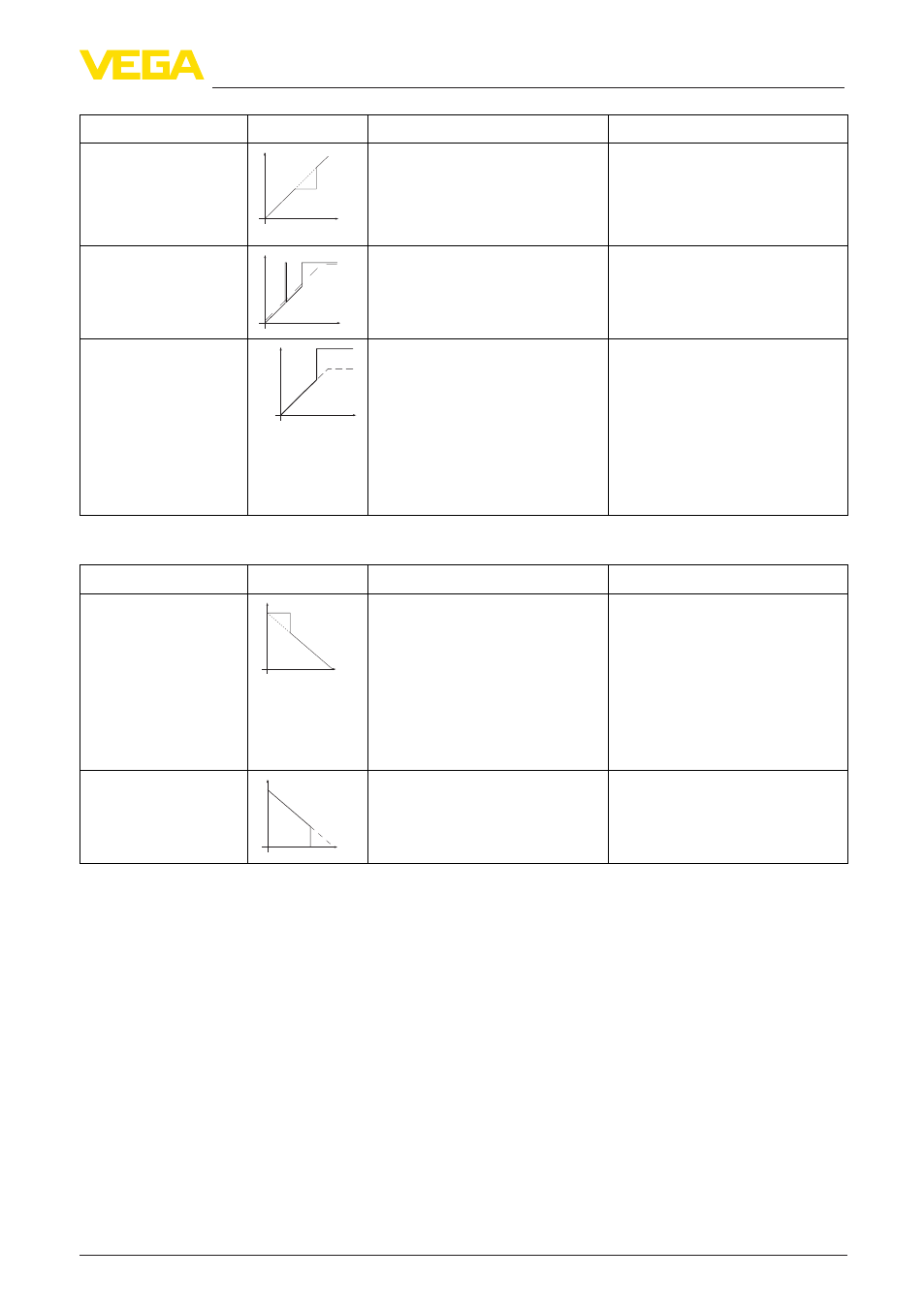

Fault description

Error pattern

Cause

Rectification

4. Measured value re-

mains momentarily

unchanged during fill-

ing and then jumps to

the correct level

Level

time

0

– Turbulence on the product

surface, quick filling

– Check parameters, change if

necessary, e.g. in dosing ves-

sel, reactor

5. Measured value

jumps sporadically to

100 % during filling

Leve

l

time

0

– Changing condensation or

contamination on the probe

– Carry out a false signal sup-

pression

6. Measured value

jumps to ≥ 100 % or

0 m distance

Leve

l

time

0

– Level echo is no longer

detected in the close range

due to false signals in the close

range. The sensor goes into

overfill protection mode. The

max. level (0 m distance) as

well as the status message

"Overfill protection" are output-

ted.

– Eliminate false signals in the

close range

– Check installation conditions

– If possible, switch off the func-

tion "Overfill protection"

Measurement error during emptying

Fault description

Error pattern

Cause

Rectification

7. Measured value re-

mains unchanged in

the close range during

emptying

Level

time

0

– False echo larger than the level

echo

– Level echo too small

– Eliminate false signals in the

close range

– Remove contamination on the

probe. After having removed

the source of the false signals,

the false signal suppression

must be deleted.

– Carry out a new false signal

suppression

8. Measured value re-

mains reproducible

in one position during

emptying

Level

time

0

– Stored false signals in this

position are larger than the

level echo

– Delete false signal memory

– Carry out a new false signal

suppression

The below tables show typical examples for application-relevant

measurement errors with bulk solids. There are two measurement

errors:

•

Constant level

•

Filling

•

Emptying

The images in column "Error pattern" show the real level with a bro-

ken line and the level displayed by the sensor as a continuous line.

Treatment of measure-

ment errors with bulk

solids