Wiha diamond bit – Wiha Tools Bits User Manual

Page 5

167

www.wiha.com

7010 D

Diamond torsion bit, slotted, style C 6.3.

Material:

High grade chrome-vanadium steel, through hardened.

Geometry:

Torsion zone for protecting against premature breakage of bits under load.

Coating:

Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive:

DIN 3126, ISO 1173, style C 6.3.

Application:

For fatigue-free work; ideal bit for frequent working.

Extra:

Non-corrosive coating.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

7011 D

Diamond torsion bit, Phillips, style C 6.3.

Material:

High grade chrome-vanadium steel, through hardened.

Geometry:

Patented torsion zone to prevent premature breaking of the bit when

under stress.

Coating:

Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive:

DIN 3126, ISO 1173, style C 6.3.

Application:

For fatigue-free work; ideal bit for frequent working.

Extra:

Non-corrosive coating.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

7012 D

Diamond torsion bit, Pozidriv, style C 6.3.

Material:

High grade chrome-vanadium steel, through hardened.

Geometry:

Patented torsion zone to prevent premature breaking of the bit when

under stress.

Coating:

Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive:

DIN 3126, ISO 1173, style C 6.3.

Application:

For fatigue-free work; ideal bit for frequent working.

Extra:

Non-corrosive coating.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

7015 D

Diamond torsion bit, TORX

®

, style C 6.3.

Material:

High grade chrome-vanadium steel, through hardened.

Geometry:

Torsion zone for protecting against premature breakage of bits under load.

Coating:

Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive:

DIN 3126, ISO 1173, style C 6.3.

Application:

For fatigue-free work; ideal bit for frequent working.

Extra:

Non-corrosive coating.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

7041 D

Diamond torsion bit, Phillips, style E 6.3.

Material:

High grade chrome-vanadium steel, through hardened.

Geometry:

Patented torsion zone to prevent premature breaking of the bit when

under stress.

Coating:

Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive:

DIN 3126, ISO 1173, style E 6.3.

Application:

For fatigue-free work; ideal bit for frequent working.

Extra:

Non-corrosive coating.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

7042 D

Diamond torsion bit, Pozidriv, style E 6.3.

Material:

High grade chrome-vanadium steel, through hardened.

Geometry:

Patented torsion zone to prevent premature breaking of the bit when

under stress.

Coating:

Extremely wear-resistant diamond-sapphire coating with a long service life.

Drive:

DIN 3126, ISO 1173, style E 6.3.

Application:

For fatigue-free work; ideal bit for frequent working.

Extra:

Non-corrosive coating.

Diamond particles and sapphire particles for optimum torque transfer and

a secure grip in the screw head.

166

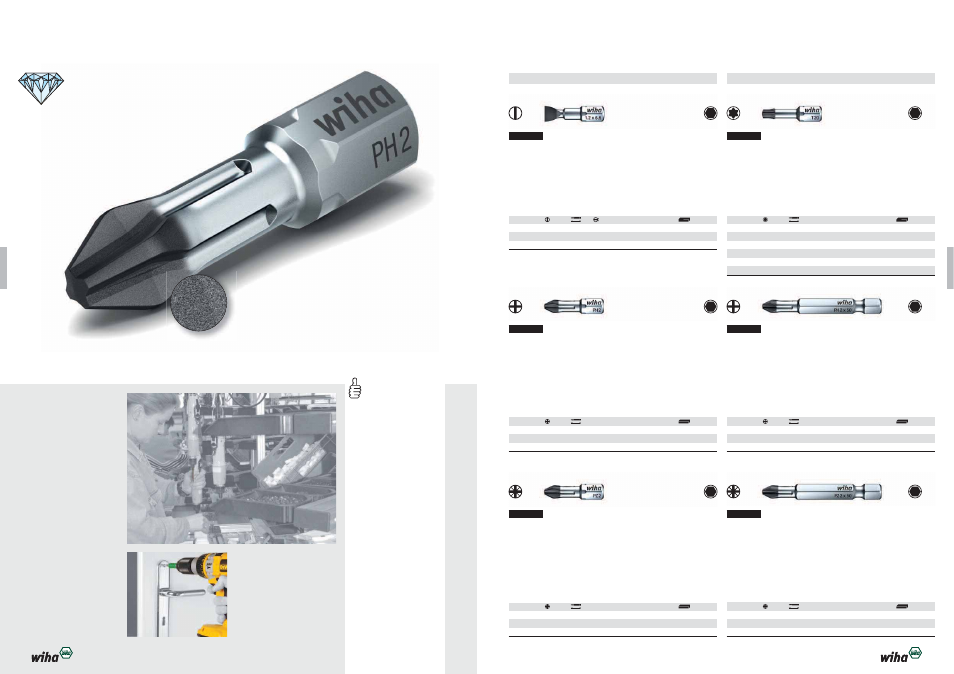

Wiha diamond bit.

Saves strength, time & money.

Finest diamond particles

and sapphire particles

ensure a firm grip a

thousand times over.

The Diamond torsion bit from Wiha scores

on two accounts:

it reduces the amount of pressure that has

to be applied and increases the tool life.

The torsion zone protects against torque

peaks.

Diamond torsion bits supplement

Wiha’s range of high-quality spe-

cial bits. In the area of mechanical

fastening the significantly greater

tool life means substantial cost

reductions. The new Wiha diamond

torsion bits are recognisable by

their silver look and striking black

tip and offer an impressively

secure grip in the screw.

Wiha diamond bit.

• Reduction of:

- Pressure forces to be applied

- Wear and tear of bit and screw

head

- The amount of time to

turn the screw and thus

reduction in the costs of

screw applications

- Cam-out effect

• Extended service life as

a result of the improved

torsion zone

• Nickel coating of the entire

bit for extra-long corrosion

resistance

Style C 6.3 (1/4").

Order-No.

21272 4.5

25

0.6

10

21216

5.5

25

0.8

10

21220 6.5

25

1.2

10

Order-No.

21193 PH1

25

10

21194

PH2

25

10

21196 PH3

25

10

Order-No.

21198 PZ1

25

10

21200

PZ2

25

10

21202 PZ3

25

10

Style C 6.3 and E 6.3 (1/4").

Order-No.

21204 T10

25

10

21206

T15

25

10

21208 T20

25

10

21210

T25

25

10

21212 T30

25

10

21214

T40

25

10

Order-No.

23376 PH1

50

5

23378

PH2

50

5

23380 PH3

50

5

Order-No.

23382 PZ1

50

5

23384

PZ2

50

5

23386 PZ3

50

5