Bosch GEX 125 AC Professional User Manual

Page 15

English | 15

Bosch Power Tools

1 609 929 Y19 | (15.3.11)

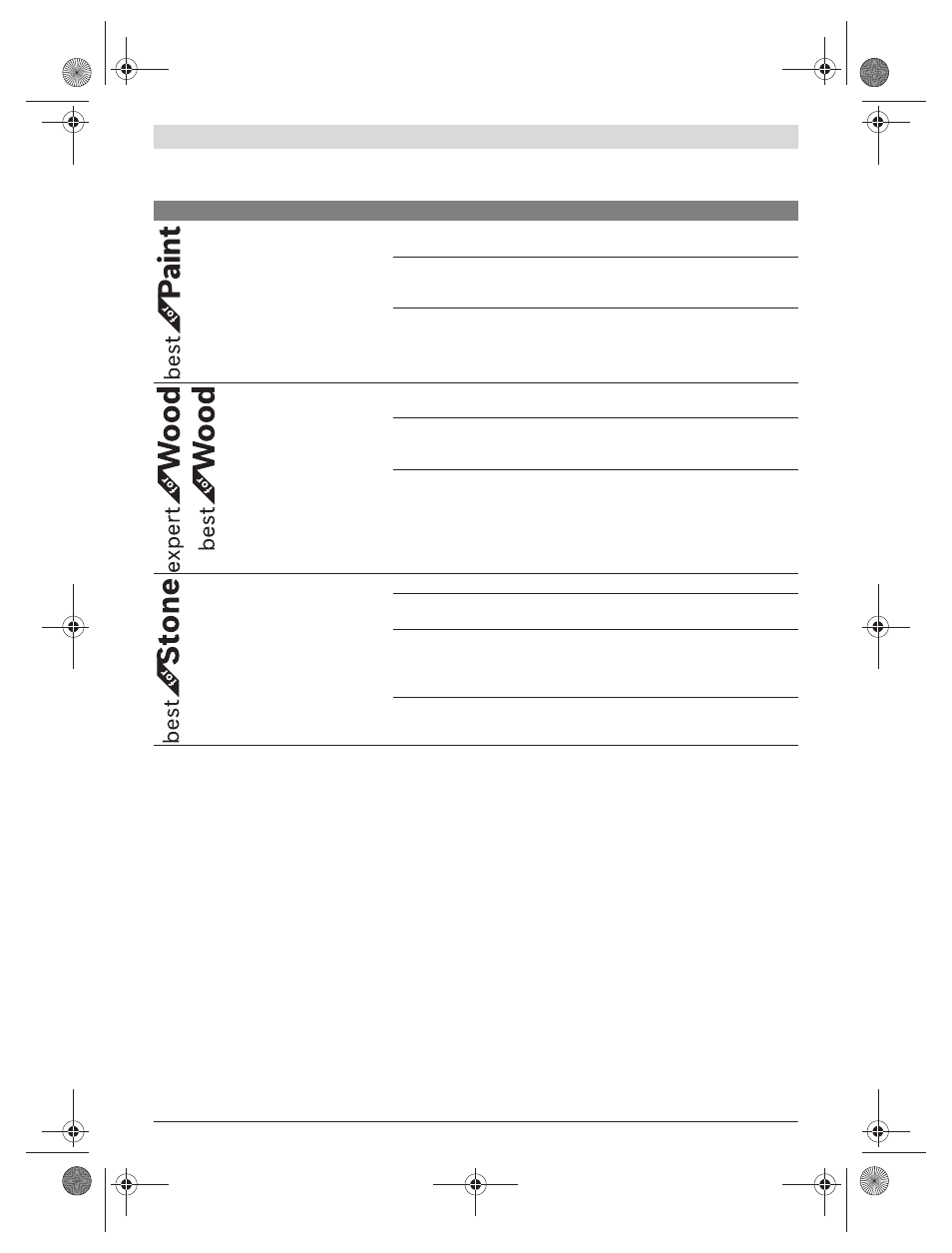

Selecting the Sanding Sheet

Depending on the material to be worked and the required rate of material removal, different sanding sheets are available:

Selection of the Sanding Plate

Depending on the application, the machine can be equipped

with sanding plates of different hardness:

– Soft sanding plate: Suitable for polishing and sensitive

sanding (also for curved surfaces).

– Medium sanding plate: Suitable for all sanding applications

and general-purpose use.

– Hard sanding plate: Suitable for high sanding capacity on

flat surfaces.

Replacing the Sanding Plate (see figure B)

Note: Replace a damaged sanding plate 8 immediately.

Pull off the sanding sheet or polishing tool. Completely un-

screw the screw 11 and take off the sanding plate 8. Attach

the new sanding plate 8 and tighten the screw again.

Note: When attaching the sanding plate, pay attention that

the toothing of the drive element engage into the openings of

the sanding plate.

Dust/Chip Extraction

f

Dusts from materials such as lead-containing coatings,

some wood types, minerals and metal can be harmful to

one’s health. Touching or breathing-in the dusts can cause

allergic reactions and/or lead to respiratory infections of

the user or bystanders.

Certain dusts, such as oak or beech dust, are considered

as carcinogenic, especially in connection with wood-treat-

ment additives (chromate, wood preservative). Materials

containing asbestos may only be worked by specialists.

– As far as possible, use a dust extraction system suitable

for the material.

– Provide for good ventilation of the working place.

– It is recommended to wear a P2 filter-class respirator.

Observe the relevant regulations in your country for the

materials to be worked.

f

Prevent dust accumulation at the workplace. Dusts can

easily ignite.

Material

Application

Grain size

– Paint

– Varnish

– Filling compound

– Filler

For sanding off paint

coarse

40

60

For sanding primer (e.g., for removing brush dashes,

drops of paint and paint run)

medium

80

100

120

For final sanding of primers before coating

fine

180

240

320

400

Expert for Wood

– All wooden materials (e.g.,

hardwood, softwood, chip-

board, building board)

Best for Wood

– Hardwood

– Particle Board

– Building board

– Metal materials

For coarse-sanding, e.g. of rough, unplaned beams and

boards

coarse

40

60

For face sanding and planing small irregularities

medium

80

100

120

For finish and fine sanding of wood

fine

180

240

320

400

– Automotive paint

– Masonry, stone

– Marble

– Granite

– Ceramic

– Glass

– Plexiglas

– Glass-fibre plastics

For pre-sanding

coarse

80

For shaping and braking edges

medium

100

120

For final sanding and forming

fine

180

240

320

400

For polish-sanding and rounding off edges

very fine

600

1200

OBJ_BUCH-424-004.book Page 15 Tuesday, March 15, 2011 3:24 PM