Bosch GCM 12 SD Professional User Manual

Page 45

English | 45

Bosch Power Tools

1 609 929 X01 | (1/7/10)

Starting Operation

f

Observe correct mains voltage! The voltage

of the power source must agree with the

voltage specified on the nameplate of the

machine. Power tools marked with 230 V

can also be operated with 220 V.

Switching On (see figure M)

– To start the machine, press the On/Off

switch 27 and keep it pressed.

Note: For safety reasons, the On/Off switch 27

cannot be locked; it must remain pressed during

the entire operation.

The locking lever 43 will only disengage the re-

tracting blade guard 10 after pressing button 8,

so that the tool arm can be lowered.

– For sawing, you must press button 8 in addi-

tion to actuating the On/Off switch.

Switching Off

– To switch off the machine, release the

On/Off switch 27.

Working Advice

General Sawing Instructions

f

For all cuts, it must first be ensured that the

saw blade at no time can come in contact

with the fence, screw clamps or other ma-

chine parts. Remove possibly mounted aux-

iliary stops or adjust them accordingly.

Protect the saw blade against impact and shock.

Do not subject the saw blade to lateral pressure.

Do not saw warped/bent workpieces. The work-

piece must always have a straight edge to face

against the fence.

Long workpieces must be underlaid or support-

ed at their free end.

Position of the Operator (see figure N)

f

Do not stand in a line with the saw blade in

front of the machine. Always stand aside of

the saw blade. This protects your body

against possible kickback.

– Keep hands, fingers and arms away from the

rotating saw blade.

– Do not cross your arms when operating the

tool arm.

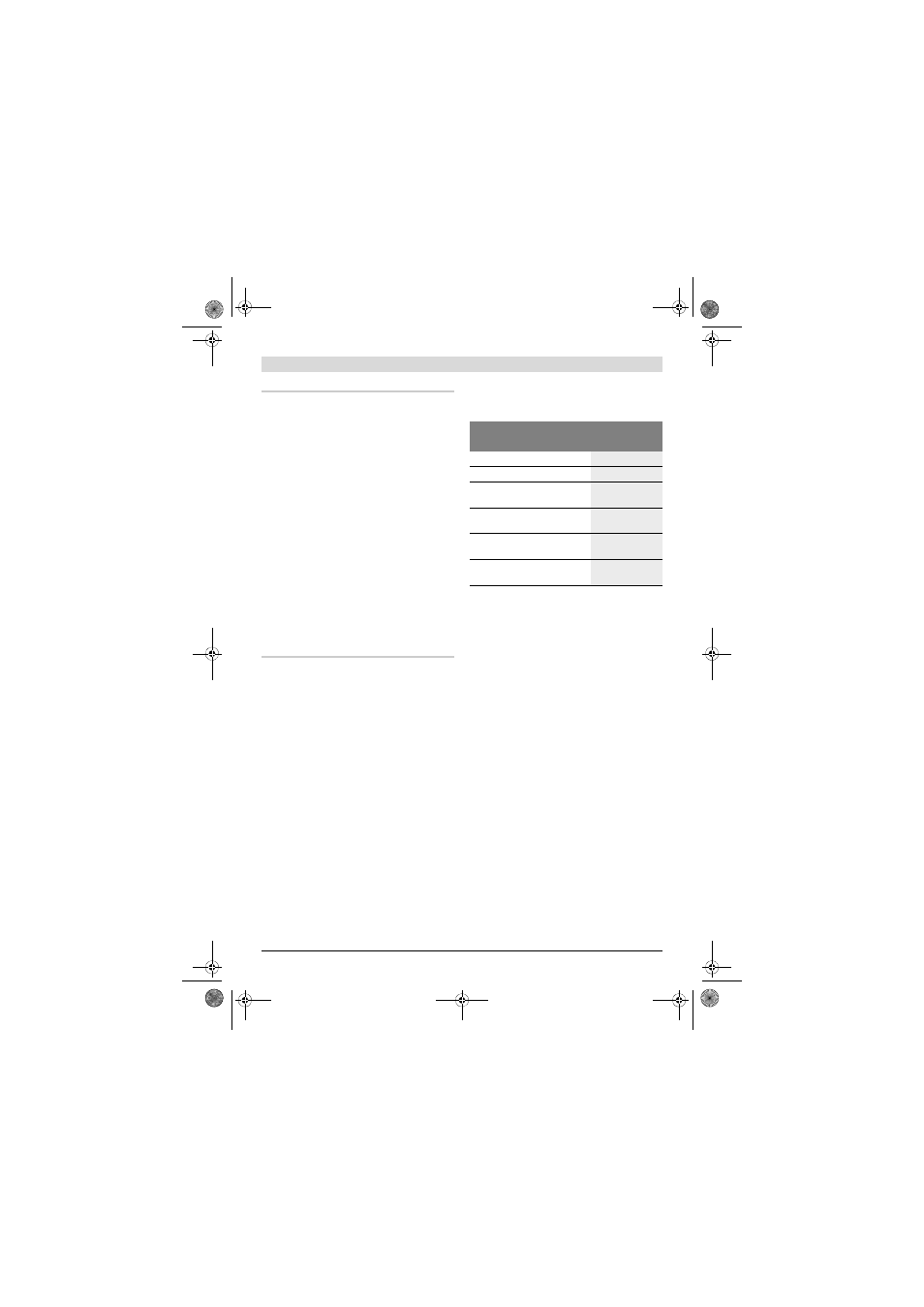

Permissible Workpiece Dimensions

Maximal workpiece sizes:

Minimal workpiece sizes

(= all workpieces that can be clamped left or

right from the saw blade with the provided

quick-action clamp 23):

185 x 40 mm (length x width)

Cutting capacity, max. (0°/0°): 110 mm

Replacing Insert Plates (see figure O)

The red insert plates 12 can become worn after

long use of the machine.

Replace defective insert plates.

– Bring the power tool into the working posi-

tion.

– Unscrew the screws 55 using the provided

Phillips screwdriver and remove the old in-

sert plates.

– Insert the new insert plates.

– Set the bevel angle to 47° (leftward).

– Push locking lever 43 and completely lower

the tool arm.

– Position the insert plate approx. 2 mm away

from the saw blade. Make sure that the saw

blade does not come in contact with the in-

sert plates throughout the complete possible

ripping length.

– Refasten the insert plate with the screws.

– Repeat the work steps for the other insert

plate in the same manner.

Mitre/Bevel Angle

Height x Width

[mm]

Horizontal

Vertical

0°

0°

110 x 305

45°

0°

110 x 217

0°

45°

(leftward)

63 x 305

0°

45°

(rightward)

38 x 305

45°

45°

(leftward)

63 x 217

45°

45°

(rightward)

38 x 217

OBJ_BUCH-1130-002.book Page 45 Thursday, July 1, 2010 11:44 AM