English – Milwaukee K 540 S User Manual

Page 8

5

GB

English

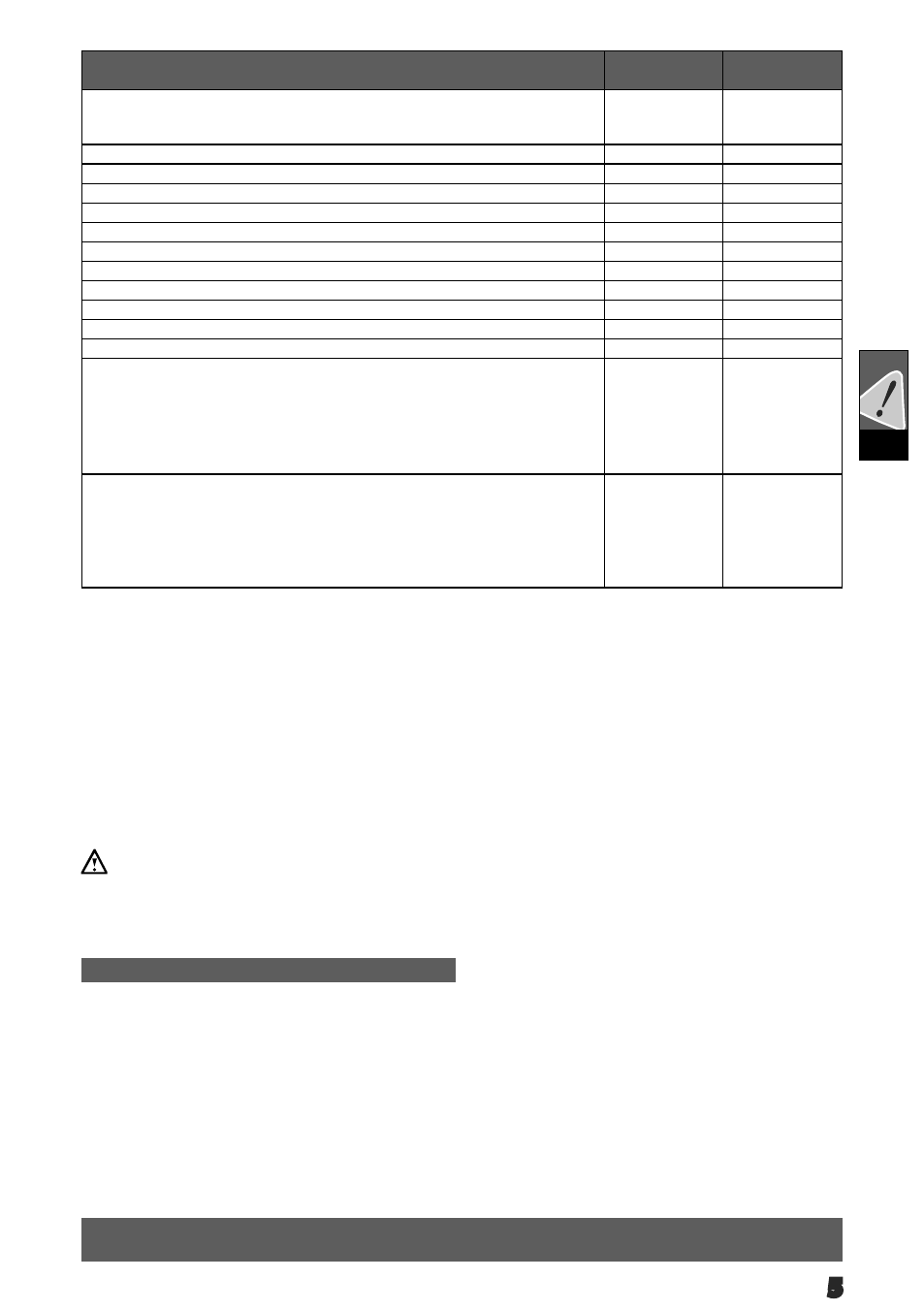

TECHNICAL DATA

Rotary Hammer

K 540 S

(220-240 V)

K 540 S

(110-120 V)

Production code

4181 21 01...

4181 01 01...

... 000001-999999

4181 41 01...

... 000001-999999

Rated input

1100 W

1100 W

Output

550 W

550 W

No-load speed

450 min

-1

450 min

-1

Speed under load max.

430 min

-1

430 min

-1

Rate of percussion under load max.

3000 min

-1

3000 min

-1

Impact energy per stroke according to EPTA-Procedure 05/2009, Chiselling/Drilling

7,5 / 7,5 J

7,5 / 7,5 J

Drilling capacity in concrete

40 mm (SDS-max) 40 mm (SDS-max)

Tunnel bit in concrete, bricks and limestone

65 mm (SDS-max) 65 mm (SDS-max)

Core cutter in concrete, bricks and limestone

105 mm (SDS-max) 105 mm (SDS-max)

Chuck neck diameter

66 mm

66 mm

Weight according EPTA-Procedure 01/2003

6,3 kg

6,3 kg

Noise/Vibration Information

Measured values determined according to EN 60 745.

Typically, the A-weighted noise levels of the tool are:

Sound pressure level (K=3dB(A))

Sound power level (K=3dB(A))

Wear ear protectors!

93,0 dB (A)

104,0 dB (A)

91,5 dB (A)

102,5 dB (A)

Total vibration values (vector sum in the three axes) determined according to EN 60745.

Vibration emission value a

h

Hammer-drilling in concrete:

Uncertainty K =

16,8 m/s

2

1,5 m/s

2

17,5 m/s

2

1,5 m/s

2

Chiselling:

Uncertainty K =

16,7 m/s

2

1,5 m/s

2

15,4 m/s

2

1,5 m/s

2

WARNING

The vibration emission level given in this information sheet has been measured in accordance with a standardised test given in EN 60745 and

may be used to compare one tool with another. It may be used for a preliminary assessment of exposure.

The declared vibration emission level represents the main applications of the tool. However if the tool is used for different applications, with

different accessories or poorly maintained, the vibration emission may differ. This may significantly increase the exposure level over the total

working period.

An estimation of the level of exposure to vibration should also take into account the times when the tool is switched off or when it is running

but not actually doing the job. This may significantly reduce the exposure level over the total working period.

Identify additional safety measures to protect the operator from the effects of vibration such as: maintain the tool and the accessories, keep

the hands warm, organisation of work patterns.

WARNING! Read all safety warnings and all

instructions, including those given in the accompanying

brochure. Failure to follow the warnings and instructions may result

in electric shock, fire and/or serious injury. Save all warnings and

instructions for future reference.

SAFETY INSTRUCTIONS

Wear ear protectors. Exposure to noise can cause hearing loss.

Use auxiliary handle(s), if supplied with the tool. Loss of

control can cause personal injury.

Hold power tool by insulated gripping surfaces, when

performing an operation where the cutting accessory

may contact hidden wiring or its own cord. Cutting accessory

contacting a „live“ wire may make exposed metal parts of the power tool

„live“ and could give the operator an electric shock.

Appliances used at many different locations including open air should be

connected via a residual current device (FI, RCD, PRCD) of 30mA or less.

Always wear goggles when using the machine. It is recommended

to wear gloves, sturdy non slipping shoes and apron.

Sawdust and splinters must not be removed while the machine is

running.

Before doing any work on the machine, pull the plug out of the

socket.

Only plug-in when machine is switched off.

Keep mains lead clear from working range of the machine. Always

lead the cable away behind you.

Do not use diamond core drills on hammer mode.

When working in walls ceiling, or floor, take care to avoid electric

cables and gas or waterpipes.

The dust produced when using this tool may be harmful to health.

Do not inhale the dust. Use a dust absorption system and wear a

suitable dust protection mask. Remove deposited dust thoroughly,

e.g. with a vacuum cleaner.