Installation, Shop air piping layout – Graco 234418 Membrane Air Drying System User Manual

Page 2

Installation

2

309920C

Installation

1.

Before installing air line components, blow out the

pipe line to remove debris. Be sure air to the regula-

tor is clean. Erratic operation or loss of regulation is

usually caused by dirt in the regulator.

2.

Install the Air Drying System as close as possible to

the equipment it serves.

3.

Install air shut-off valve 288798 upstream from the

air system to isolate it for service.

4.

Install system so air flows through filters in the direc-

tion noted on top of filter.

5.

A minimum 1/2” npt piping is recommended. Avoid

using too many fittings, couplings, etc., which will

restrict air flow.

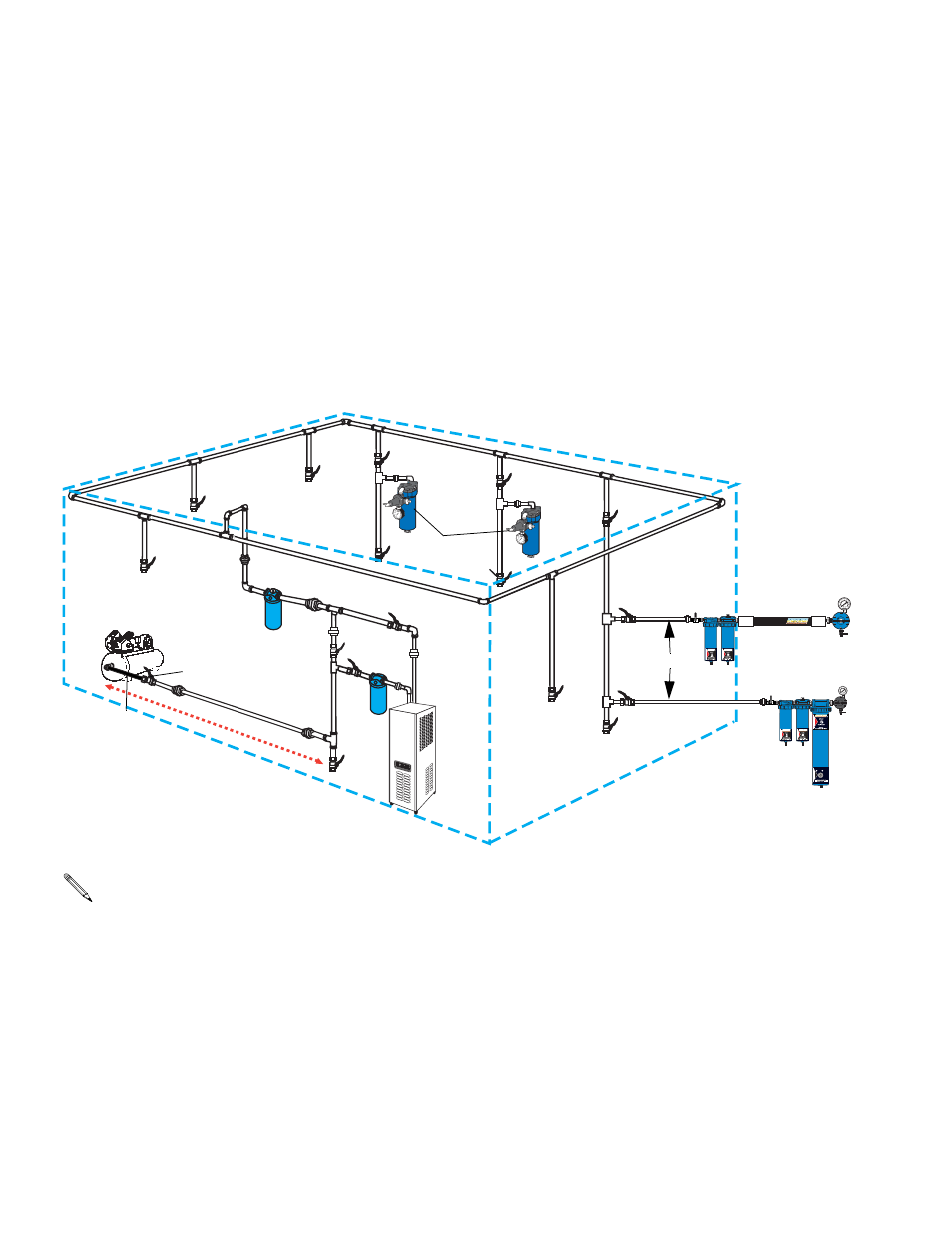

Shop Air Piping Layout

2

4

6

8

1

1

1

1

2

4 6 8

1

SATURA

TED

NORMA

DESICCANT

¨

2

4

6

8

1

1

1

1

2

4 6 8

1

Membrane air

drying system

Desiccant air

drying system

Ball Valve

Drain Valve

Drain

Leg

Air Control unit

or Air Filter

1/2” (13

mm) drops

Main Air Line

3/4” (19 mm) minimum

1-1/4” (32 mm) optimum

Slopes do

wn and aw

ay

Recomm

ended 4” (

117 mm)

drop in 50

’ (15.24 m

) galvaniz

ed

Coalescer

Air

Filter

Compressor

Flexible hose

between compressor

and stand pipe

15-20

ft. (4

.6-6.1

m)

•

Main Air Line stand pipe should not be smaller than compressor outlet size.

•

A minimum of 25 ft. (7.62 m) from compressor to first filter outlet is required to cool air [50 ft. (15.24 m) optimum]

OR

Main Air

Shut-off Valve