Maintenance – Zenoah GZ3500T User Manual

Page 14

GZ3500T

GB-14

knob

air cleaner cover

filter elements

NGK

CMR7H

Fuel filter

Oiling port

Oil filter

Oiling port

Grease port

Sprocket

7. Maintenance

When returning the filter, use a pinch not to be folded the suc-

tion pipe.

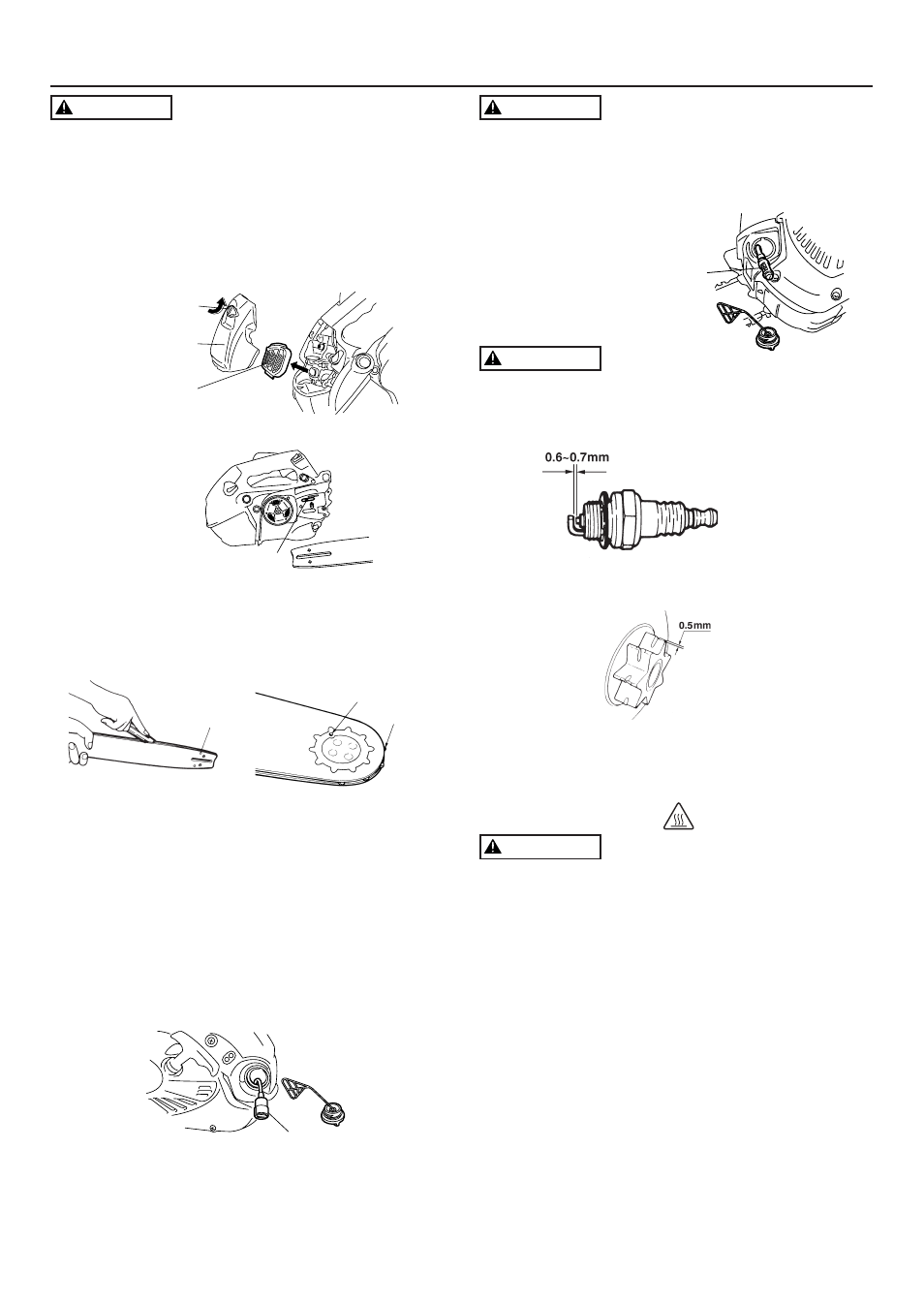

3. Oil filter

1.

With a wire hook, take out the oil filter from the feeding

port.

2.

Wash the filter with gasoline.

When returning the filter, use a pinch not to be folded the suc-

tion pipe.

4. Spark plug

Clean the electrodes with a wire brush and reset the gap to

0.6 mm as necessary.

5. Sprocket

Check for cracks and for excessive wear interfering with the

chain drive. If the wear is considerable, replace it with new

one. Never fit a new chain on a worn sprocket, or a worn chain

on a new sprocket.

6.

Way of the cooling air

• The engine metal parts can burn your skin. Never touch the

cylinder, muffler or ignition plug etc. during operation or right

after stopping the engine.

• Before starting the engine, check around the muffler and

take off sawdust. If you do not, it will cause the overheating

and a fire. For preventing the trouble, please keep clean

around the muffler.

This engine is air-cooled. Dust clogging between the inlet port

of the cooling air and cylinder fins will cause overheating of the

engine. Periodically check and clean the cylinder fins in the

repair specialty store.

WARNING

WARNING

WARNING

WARNING

Before cleaning, the inspecting or repairing the unit, make sure

that engine has stopped and is cool. Disconnect the spark

plug to prevent accidental starting.

■ MAINTENANCE AFTER EACH USE

1. Air filter

Loosen the knob and remove the air cleaner cover. Take off the

filter elements and tap off attached sawdust. When they are

extremely dirty, shakewash with gasoline. Dry them completely

before reinstalling.

2. Oiling port

Dismount the guide bar and check the oiling port for clogging.

3. Guide bar

When the guide bar is dismounted, remove sawdust in the bar

groove and the oiling port.

Grease the nose sprocket from the feeding port on the tip of

the bar.

4. Others

Check for fuel leakage and loose fastenings and damage to

major parts, especially handle joints and guide bar mounting.

If any defects are found, make sure to have them repaired

before operating the saw again.

■ PERIODICAL SERVICE POINTS

1. Cylinder fins

Reriodically check and clean the cyliner fins in the repair spe-

cialty store.

2. Fuel filter

(a) Using a wire hook, take out the filter from the filler port.

(b) Wash the filter with gasoline.

Replace with new one if clogged with dirt completely.