Maintenance – Zenoah G240RC User Manual

Page 12

12

MAINTENANCE

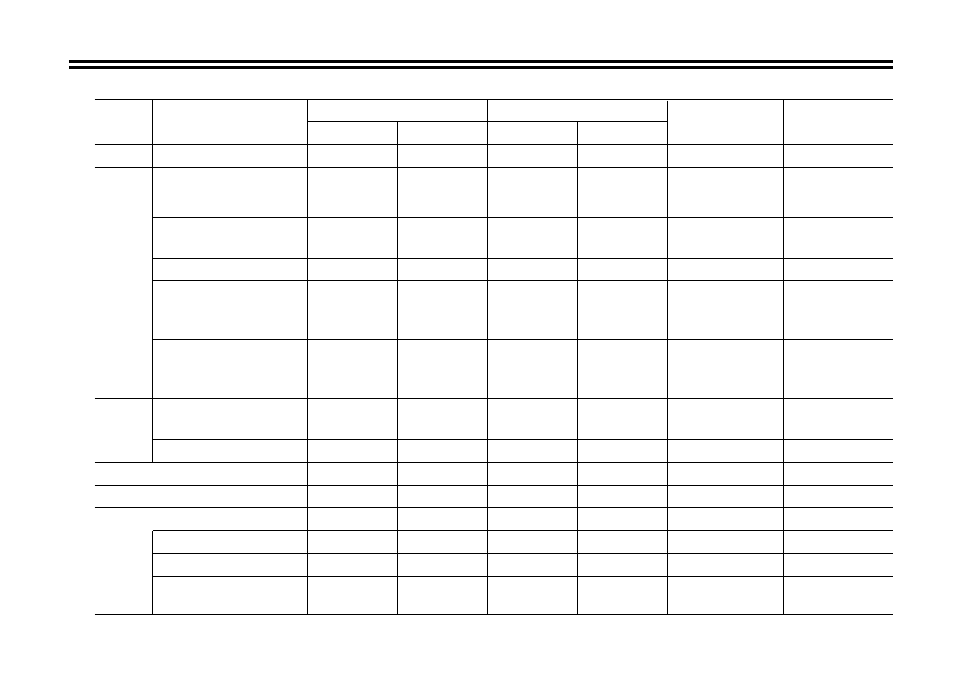

3) MAINTENANCE SPECIFICATIONS

G240RC

G270RC

Items

Standard

Limit

Standard

Limit

Measuring Device

Remarks

Bore (mm)

ø32

Plating damaged

ø34

Plating damaged

Eye Checking

Diameter (mm)

ш31.97

ш31.87

ш33.97

ш33.87

Micro Meter

Piston Ring

0.81

0.91

1.01

1.11

Thickness Gauge

Groove width (mm)

Piston Pin Hole (mm)

ш8.01

ш8.05

ш8.01

ш8.05

Cylinder Gauge

Clearance between

Piston and

0.03~0.06

0.15

0.03~0.06

0.15

Cylinder (mm)

Clearance between

Groove and

0.02~0.04

0.1

0.02~0.04

0.1

Thickness Gauge

Piston Ring (mm)

End Gap (mm)

0.05~0.25

0.5

0.05~0.25

0.5

Thickness Gauge

Width (mm)

0.78

0.73

0.98

0.93

Micro Meter

Piston Pin Diameter (mm)

ш8

ш7.98

ш8

ш7.98

Micro Meter

Connecting Rod Small end (mm)

ш11

ш11.05

ш11

ш11.05

Cylinder Gauge

Crankshaft Dia. at Main Bearing (mm)

ш12

ш11.98

ш12

ш11.98

Micro Meter

Eccentricity (mm)

—

0.07

—

0.07

Dial Gauge

Axial Play (mm)

—

0.5

—

0.5

Thickness Gauge

Gritty or

Gritty or

Main Bearing

—

—

—

Feels Flat Spot

Feels Flat Spot

At the skirt end and

the right angle to

the piston pin.

When inserted in

a new cylinder.

Piston

Cylinder

Piston

Ring

Micro Meter

Cylinder Gauge