Zanussi 200394 User Manual

N 900, Steam automatic pasta cookers, Zanussi

ZANUSSI

P R O F E S S I O N A L

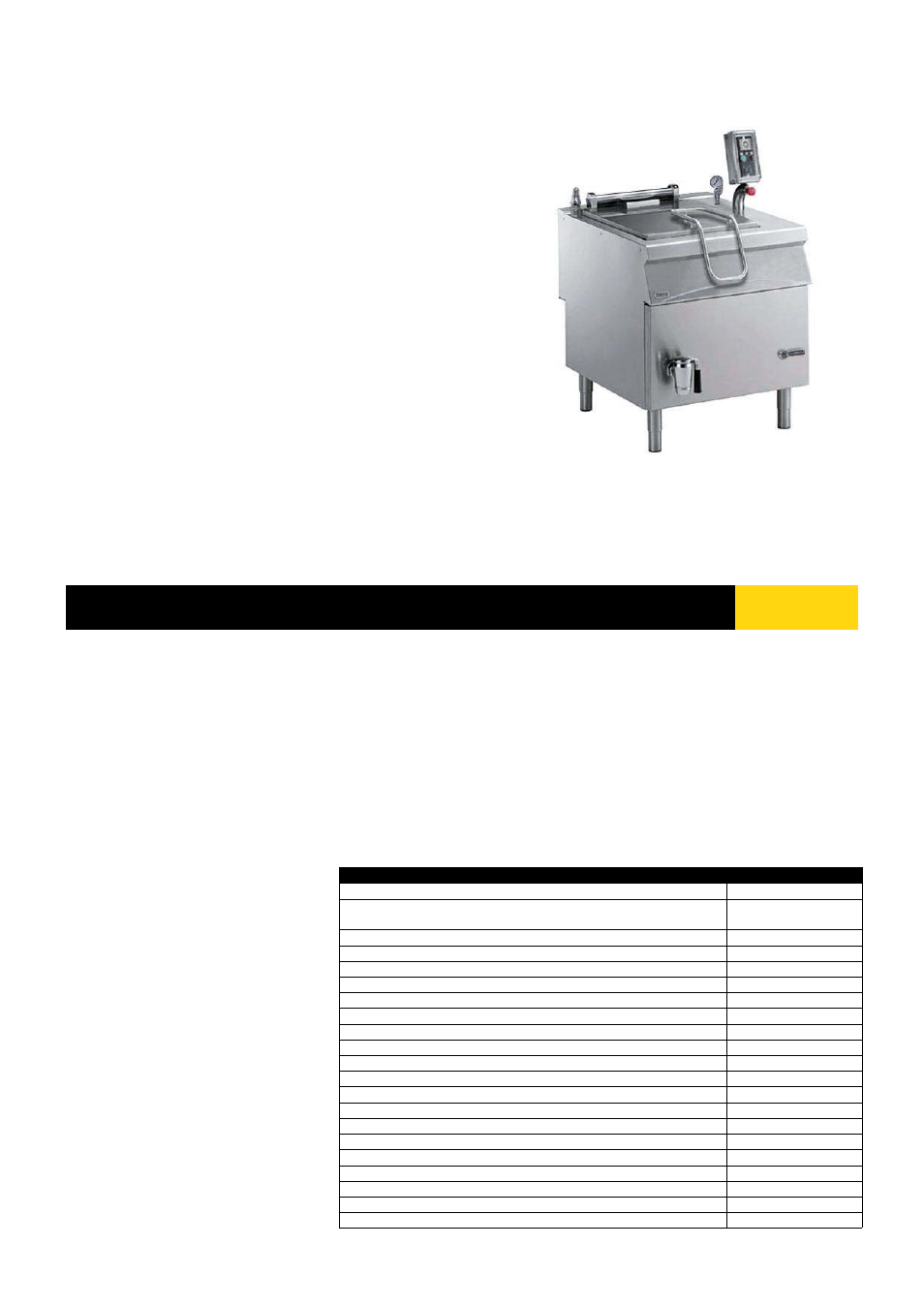

STEAM AUTOMATIC PASTA COOKERS

N 900

200394

Supply voltage

230 V, 1N, 50

Net weight - kg.

160

Control panel - V

24

installed-electric

0.3

Power - kW

Steam consumption at 0.5 bar - kg/h

50

Basket load capacity - kg

15

Number of baskets

1

height

550

depth

570

width

530

Usable well dimensions - mm

N° of wells

1

height adjustment

50

height

850

depth

900

width

800

External dimensions - mm

Power supply

Steam & Electric

NCPV800H

200394

CHARACTERISTICS

MODELS

TECHNICAL DATA

RANGE

COMPOSITION

N 900: a range of over 150 models for the

professional caterer designed to guarantee

the highest level of performance, reliability,

energy saving, safety standards and

ergonomic operation. These concepts are

reflected in the total modularity of the range

that ensures innumerable configurations,

either free-standing, bridged or cantilever.

N900 demonstrates how advanced

technology can satisfy the needs of the

professional caterer.

The model detailed on this sheet is a steam

automatic pasta cookers with one

automatically tilting basket, ideal for the

cooking in water of pasta, rice, minestrones,

boiled meat etc.

FUNCTIONAL AND

CONSTRUCTION

FEATURES

�

Load bearing frame in 304 AISI stainless

steel. Cooking well with rounded corners in

316 AISI stainless steel and fitted with an

overflow pipe. Jacketed well in 18/10

stainless steel.

�

Front and side panels in AISI 304

stainless steel.

�

Cooking basket and all other parts in

contact with water are made from 316 AISI

stainless steel.

�

Elevating basket which is automatically

tilted at the end of the cooking cycle by an

electromechanic linear activator fed at low

tension (24 V).

�

Electronic control end limit basket.

�

Automatic water filling and automatic

water topping up.

�

Automatic refilling of the evaporated water.

�

Digital timer guaranteeing precise settings

of cooking parameter.

�

Large drainage tap with insulated handle

positioned on the front of the appliance.

�

Insulated lid and handle in 304 AISI

stainless steel fitted on hinges with

counter-balancing springs.

Simple and functional control panel provided

with transparent plexiglass protection

�

Tilting lower panel or easily removed front

panels for quick and easy access to the

working parts.

�

Well fitted with overflow pipe to eliminate

foam.

�

Manometer to control steam pressure.

�

Steam supply pressure 0.5 bar.

�

Steam flow controlled by means of a ball

valve

�

Controls and safety unit consisting of

safety valve, depressurising valve and

pressure gauge.

�

A water condensing drainpipe for steam

appliances is compulsory .

�

The special design of the control knob

system protects against water infiltration.

�

All models can be installed on cantilever

system.

�

All models provided with service duct to

facilitate installation.

�

IPX5 water protection.