Lpg conversion – Westinghouse GHP17S User Manual

Page 12

CAUTION

This a

ppliance is fitted with Natural Gas burner injectors.

Please follow the procedure below if a conversion to suit

LP gas is required.

The conversion kit contains appropriate LPG injectors and

1 LPG sticker.

To convert to LPG

1. Remove the hotplate burners to access the hotplate

injectors. Replace the factory fitted NG injectors with

the appropriate injectors, as supplied (see Table 2).

2. Unscrew the hex nut from the regulator. The hex nut,

brass washer and nylon insert will disengage as

an assembly.

3. Unclip the nylon insert from the nut assembly

by rotating the insert ¼ turn, and pulling it free.

4. Turn over the insert, and clip back into position.

5. Refit the hex nut assembly to the regulator ensuring

that it is fully screwed down. The regulator is now

set for connection to LP.

6. Turn on the gas supply and at each new connection

check for leaks using soapy water: each hotplate

valve should be turned on, one at a time, and the

injector hole blanked off for several seconds.

7. The operation of the regulator can be confirmed by

connecting a manometer to the pressure test point

located on the side of the regulator body adjacent

to the outlet. With the appliance operating check

the outlet pressure

• when all burners of the appliance are operating

at maximum,

• when the smallest burner of the appliance

is operating at minimum.

Under these conditions the outlet pressure should not

vary from the nominal outlet pressure of 2.60kPa by

more than +/– 0.52kPa.

8. If the regulator appears to not be performing

satisfactorily then check the following points.

• If the outlet pressure is consistently too low then

the inlet pressure may be too low and adjustment

of an upstream regulator may be needed, or

an upstream regulator or valve with insufficient

flow capacity may be present in the gas supply

line. If this is suspected then it may be necessary

to repeat the checks whilst measuring both the

inlet and outlet pressure to determine if the inlet

pressure is in the range 2.75–7.00kPa.

• Check that the insert has been fitted correctly as

per diagram figure 10. Check that the hex nut is

fully screwed down.

• Check that the regulator has been fitted to the

gas supply line in the correct orientation, the arrow

on the base of the body indicates the direction of

gas flow.

Once these checks have been completed, if the

regulator still fails to perform in a satisfactory manner

it should be replaced.

9. One by one, turn the knobs to minimum and screw

in the bypass screw (accessible when the knob is

removed – refer figure 12) until a small stable flame

results. Turn the knob to maximum and then back to

minimum to ensure that the correct minimum flame

is maintained.

10. Attach the LPG sticker to the cooker, near the gas

supply inlet. Cover the Natural Gas label that is

factory fitted.

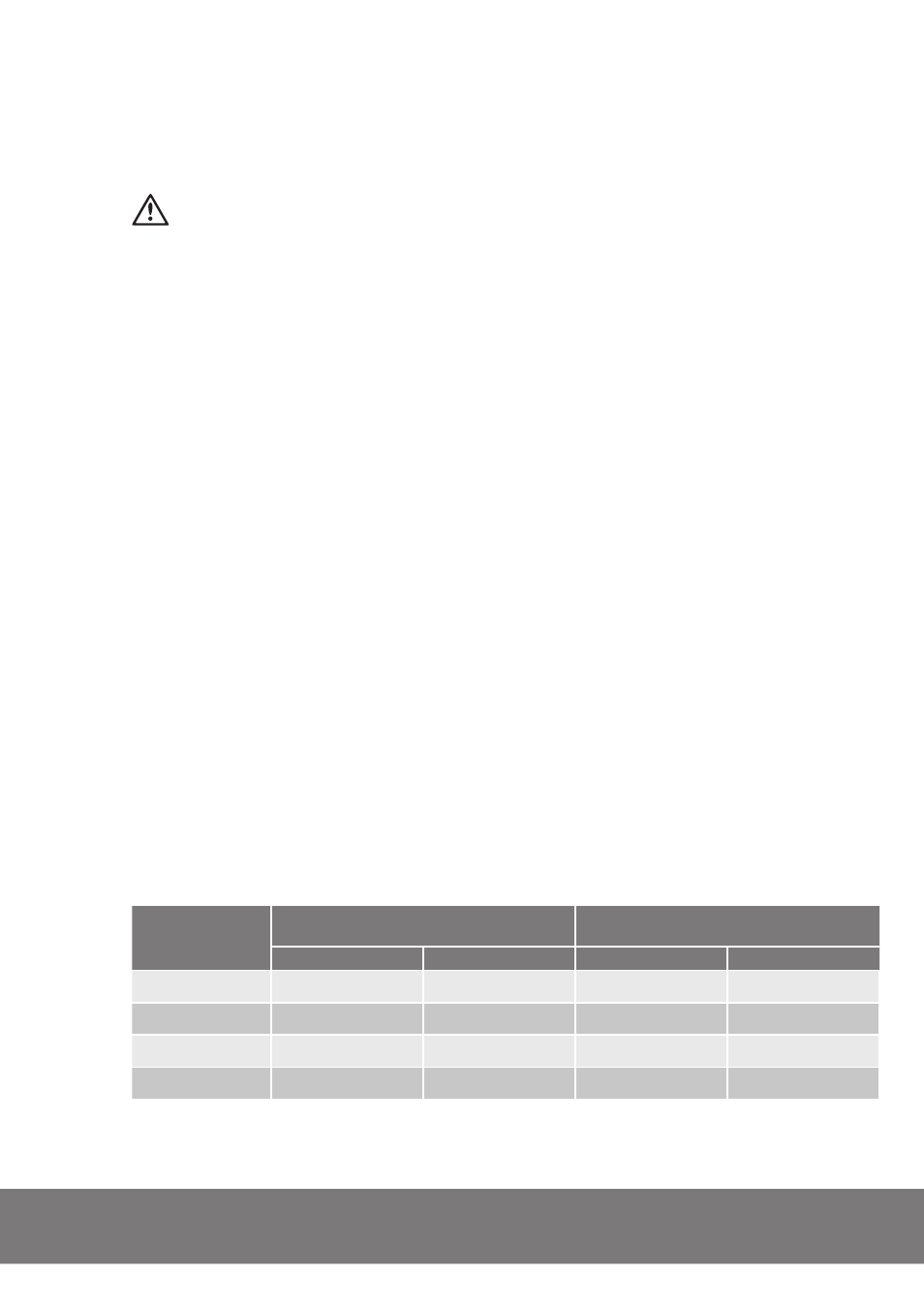

BURNER TYPE

NATURAL GAS

(Nominal test point pressure: 1.00kPa)

LPG

(Nominal test point pressure: 2.60kPa)

injector size (mm)

Gas consumption (MJ/h)

injector size (mm)

Gas consumption (MJ/h)

Small burner

1.00

5.1

0.55

4.2

Medium burner

1.35

9.0

0.70

6.5

Large burner

1.60

12.1

0.90

10.7

Wok burner

1.75

14.4

1.00

13.0

Table 2

LPG CONVERSiON