Worksaver ATVK-390 User Manual

Page 5

4

V E H I C L E P R E PA R AT I O N

The 12 volt electric seeder can be mounted on most all

terrain vehicles.

The ATV must have a 12 volt electrical system or you

need to supply a separate 12 volt battery to power the

spreader fan motor.

Be sure tires and rims are in good condition. Inflate tires

to the proper recommended air pressure.

PA C K I N G

Most ATV Broadcast Seeder-Spreaders are packaged

partially assembled in one carton consisting of: a basic

seeder unit, a scale plate with rod assembly, a mounting

frame and a mounting frame hardware kit.

A S S E M B LY & M O U N T I N G

Lower Mounting Bracket – Turn to the drawing that

shows the mounting bracket and parts required for your

particular make and model vehicle.

Assemble the parts as shown in the drawing. We

suggest keeping all bolts loose until all bolts are in place

– then tighten all clamps and bolts securely.

Seeder Mounting –

Slide the seeder/spreader unit

down over the up-right on the lower mounting bracket

and line up holes. Insert the

1

/

4

” x 2” hex head bolt and

fasten the two together securely.

Bolt the scale plate and control rod assembly on the

front left hand corner of the main seeder frame. Two

round head

1

/

4

” – 20 x

1

/

2

bolts are provided in the

hardware package for this. Place the end of the control

rod through the hole in the end of the seed gate control

plate (middle plate) and secure with the

3

/

32

” x

1

/

2

” cotter

pin provided.

NOTE: If the paint on the control rod does not allow the

button to slide on the control rod, it may be necessary to

sand some of the paint off with emery paper.

With the seed gate (middle plate) in the closed position,

place the scale plate lever in the closed position.

Retighten the adjustment bolt so that the adjustment but-

ton is tight on the control rod.

Move the lever and check to see that the seed gate

(middle plate) is moving with the lever.

Place the lever at the desired setting on the scale plate

and locate the stop bolt so that each time the lever is

pulled to the open position it will be at the same position.

Tighten the stop bolt.

Be sure your vehicle is in good condition and

properly equipped with counterweights if required.

Read all the safety precautions and make sure all

vehicle operators are familiar with the safety rules of

vehicle operation.

C A U T I O N !

I N S T R U C T I O N S

I N S T R U C T I O N S

(continued)

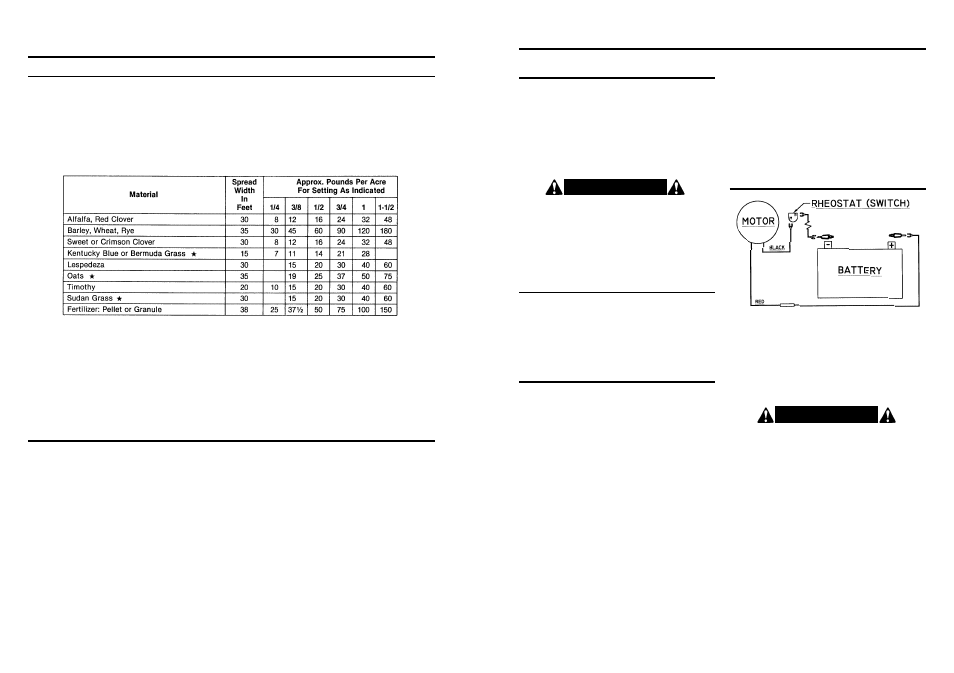

O P E R AT I O N A L S P R E A D I N G C H A RT

(Calibrated at 4 MPH ground speed)

.

Since there is no agitator in the seed hopper, these materials will bridge at narrow seed gate settings and

cause erratic seeding rates. If bridging occurs at wider seed gate settings, cleaning the seed or blending with

a small dense seed such as clover may help. A mix of dry sand with the seed (50/50 mix) can sometimes solve

the problem.

The spread width indicated on this chart is possible if spinner is operated 30 inches above the

ground. Seeder should be level or tilted forward slightly.

NOTE:

Spread Chart settings are approximate – always make trial run to check actual application rate.

The amount of seed or fertilizer broadcast depends on the size of the hopper opening and the speed of the vehicle.

The table shown is an approximate guide based on a forward speed of 4 MPH, so adjust for different speeds. A for-

ward speed of 8 mph will cut above rates by one half. A speed of 6 mph will change rates by 75%.

NOTE:

H E L P F U L T R O U B L E - S H O O T I N G T I P S

1. Not feeding even –

A. Seed gate opening may be set too close for the

material being spread. To overcome, set the open-

ing larger and driver faster to obtain same spread

rate.

B. Check material for foreign matter or lumps.

C. Set screw loose or missing on fan hub.

D. Too windy for material being spread.

E. Operator not spacing spread runs properly for

correct overlap.

For best results, cover area twice over at one-half

recommended material usage rate, the second

time over to run halfway between first spreading

width or in a criss-cross pattern. This method

allows the most complete and even coverage, as

well as to give operator a chance to adjust gate

setting to compensate for too thin or too heavy a

covering the first time over.

2. Poor spread –

A. Spreader fan speed too slow (under 520 rpm) will

result in a narrow spread.

B. Bent or broken fan blades.

7

W I R I N G

Refer to the electrical schematic above. Strip approxi-

mately 1/2” of insulation from the ends of the wires and

crimp on the terminals as shown. For best results, solder

the connections using electrical grade solder. Attach the

wires to the rheostat switch and battery as shown.

When properly connected, the fan should rotate in a

clockwise direction, looking down on the fan. The first

position on the rheostat switch is full speed, which will be

used for most seeding applications. The second position

is variable speed, which can be used to reduce the

spread width.

The fan motor is for use on 12 volt electrical systems.

The motor will draw approximately 3 amps full load.

Some vehicle manufactures offer electrical access plug

assemblies as a convenience for attaching auxiliary elec-

trical equipment. (Honda consent assemble D.C.

#31650-958-681).

To prevent polarity problems, run both wires to the

battery, rather than grounding through the chassis frame.

NOTE: Always disconnect negative (–) cable first and

connect it last.

Always stop engine before disconnecting or

connecting battery cables or servicing battery.

C A U T I O N !