Wachsmuth & Krogmann TAW-2030 User Manual

Page 17

16

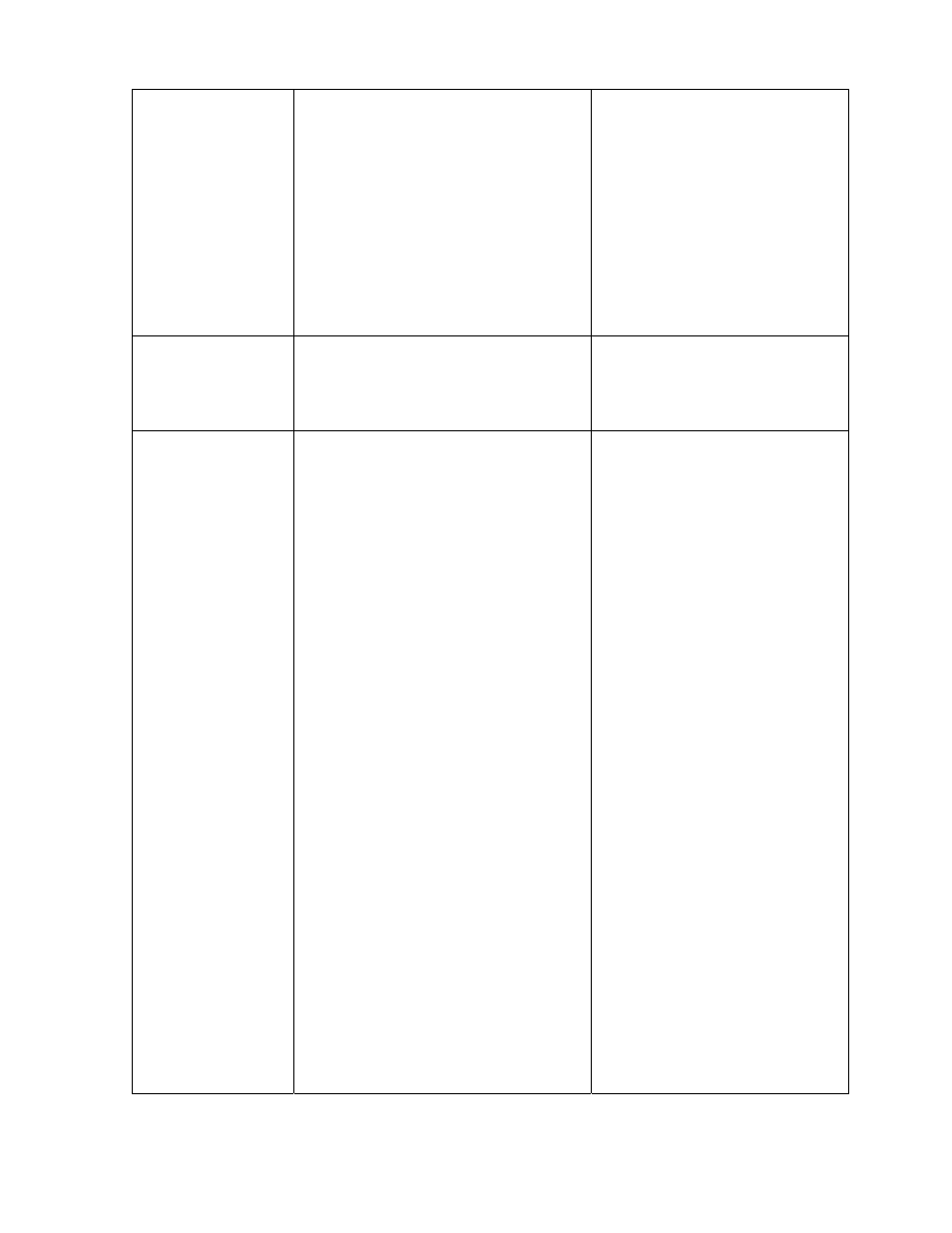

Air leaks in air

tank or

at air tank welds.

• Damaged air tank.

• DO NOT DRILL INTO,

WELD OR

OTHERWISE MODIFY

AIR TANK OR IT

WILL WEAKEN. THE

TANK CAN RUPTURE

OR EXPLODE. TANK

MUST BE REPLACED.

• Contact an authorized

qualified service

center.

Air leaks between

head and valve

plate.

• Leaking ring.

• Torque head screws to

8 ft. lbs. If this does

not stop leak, replace

ring.

Motor will not run

or restart.

• Tank pressure exceeds

pressure switch “cut-in”

pressure.

• Wrong gauge wire or length

of extension cord.

• Check valve stuck open.

• Loose electrical connections.

• Possible malfunctioning

motor or starting capacitor.

• Paint spray on internal

motor parts.

• Fuse blown, circuit breaker

tripped.

• Pressure release valve on

pressure switch has not

unloaded head pressure.

• Let motor cool off and

overload switch will

automatically reset.

• Motor will start

automatically when

tank pressure drops

below “cut-in” pressure

of pressure switch.

• Check for proper gauge

wire and cord length.

• Remove and clean, or

replace.

• Check wiring

connection inside

pressure switch and

terminal box area.

• Check fuse box for

blown fuse and

replace, if necessary.

Reset circuit breaker.

Do not use a fuse or

circuit breaker with

higher rating than that

specified for your

particular branch

circuit.

• Check for low voltage

• conditions and/or

proper extension cord.

• Disconnect the other

electrical appliances

from circuit or operate

the compressor on its

own branch circuit.