Troubleshooting chart – Whirlpool E2F65HD045V User Manual

Page 13

13

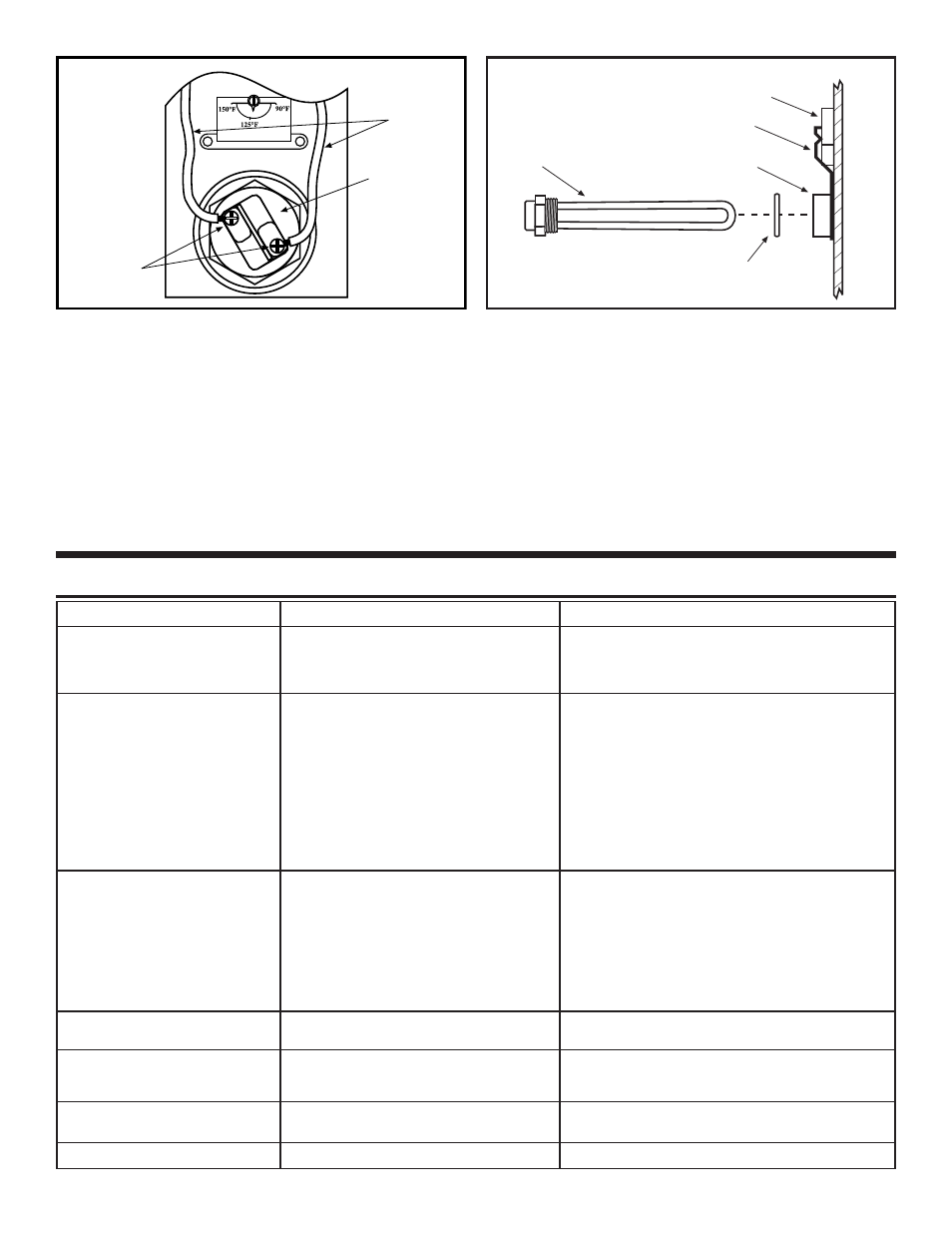

5. Clean the area where the gasket(s) fits to the tank. If

you are replacing the bottom element, remove the

accumulated sediment on the bottom of the tank.

6. Make sure the replacement element(s) has the correct

voltage and wattage rating by matching it to the rating

plate on the water heater. Position the new gasket(s)

on the element and insert it into the water heater

tank (Figure 14). Tighten the element by turning it

clockwise until secure.

7. Close the drain valve. Open the nearest hot water

faucet and allow the tank to fill completely with water.

Figure 14

Spud

Screw-in

Element

Gasket

Thermostat

Holding

Bracket

To purge the lines of any excess air and sediment,

keep the hot water faucet open for 3 minutes after a

constant flow of water is obtained.

8. Check for leaks around the element(s).

9. Reconnect the electrical wires to the element and

securely tighten the screws. Replace the plastic

thermostat cover making sure the attachment points

are engaged on the thermostat.

10. Replace the access cover(s).

11. Make certain the tank is filled with water. Applying

electric current to heater elements not submerged in

water will destroy them.

12. Reconnect electrical power to the water heater.

TROUBLESHOOTING CHART

PROBLEM

POSSIBLE CAUSE(S)

CORRECTIVE ACTION

NO HOT WATER

1. No power to heater

2. High Temperature Limit Switch open

3. Non-Functioning

upper

thermostat

1. Turn on electrical switch. Check for blown fuses

or tripped breaker

2. Reset. Check for source of trouble and correct

3. Replace

thermostat

INSUFFICIENT HOT WATER

1.

Non-Functioning

thermostats

2.

Non-Functioning

lower element

3. Improper

calibration

4. Thermostats set too low

5. Sediment or lime in tank

6. Heater too small for job

7. Wrong piping connections

8. Leaking

faucets

9. Wasted hot water

10. Long runs of exposed pipe

11. Hot water piping on outside wall

1. Replace

thermostats

2. Replace

element

3. Replace

thermostats

4. Set thermostats to desired temperature

5. Drain. Determine if water treatment is needed

6. Install adequate water heater

7. Correct

piping

8. Repair

faucets

9. Advise

customer

10. Insulate piping

11. Insulate piping

HIGH OPERATION COSTS

1. Improper

Calibration

2. Thermostats set too high

3. Sediment or lime in tank

4. Heater too small for job

5. Wrong piping connections

6. Leaking

faucets

7. Wasted hot water

8. Long runs of exposed piping

9. Hot water piping in exposed wall

1. Replace

thermostats

2. Set thermostat to desired setting

3. Drain. Flush-Provide water treatment if needed

4. Install

adequate

heater

5. Correct

piping

6. Repair

faucets

7. Advise

customer

8. Insulate

piping

9. Insulate

piping

SLOW HOT WATER

RECOVERY

1.

Non-Functioning

upper element

2. Non-Functioning lower element

1. Replace

element

2. Replace

element

DRIP FROM RELIEF VALVE

1. Excessive

water

pressure

2. Closed

system

1. Use Pressure Reducing Valve and Pressure

Relief Valve

2. See “Closed System/Thermal Expansion” section

THERMOSTAT DOES NOT

SHUT OFF

1.

Non-Functioning

thermostats

2. Improper

calibration

1. Replace

thermostats

2. Replace

thermostats

WATER ODOR

1. Sulfides in the water

1. See “Anode Rod/Water Odor” section

Figure 13

Screws

Wires

Element