Weed Eater 530087645 User Manual

Page 9

9

S

WHAT CAUSES BLADE THRUST Blade

Thrust can occur when the spinning blade

contacts an object that it does not cut. This

contact causes the blade to stop for an instant

and then suddenly move or “thrust” away

from the object that was hit. The “thrusting” re-

action can be violent enough to cause the op-

erator to be propelled in any direction and lose

control of the unit. The uncontrolled unit can

cause serious injury if the blade contacts the

operator or others.

S

WHEN BLADE THRUST OCCURS. Blade

thrust can occur without warning if the

blade snags, stalls, or binds. This is more

likely to occur in areas where it is difficult to

see the material being cut. By using the unit

properly, the occurrence of blade thrust will

be reduced and the operator will be less

likely to lose control.

S

Cut only grass, weeds, and woody brush up

to 2 inches in diameter with the brush blade.

Do not let the blade contact material it can-

not cut such as stumps, rocks, fences,

metal, etc., or clusters of hard, woody brush

having a diameter greater than 2 inches.

S

Keep the blade sharp. A dull blade is more

likely to snag and thrust.

S

Cut only at full throttle. The blade will have

maximum cutting power and is less likely to

bind or stall.

S

“Feed” the blade deliberately and not too

rapidly. The blade can thrust away if it is fed

too rapidly.

S

Cut only from your right to your left. Swing-

ing the unit in the same direction as the

blade spins increases the cutting action.

S

Use the shoulder strap and keep a firm grip

on the unit with both hands. A properly ad-

justed shoulder strap will support the

weight of the unit, freeing your arms and

hands to control and guide the cutting mo-

tion.

S

Keep feet comfortably spread apart and

braced for a possible sudden, rapid thrust of

unit. Do not overreach. Keep firm footing and

balance.

S

Keep blade below waist level; it will be eas-

ier to maintain control of unit.

S

Do not raise the engine above your waist as

the blade can come dangerously close to

your body.

S

Do not swing unit with such force that you

are in danger of losing your balance.

Bring the engine to cutting speed before en-

tering the material to be cut.

If the blade does not turn when you squeeze

the throttle trigger, make sure tube is fully in-

serted into the engine.

Always release the throttle trigger and allow

engine to return to idle speed when not cut-

ting. The blade should not turn while the en-

gine is running at idle. If the blade turns at idle,

do not use your unit. Refer to the Carburetor

adjustment section or contact your Autho-

rized Service Dealer.

Cut using the 8 o’clock

to 10 o’clock position of

the blade

10 o’clock

8 o’clock

WARNING:

The operator or others

must not try to clear away cut material with the

engine running or the blade turning to avoid

serious injury. Stop engine and blade before

removing materials wrapped around blade or

tube.

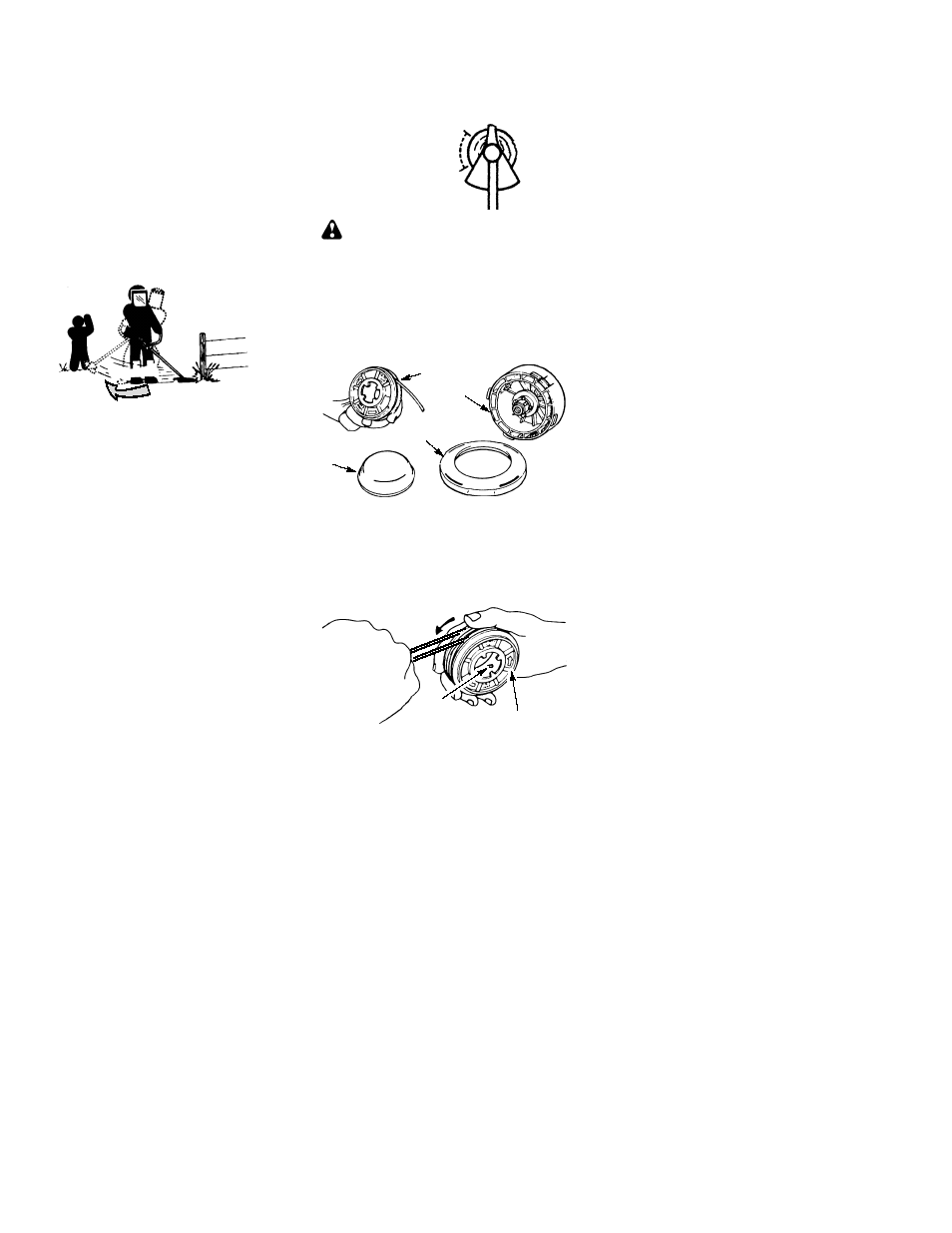

REPLACING THE LINE

S

Press the lock tabs and remove the cover.

S

Remove the lock ring, tap button, and

spool.

Spool

Hub

Lock Ring

Tap

Button

S

Check the indexing teeth on the spool and

hub for wear.

S

Use a clean cloth to wipe the inner/outer

surfaces of the spool and hub.

S

Use only .080 inch (2 mm) diameter line.

S

Cut two lengths of line approximately 20

feet (6 m).

S

Insert line into the small hole in the spool.

End of

Line

Arrow on

Spool

S

Wind the line evenly and tightly onto the

spool; wind in direction of arrow found on

spool.

S

Leave 4--6 inches (10--15 cm) of line un-

wound.

S

Insert line into the line exit hole in the hub.

S

Push spool into hub. Press spool down,

then turn it to catch spool tabs under gear

tabs.

S

Re-install the tap button, lock ring, and cov-

er.

S

Pull the end of the line to set spool in the op-

erating position.