Maintenance, Lubrication, Cleaning – Wilton 4210 User Manual

Page 11: Replacing the sanding belt, Replacing the sanding disc

11

Maintenance

This section provides procedures required to main-

tain the belt/disc sander. The numbers in parenthe-

ses throughout the manual correspond with reference

numbers for parts shown in the exploded views in the

Replacement Parts section.

Lubrication

The bearings used in the sanding machine are

sealed, pre-lubricated bearing. The bearings do not

require periodic lubrication.

Cleaning

Periodically use a vacuum cleaner to remove sanding

debris from the machine. In hard to reach areas,

brush the debris loose while vacuuming.

Replacing the Sanding Belt

WARNING: DISCONNECT ELECTRICAL POWER

TO THE MACHINE BEFORE PERFORMING ANY

MAINTENANCE.

1. Disconnect electrical power.

2. Position sanding belt platen (4) in the vertical

position. Remove eight screws (97) and guard

(96).

3. Remove screw (76) and guard (75).

4. Move tensioning lever (50) downward to slacken

sanding belt (79).

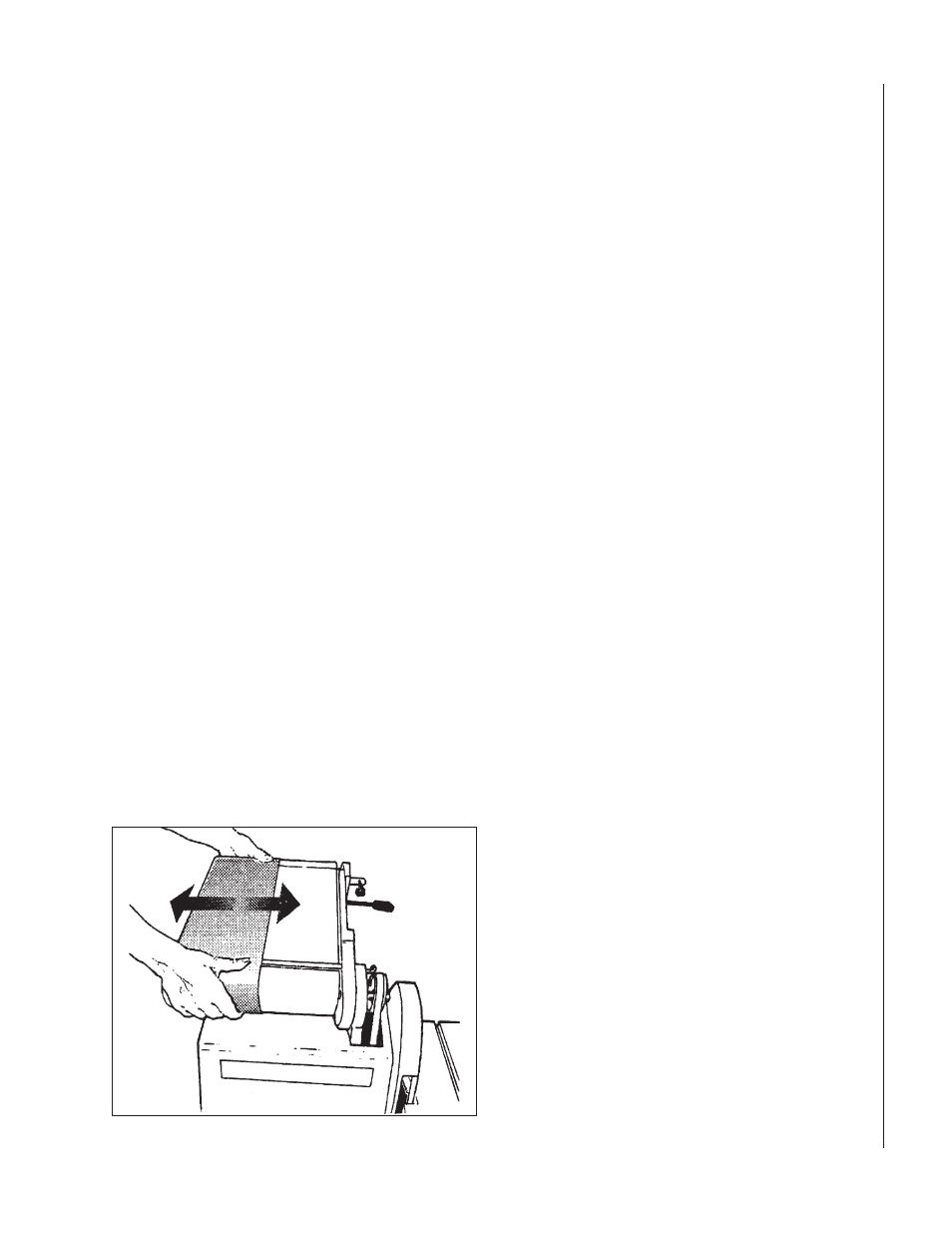

Refer to Figure 9. Slip sanding belt off drums (5) and

(39).

Figure 9. Replacing Sanding Belt

1. Install replacement sanding belt on drums.

Position edges of sanding belt evenly on the

drums.

2. Lift tensioning lever to tighten sanding belt on

drums.

3. Install guard (75) and secure with screw (76).

4. Install guard (96) and secure with eight screws

(97).

5. Connect electrical power and operate machine to

check operation.

6. If belt does not track properly, adjust tracking

(refer to Adjusting Belt Tracking).

Replacing the Sanding Disc

WARNING: DISCONNECT ELECTRICAL POWER

TO THE MACHINE BEFORE PERFORMING ANY

MAINTENANCE.

1. Disconnect electrical power.

2. Loosen screw (65). Remove disc table (60).

3. Remove four screws (56) and plate (55) from

disc shroud (53).

4. Insert a long T-handle Allen wrench through the

side opening in shroud (53) and into set screw

(57). Loosen disc set screw (57) and remove

disc (58).

WARNING: USE CARE WHEN USING KNIFE TO

SEPARATE SANDING DISC (59) FROM DISC (58).

INJURY FROM THE KNIFE MAY OCCUR IF THE

KNIFE SLIP OR IF SANDING DISC SHOULD

SUDDENLY COME FREE.

5. Using a knife, slowly work the tip of the knife

blade under sanding disc (59). Slowly work the

tip around the circumference of disc (58).

Continue to work around the circumference until

sanding disc can be separated by hand from

disc (58).

6. Remove paper backing from replacement sand-

ing disc (59). Place sanding disc (59) on disc

(58). Make sure the sanding disc is place evenly

at the outside diameter of disc (58).

7. Press on the sanding disc to remove any en-

trapped air and to make sure the sanding disc is

adhering to disc (58).

8. Install disc (58) onto shaft (16). Position the disc

on the shaft to provide clearance between plate

(55) and sanding disc. Tighten set screw (57).

NOTE: There is a close fit between the edge of disc

(58) and disc shroud. To ease installation and posi-

tioning of the disc, use an L-shaped tool (such as an

Allen wrench) under outer edge of the disc to support

and position the disc while tightening set screw.