Vermont Castings TP-250 User Manual

Page 3

3

19. Using a 7/16” nut driver, remove the threaded plug

from the test port.

20. Thread the supplied extension adaptor into the

open test port.

21. Attach a 1/4” diameter pressure gauge flexible hose

fully onto the barb of the adaptor.

22. Turn on gas supply and operate valve with remote

control as needed to indicate gas pressure. The

manifold pressure for LP should be approximately

10.0” wcp.

CAUTION: Turn off the valve and gas supply

before removing test port adaptor and replac-

ing plug.

23. After test, remove adaptor and replace plug.

24. Turn on gas supply and check that plugs are tight

and leak free.

25. Follow instructions in Homeowner’s Manual to

re-assemble brick panels, logs, lava rock, volcanic

rock, embers and andirons.

26. Replace glass frame.

27. Conversion complete.

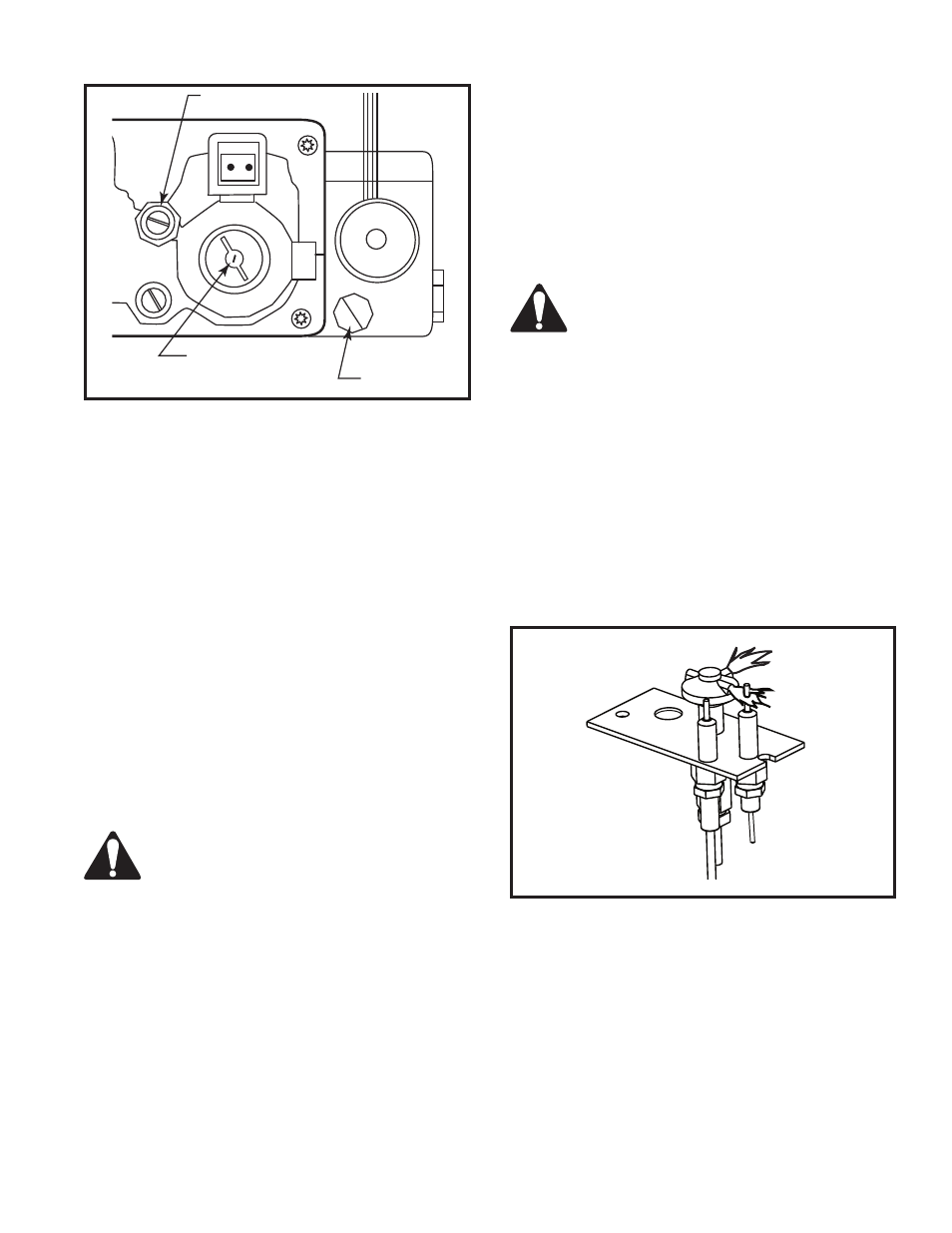

Pilot Flame Adjustment

Typically, the top 3/8” or 1/2” of the thermopile should

be engulfed in the pilot flame. (Fig. 8)

To adjust pilot burner: Adjust pilot screw on valve to

provide properly sized flame..

13. Reinstall burner to original position. Reinstall burner

leg, burner tube and fettle. Re-attach supply tube to

gas supply fitting. Using a back-up wrench, tighten

securely.

14. Test for leaks. Apply electric and gas to the system.

15. Light the pilot burner using the remote control. With

soapy solution check for leaks around the pilot as-

sembly where the tube enters the pilot assembly.

Tighten fitting if necessary.

16. Light the main burner and check for leaks around

the burner supply tube fittings and burner orifices.

Tighten if necessary.

17. Turn fireplace OFF.

18. After the conversion and leak checks have been

made, manifold outlet pressure can be checked

with a manometer at the test ports located at the

side front edge of the fireplace opening. The lower

test port is manifold outlet pressure.

CAUTION: Turn off the gas supply before

removing test port plug.

�����

�����������������������

����

�

��

�

��

��

��

Minimum Rate

Screw

CO137

Fig. 7 Remove black plastic cap and adjust rotary knob to

correct gas type. (LP position shown) Replace minimum rate

screw with one supplied in conversion kit.

Gas Type

Marker

Pilot Adjustment Screw

FP1229a

Pilot flames

4/03

FP1229a

Fig. 8 Correct pilot flame appearance.