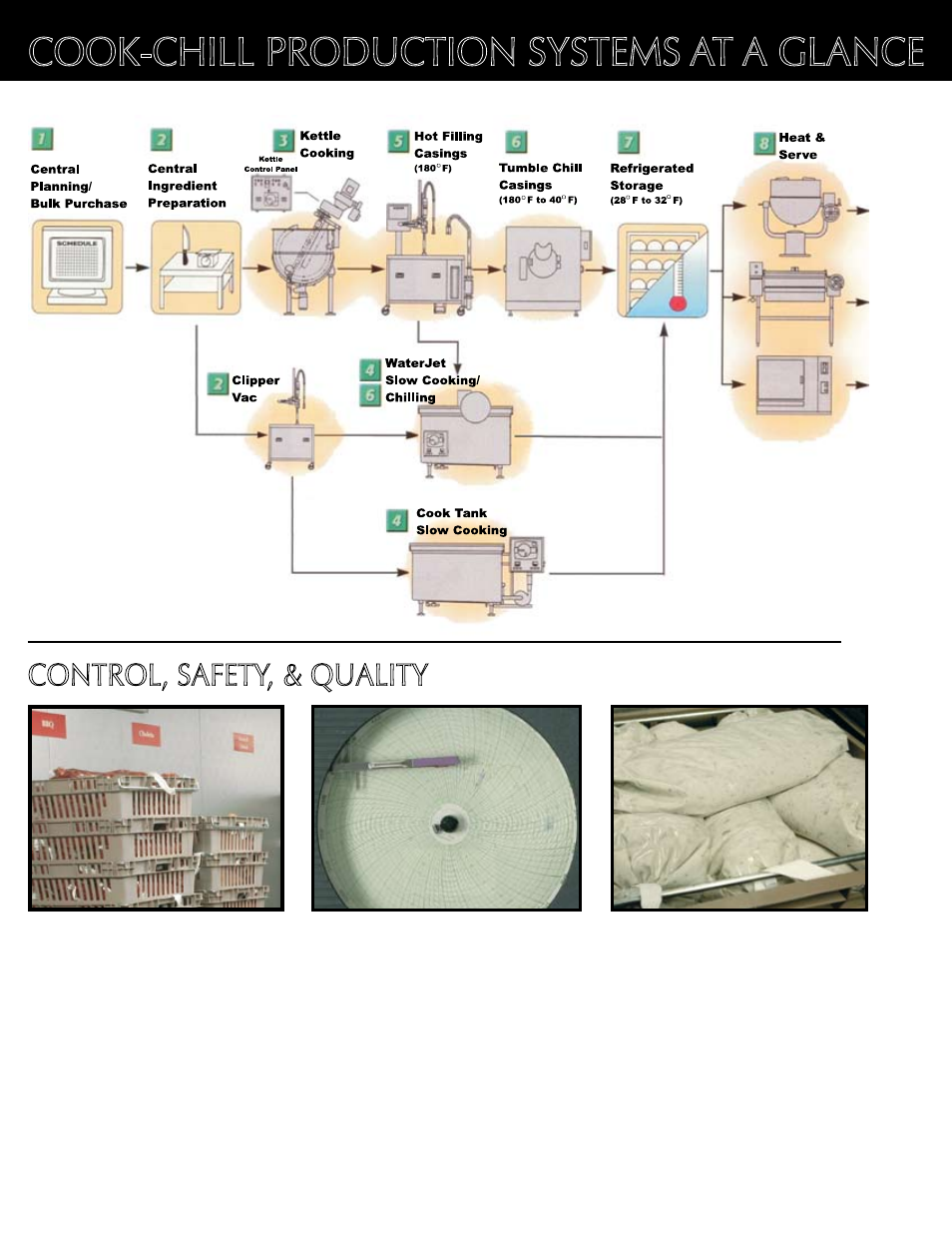

Cook-chill production systems at a glance, Control, safety, & quality – Unified Brands Cook-Chill Production Systems User Manual

Page 4

CONTROL, SAFETY, & QUALITY

Cased Product

Time/Temperature Chart

Refrigerated Food Bank

Sanitation & Food Safety

• Kettle and Cook Tank controls include

time/temperature chart recorders for

HACCP documentation.

• Ideal for HACCP food safety programs.

• Components are designed to the latest

sanitary standards.

• Products are packaged hot (sanitary).

• Durable, multi-ply, flexible plastic casings

allow product to be safely chilled, stored

and rethermalized.

Planning & Control

• A CapKold system allows advanced

scheduling of production, labor and

raw material purchase.

• Employees can be scheduled on an

eight-hour, five-day or a ten-hour,

four-day work schedule. Holidays and

vacations can be easily scheduled

around normal production.

• Output can typically be doubled or

tripled with little or no additional

equipment investment. CapKold offers

capacity for growth.

• A refrigerated food bank provides an

emergency back-up in case of natural

disaster or a work stoppage.

Food Quality

• CapKold food has the taste, texture, color

and aroma of freshly prepared items.

• Centralized purchasing, ingredient

preparation and production provides

consistent food quality and managed

recipe costs. Ingredients can be

purchased in volume.

• Large quantity automated cooking

ensures batch-to-batch consistency.

• Refrigerated – NOT FROZEN – storage

maintains cellular structure… key to

preserving texture and consistency.

• Cook Tank items slow cook in their

own natural juices - tenderizing

tougher cuts of meat, increasing yield

and enhancing flavor.

COOK-CHILL PRODUCTION SYSTEMS AT A GLANCE