Table 8 problems, causes and solutions, Table 7 table of programmed maintenance – Unigreen CAMPO 11 - 16 - 22 - 32 User Manual

Page 32

32 unigreen

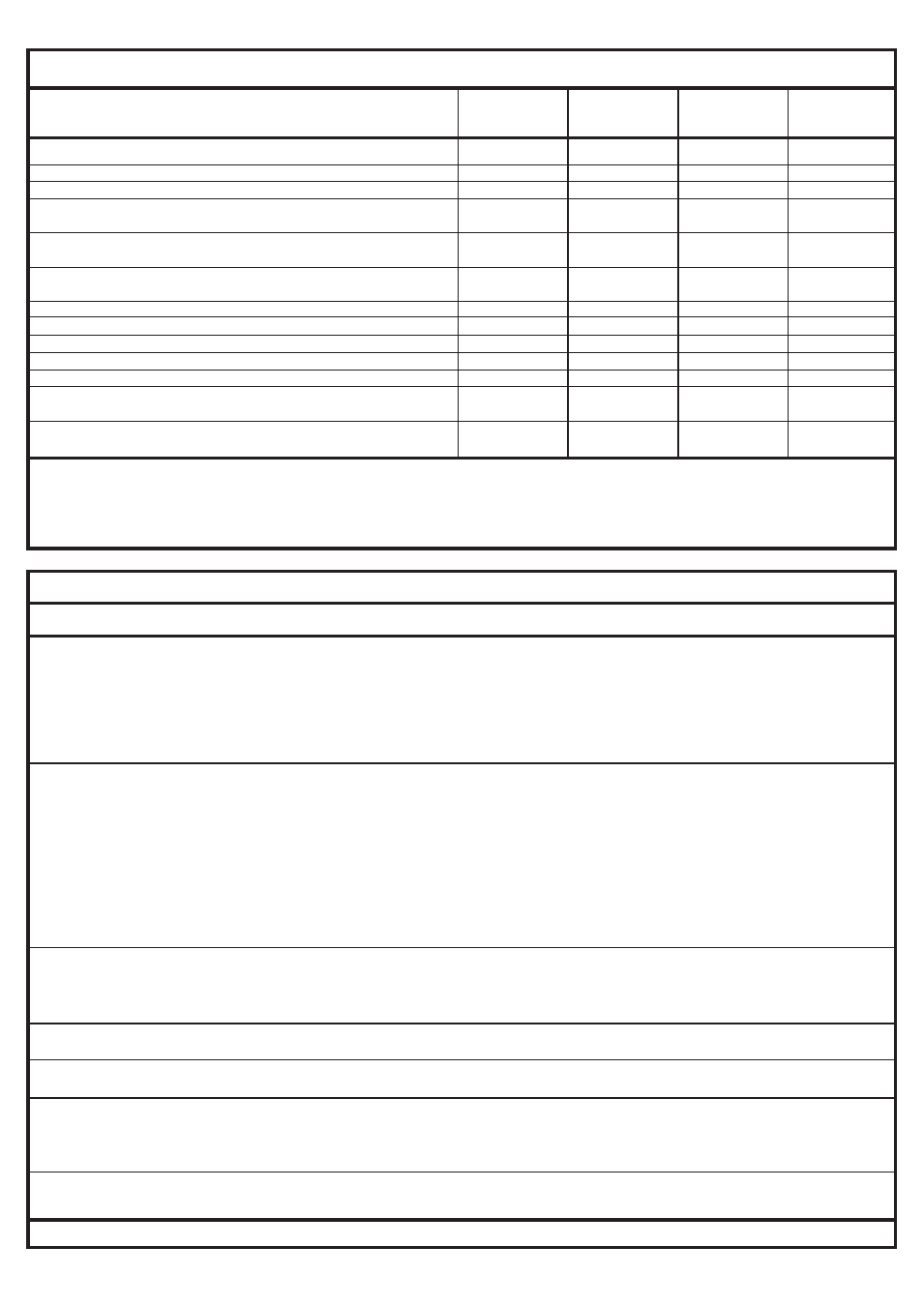

TABLE 7

TABLE OF PROGRAMMED MAINTENANCE

OPERATION

8 h

50 h

300 h

END

OF SEASON

Check the level and state of the oil

0

Check the accumulator pressure

0

Check the suction (hoses, pipes, unions)

0

Check and clean the suction

0

and delivery filters

Check the pump fixing feet

0

and screws in general

Check the diaphragm and the oil

X (1)

X (2)

and change if necessary

Check the suction/delivery valves

X

X

Check the pump screws and bolts are tight

X

Check and clean the nozzles and the non-drip diaphragm

0

Check the wear of the nozzles

0

Check the hydraulic oil level

0

Check any failures or cracking of the welds,

0

especially on herbicide booms

Grease the articulated joints and the wheel hubs

0

Check the tyre pressure

0

NOTE:

0 Operation to be carried out by the operator

X Operation to be carried out by a specialised technician or in an authorised workshop

(1) First oil change

(2) Change at the same time a changing the diaphragm

TABLE 8

PROBLEMS, CAUSES AND SOLUTIONS

PROBLEMS

CAUSES

SOLUTIONS

The pump won’t charge

Air suction

Check the suction system

Adjustment valve closed

Position the lever correctly

(Command group isn’t at

zero pressure)

Valves and/or valve seats

Replace or clean ( * )

suction and delivery worn

or dirty

The pump doesn’t reach the set

Valve and/or valve seat

Replace ( * )

pressure

adjustment worn

Valves and/or valve seats suction

Replace or clean ( * )

and delivery worn or dirty

Insufficient rpm

Bring speed up to correct rpm

always in the field of 350 ÷ 550 rpm.

The nozzles used are worn or have

Replace

holes that are too big

Suction blocked

Clean the cartridge of the

filter or remove the blockage

Irregular pressure (with impulses)

Valves and/or valve seats

Replace or clean ( * )

suction and delivery worn

or dirty

Air suction

Check the suction system

Excessive vibrations at delivery

Pressure accumulator discharged

Bring the air pressure back up to the right

or incorrect air pressure

value (see pump handbook) ( * )

Noisiness and the level of the oil

Blocked suction

Check the suction system

has dropped

Water in the oil

Breakage of one or more diaphragms

Replace ( * ) If the replacement isn’t

done immediately, drain the water out

of the pump and introduce clean oil

without water (also used) or diesel to

stop rust attacking the internalparts

No liquid comes out of the nozzles

Delivery filter dirty

Clean

Non-drip filters dirty

Nozzles blocked

NOTE: ( * ) Only specialised technician