Chimney connection, Operation of the stove – United States Stove Company 1864 User Manual

Page 5

1.

2.

3.

4.

5.

6.

7.

Crimped end of the pipe must be installed away from the heater.

The pipe must be hand formed to an oval shape which should

slide into the collar top. The pipe should be firmly attached to

the collar top with 3 screws and sealed with furnace cement.

Slope any horizontal pipe upward toward the chimney at least

1/4 " inch for each foot of horizontal run.

You must have at least 18" inches clearance between any

horizontal piping and the ceiling. (Fig. 2)

The pipe cannot extend into the chimney flue.(Fig. 4)

Seal each connector pipe joint with furnace cement. Also seal

the pipe at the chimney.

Use 3 sheet metal screws at each joint to make the piping rigid.

It is recommended that no more than two (2) 90 degree bends

be used in the stove pipe installation as more than two (2) may

decrease the amount of draw and possibly cause smoke

spillage.

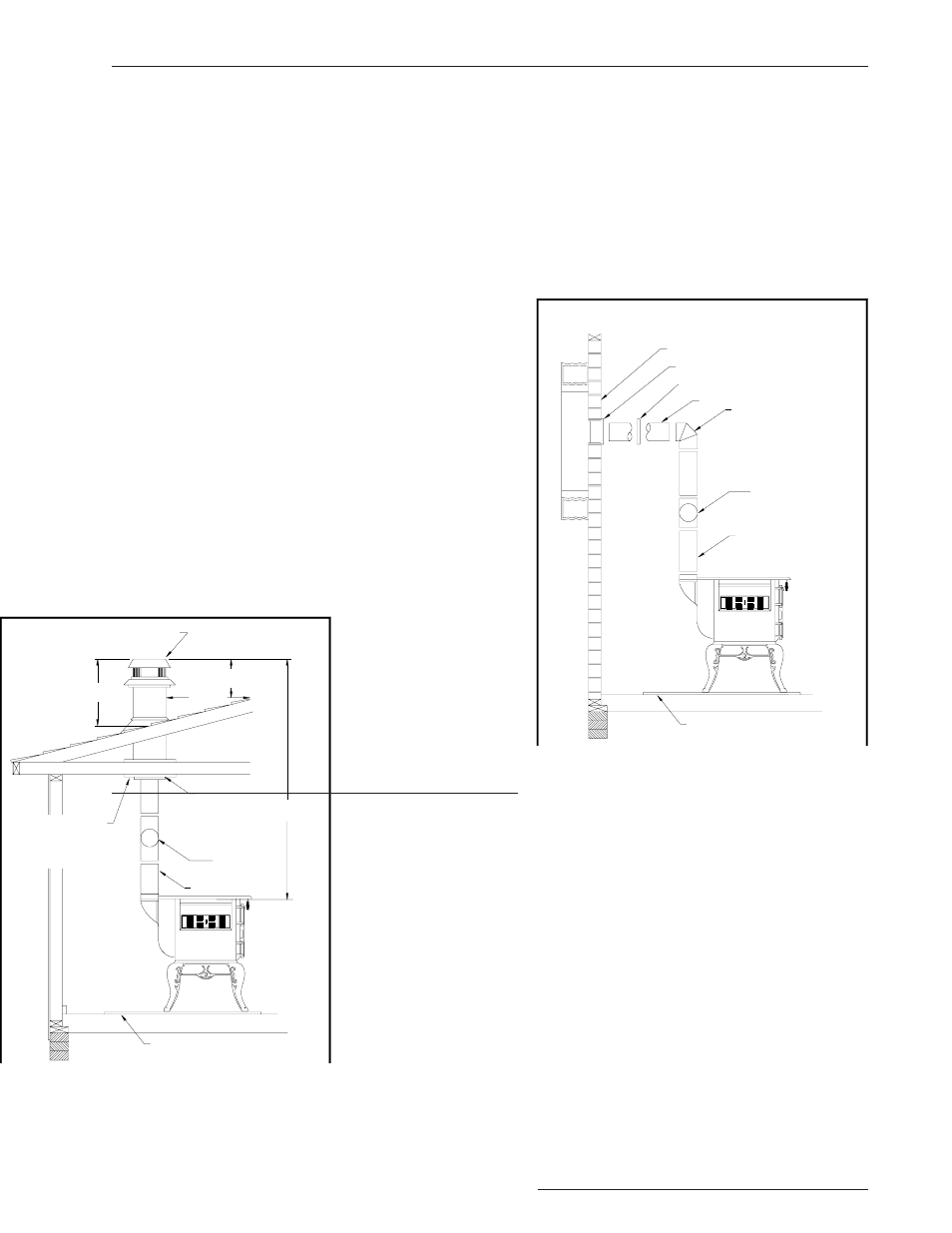

FLUE CONNECTION-NON-COMBUSTIBLE WALL

Chimney Connection

MASONRY CHIMNEY

The masonry chimney must comply with UL codes. Before using an existing masonry chimney, clean the chimney and inspect

the flue liner to be sure it is safe to use. Make repairs before attaching the heater. See Page 3, Item 5. Look at Fig. 5. The

connector pipe and fittings you will need to connect directly to a masonry chimney are shown. If the connector pipe must

go through a combustible wall before entering the masonry chimney, consult a qualified mason or chimney dealer. The

installation must conform to local fire codes, and NFPA 211. Do not connect this heater into the same chimney flue as the

fireplace or flue from another heater. The chimney used for a heater must not be used to ventilate the cellar or basement.

If there is a cleanout opening at the base of the chimney, close it tightly.

UL LISTED CHIMNEY

Carefully follow chimney manufacturer's instructions. Use only listed type HT per UL 103, 6-in diameter black or blued chimney

connector, minimum 24 gauge steel. If your chimney starts at the ceiling (Fig. 6), you will need enough 6" pipe to reach the ceiling.

The top of the chimney must be at least 3 feet above the roof and be at least 2 feet higher than any point of the roof within 10 feet.

(Fig 6)

RULES FOR CONNECTOR PIPE INSTALLATION

5

FLOOR PROTECTOR

FIG. 5

PIPE

BAROMETRIC

DRAFT REGULATOR

ELBOW

NON-COMBUSTIBLE WALL

THIMBLE

COLLAR

PIPE

CHIMNEY CAP MANDATORY

10 FT.

2 FT. MIN

3 FT. MIN.

11 FT. MINIMUM

NON-COMBUSTIBLE

CONSTRUCTION IN

ACCORDANCE WITH

NFPA 211

PIPE

PIPE REDUCER

FLOOR PROTECTOR

FIG. 6

BAROMETRIC

DRAFT REGULATOR

NOTE: The chimney connector shall not pass through an

attic, roof space, floor, ceiling, or similar concealed space.

Where passage through a wall or partition of combustible

construction is desired, the installation must conform with

NFPA 211.

Operation of the Stove

1.

Burn wood or coal only. The wood should be air dried

(seasoned) for at least 6 months after cutting. Build six (6)

small fires upon initial firing. Light wood or coal using paper,

twigs, etc.

2.

After the fire has been started and is burning satisfactorily,

adjust the rate of burning by opening or closing the draft control

on side of part.

3.

Never build extremely large fires in this type stove as damage

to the stove or smoking may result.

4.

If you have too much draft, then regulate the draft with a 6" cast

iron stove pipe damper properly installed in the first joint of the

stove pipe.

4.

DO NOT touch the stove after firing

7.

Never overfire this stove by building excessively hot fires as a

house/building fire may result.

8.

Inspect stove pipe every 90 days. Replace immediately if

stove pipe is rusting or leaking smoke into the room.

9.

This is a cast iron stove. It does not have welded seams. From

time to time you may have to "tune-up" the stove by refilling

and/or replacing the stove cement or mortar along the seams.

10. If stove begins to glow or turn red, you are overfiring.