Assembly, Warning – Troy-Bilt 42051 User Manual

Page 6

NOTE: Left and right sides of the unit are

determined from the operator position,

facing the direction of forward travel.

A. Inspect Unit

Inspect the unit and shipping crate for

damage immediately after delivery. Contact

the carrier (trucking company) if you find

or suspect damage. Inform them of the

damage and request instructions for filing

a claim. To protect your rights, put your

claim in writing and mail a copy to the car-

rier within 15 days after the unit has been

delivered. Contact the Factory if you need

assistance.

Tools/Materials Required for Assembly

(1) Scissors or knife (to cut plastic ties)

(1) *5/16" wrench

(1) *3/8" wrench

(2) *7/16" wrenches

(2) *1/2" wrenches

(1) *9/16" wrench

(1) Phillips head screwdriver (medium)

(1) Needle-nosed pliers (medium)

(1) Automotive-type tire pressure gauge

(1) Funnel

(1) Clean, high-quality motor oil. Refer to

the separate Engine Owner’s Manual

for the exact oil specifications and

amount needed for your engine.

* Adjustable wrenches may be used.

IMPORTANT: Motor oil must be added to

the engine crankcase before the engine is

started. Follow the instructions in this

Section.

B. Unpack Unit

Follow these steps to unpack your unit.

1. After removing cardboard carton, re-

move discharge chute (O, Figure 2-4)

assembly (with attached hardware

bag) from inside cardboard sleeve.

2. Cut plastic ties securing handlebar

ends to chassis and remove handle-

bars. Remove any protective wrapping

on handlebars.

3. Cut the four plastic ties (two on auger

shaft and two on wheel axle) that se-

cure the unit to the shipping pallet.

4. Move unit onto a clean, level surface.

The unit is heavy. To move the unit

off the shipping pallet, use caution

and obtain the help of at least one

assistant.

5. The hardware bag should contain the

following items:

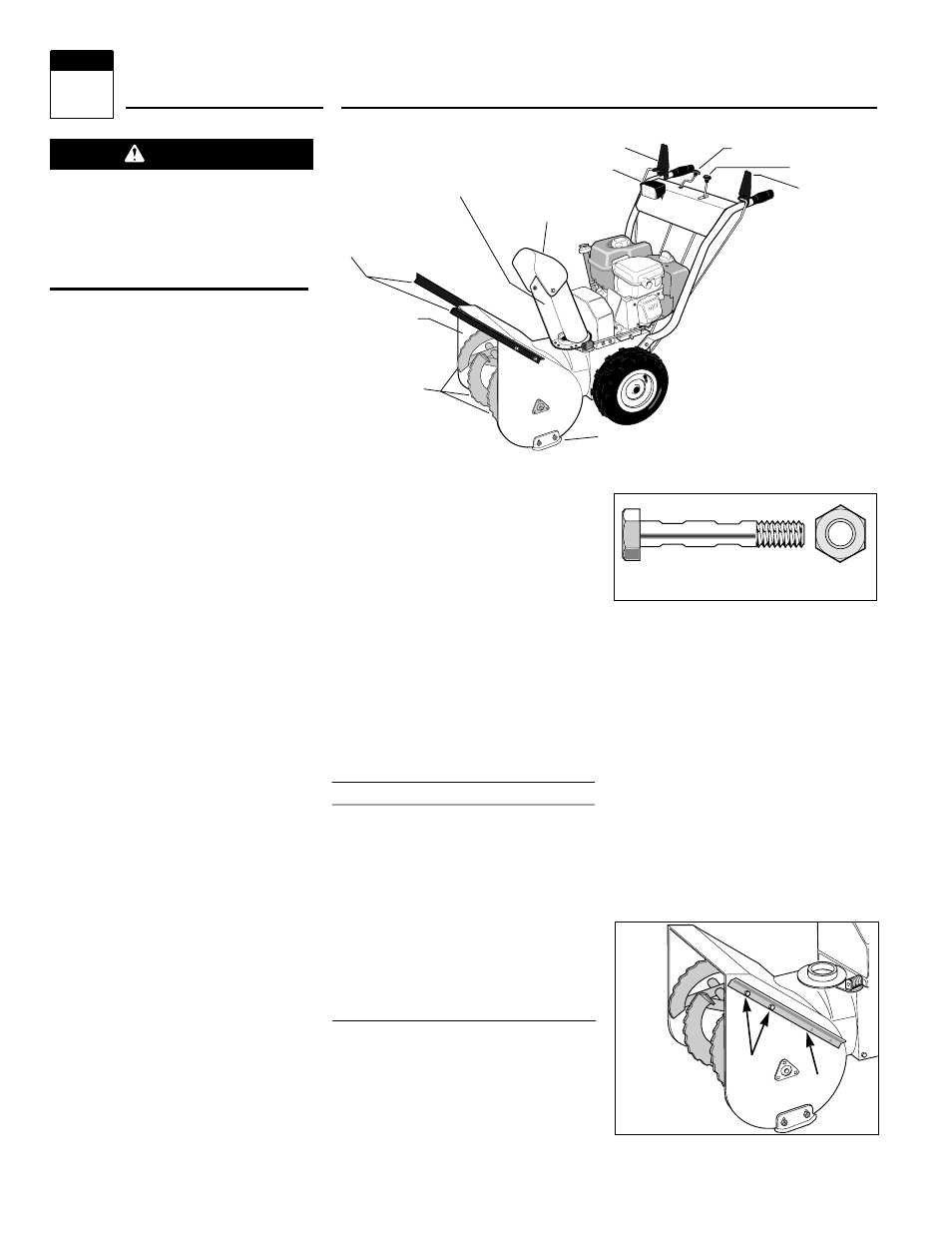

* These are replacement parts (Figure 2-1)

that should be kept with this manual (if the

auger jams, the shear bolts are designed

to break to prevent damage to the auger

drive). See Section 5 for replacement

information.

C. Remove Drift Slicers

(if equipped)

1. Remove the four screws (B, Figure

2-2) and locknuts (two on each side)

that secure the drift slicers (A) and re-

move them from both sides of the col-

lector (auger/impeller) housing.

NOTE: For shipping purposes, the drift

slicers are mounted backwards.

2. Place the drift slicers and hardware

aside. The drift slicers can be attached

after the unit is assembled (see last

step of these assembly instructions).

Description

Qty.

Engine Stop Switch Key .................... 1

Plastic Cable Tie ................................ 3

Hex Hd. Flange Screw, 3/8-16 x 3/4 .. 4

Hex Hd. Screw, 1/4-20 x 3/4.............. 2

Locknut, 1/4-20 ................................ 2

Phillips Hd. Screw, #10-24 x 3/8 ...... 2

Locknut, #10-24 ................................ 2

Cotter Pin .......................................... 1

Electric Start Power Cord .................. 1

*Shear Bolt, 5/16-18 x 1-3/4 ............ 2

*Locknut, 5/16-18 ............................ 2

To prevent personal injury or property

damage, do not start the engine until all

assembly steps are complete and you

have read and understand the safety and

operating instructions in this

manual.

WARNING

6

Assembly

2

Section

Figure 2-1

Figure 2-2

B

A

Drift Slicers

(Optional)

Discharge Chute

Chute

Deflector Cap

Auger Drive Control Lever

Light

Chute Directional Control

Wheel Drive

Control Lever

Auger Assembly

Skid Shoe

Collector

(auger/impeller)

Housing

Gear Shift Lever

FULLY ASSEMBLED UNIT