Maintenance – Tiger Products Co., Ltd RBF-12C User Manual

Page 84

Maintenance Section 5-2

MAINTENANCE

RBF-12C 07/04

© 2004 Alamo Group Inc.

LUBRICATION

Gearbox

The gearbox on the machine is filled with 10W/30 oil before it leaves the factory and should not need

topping-off, although it is recommended that the oil level is checked before the machine is used. Change

the oil after the first 200 hours of operation and thereafter every 1600 hours of operation.

Grease Points

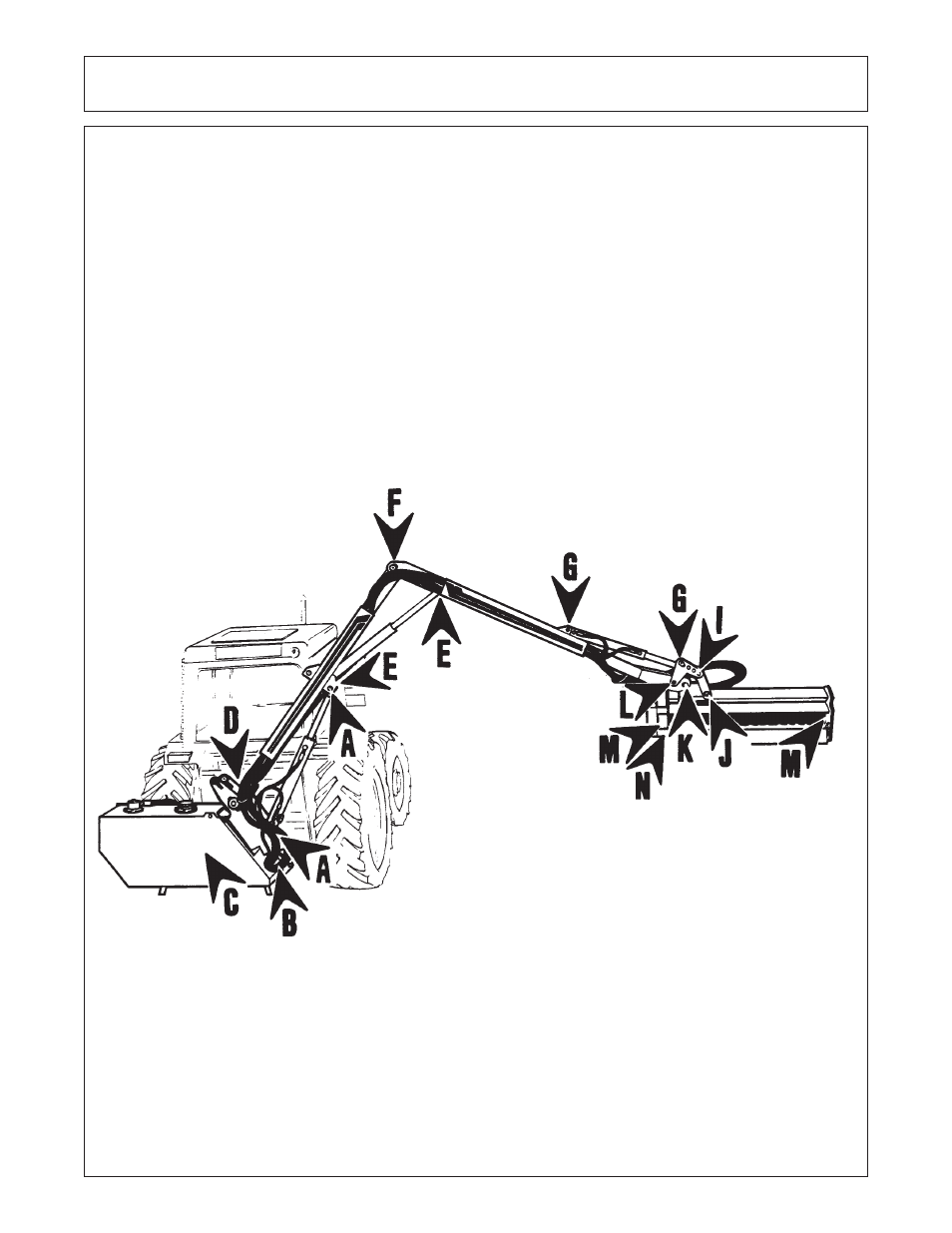

All grease points shown in FIGURE 5-1 below should be greased before operating the machine. To make

greasing easier by relieving the weight form the pivot pins, rest the rotor unit on the ground, stop tractor

engine and operate control levers in both directions. Grease daily or every 8 hours of operation. Use a

high quality lithium base #2 grease.

PTO Drive Tubes

Grease PTO square tubes before operating machine. Grease the PTO bearings every 8 hours of operation

FIGURE 5-1

A. 1st Ram Pivots

2 Fittings

B. Breakout Ram Pivot

2 Fittings

C. P.T.O. Shaft

2 Fittings

D. 1st Arm Pivot (Base)

1 Fitting

E. 2nd Ram Pivots

2 Fittings

F. 1st and 2nd Arm Pivot

2 Fittings

G. 3rd Ram Pivots

2 Fittings

H. Rotor Link / Ram Pivot

2 Fittings

I.

Rotor Link Pivot

1 Fitting

L.

Rotor Unit Pivot

1 Fitting

M. Rotor Shaft Bearing

1 Fittings

Total

20 Fittings

*NOTE:

Lubricate flail roller bearing until lubricant

can be seen coming out between

roller and bearing housing.