Warning – Troy-Bilt 665B User Manual

Page 10

10

Section 3: Features and Controls

Moving the lever up increases the tilling

depth. The lowest notch allows a tilling

depth of approximately six to eight inches,

depending on soil conditions.

For best results, always begin tilling at a

very shallow depth setting and gradually

increase the tilling depth.

Complete details on using the Depth Reg-

ulator are found in Section 4 of this

manual.

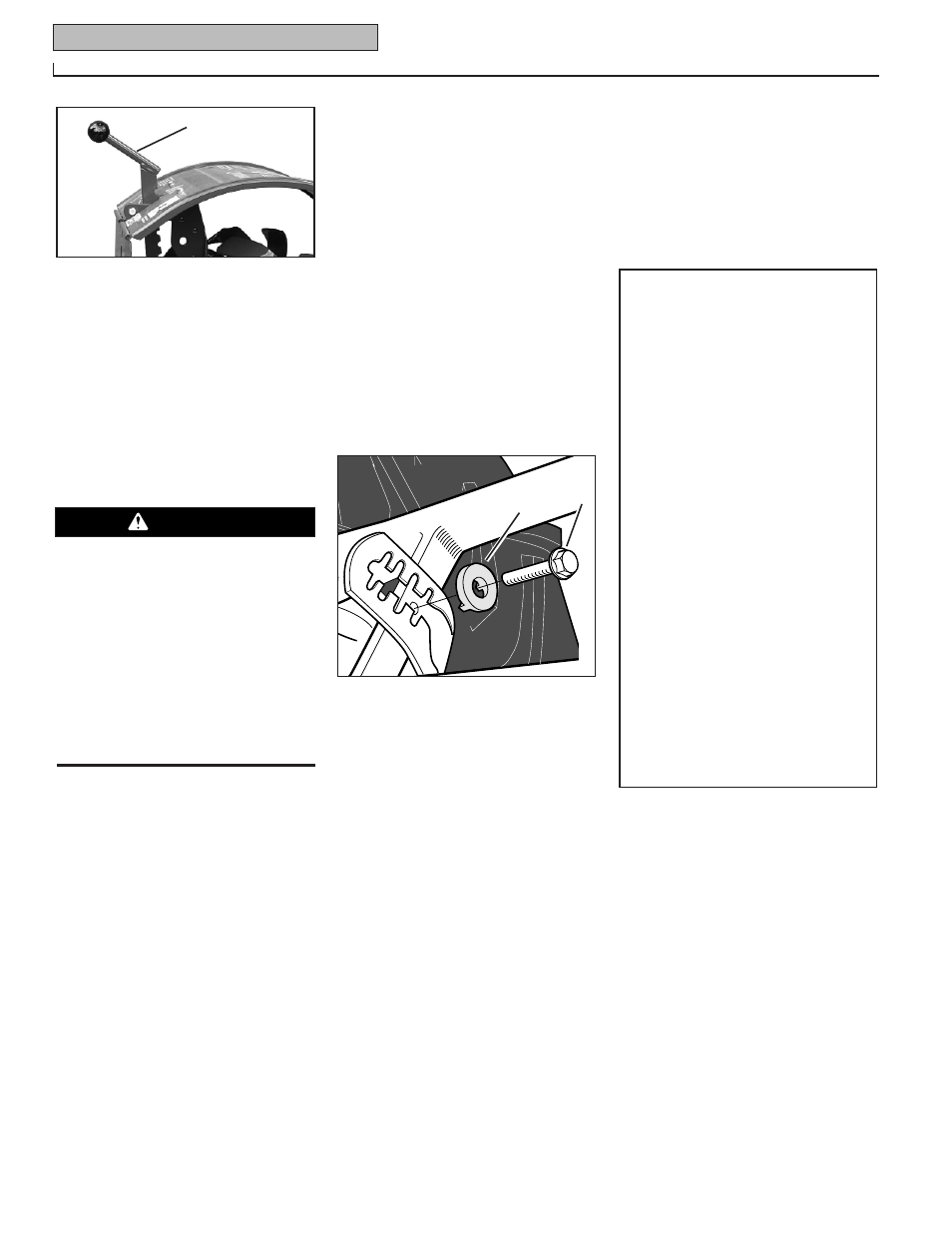

HANDLEBAR HEIGHT ADJUSTMENT

The handlebar height is adjustable to four

different settings. When setting the

height, keep in mind that the handlebars

will be lower when the tines are engaged

in the soil.

To Adjust the Handlebar Height:

1. Stop the engine, wait for all parts to

stop moving and then disconnect the

spark plug wire. Remove the ignition key

on electric start models.

2. Loosen the two screws at the lower

ends of the handlebar.

3. Loosen the height adjustment flange

screw (F, Figure 3-3) and pull the keyed

washer (E) free of the slots in the curved

height adjustment bracket.

4. Move the handlebars to the new slot

setting and insert the raised keys on the

keyed washer into the slot. Tighten the

height adjustment flange screw securely.

5. Retighten the two screws at the ends

of the handlebar.

ENGINE CONTROLS

Refer to the engine manufacturer’s Engine

Owner’s Manual (included in the tiller liter-

ature package) to identify the controls on

your engine.

IMPORTANT: The control for stopping the

engine is located on the engine.

Figure 3-3

E

F

• Do not attempt to till too deeply too

quickly. Gradually work down to

deeper tilling depths.

• Place the Depth Regulator Lever in the

“travel” position before starting the

engine. This position prevents the

tines from touching the ground until

you are ready to begin tilling.

Failure to follow this warning could

result in personal injury or property

damage.

WARNING

Figure 3-2: Depth Regulator Lever.

D

SPECIAL NOTICE REGARDING

“MOTOR OIL ALERT SYSTEM”

The engine on your tiller is not

equipped with a functioning “Oil Alert

System” and you should ignore any

references in your Engine Owner’s

Manual regarding this feature.

The “Oil Alert System” is not practi-

cal for use with your tiller because

the engine is frequently operated in

non-level applications that would

provide false readings to the

system’s oil level sensor. These

false readings would result in fre-

quent, and unnecessary, engine shut

downs.

You can easily protect your engine

from damage caused by insufficient

oil in the crankcase by simply

remembering to do the following:

• Check the motor oil level before

starting the engine.

• Check the motor oil level after every

five (5) hours of continuous

operation.