Caution, Maintenance – Ohlins CANNONDALE FG 9910 User Manual

Page 6

6

CAUTION!

Adjust the oil level with the fork leg

fully compressed and no preload

washer nor spring installed.

NOTE!

See mounting instruction for

recommended oil level.

The oil level is measured from the

top of the outer leg, with the top nut

off, see fig 6.

A change in oil level should be

made in small steps. We recommend

a change of 5 mm at a time and not

outside the range of 80-130 mm.

Maintenance

Telescopic front forks depend on a

smooth, friction free action.

Make sure your forks are regularly

serviced.

Do not use strong solvents, such

as brake cleaner, to clean the front

forks. This will dry out the seals and

the steel tubes and cause friction or

leakage.

After every race:

Clean externally and spray with an

all-purpose oil after washing with

detergent.

Check externally for damage.

Put a little Öhlins green grease

(148-01) on the steel tubes and

work it in by pushing the fork up

and down.

Every 20 hours:

Dismantle the fork and check all

parts for wear and damage, replace

if necessary, see page 10.

Both the adjusters have a normal

right-hand thread.

Click position zero (0) is when the

adjusters are turned

clockwise to fully

closed.

The adjustment range, from fully

closed until maximum open valve

(anticlockwise), is 20 clicks.

In order not to click in the wrong

direction; always first close the ad-

juster, then dial-in the new setting.

Making adjustments

To make improvements using the

adjusters, it is important to understand

the function of the front fork and the

shock absorber and through testing

learn how they effect the handling of

your bike.

Make sure that you have the correct

springs and the correct spring preload

before making any adjustments. And

always start with the Öhlins recom-

mended settings:

NOTE!

See mounting instruction for

recommended settings.

NOTE!

Higher click numbers give less damp-

ing force.

When making adjustments; keep

notes, make adjustments one at a

time... and in small steps.

The adjusters should normally not

be adjusted in steps of more than 2

clicks at a time and not outside the

usable click range.

When you think you have made an

improvement, go back to what you

started with and double check to be

sure. Pay attention to changes in

conditions like tires, temperatures

etc.

In general, compression damping

changes should be used to influence

the bike’s stability and response,

while rebound damping changes

should be used to influence comfort

and traction.

When you need more damping

force, you should mainly try to in-

crease compression damping and

use as little rebound damping as pos-

sible.

This usually means that you gain

comfort and performance in handling.

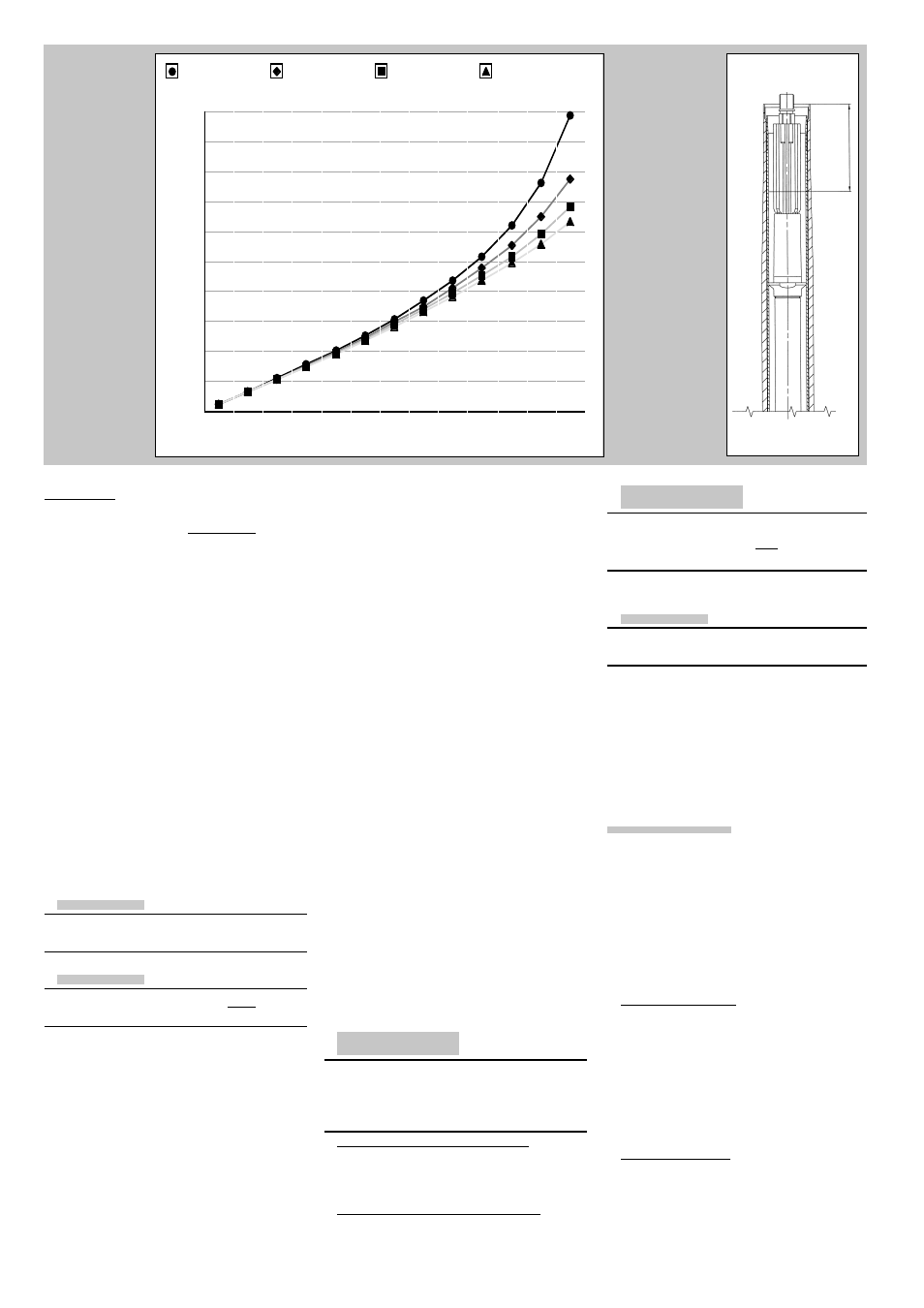

Oil level adjustment

As the air trapped between the oil

and the top nut acts as an air-spring,

a change in oil level will effect the

damping forces. Not in the early

stage of fork travel, but a great deal

in the later stage.

A general description of how the oil

level/air-spring effects the damping

forces are shown in fig 5.

The air-spring gives the Öhlins

USD fork a progressive spring rate,

preventing it from bottoming out hard.

By using different combinations of

springs and oil levels/air-springs you

can alter the characteristic of the fork

and tailor it to suit different tracks and

conditions.

CAUTION!

The oil level must be the same in

both front fork legs.

Riding a bike with different oil levels

will cause instability.

When the oil level is raised:

The air-spring in the later half of

travel is strong, and thus the front

fork hard.

When the oil level is lowered:

The air-spring in the later half stage

of travel is soft, and thus the front

fork soft.

Oil level

6.

Oil level is

measured from

the top of the

outer leg, with

the top nut of,

the fork fully

compressed

and no preload

washer nor

spring installed.

Air spring

5.

A change in oil

level will effect

the damping

forces, not in the

early stage of

fork travel but a

great deal in the

later stage.

Oil level

5 0 0

4 5 0

4 0 0

3 5 0

3 0 0

2 5 0

2 0 0

1 5 0

1 0 0

5 0

0

F

o

r

c

e

k

g

f

Stroke mm

0

2 0

4 0

6 0

8 0

1 0 0

1 2 0

Oil level 100 mm

Oil level 110 mm

Oil level 120 mm

Oil level 130 mm

Force

Stroke