Do you cut wood in dirty or abrasive conditions, Chain replacement parts, Maintenance tools – Oregon Super Guard 72LGX User Manual

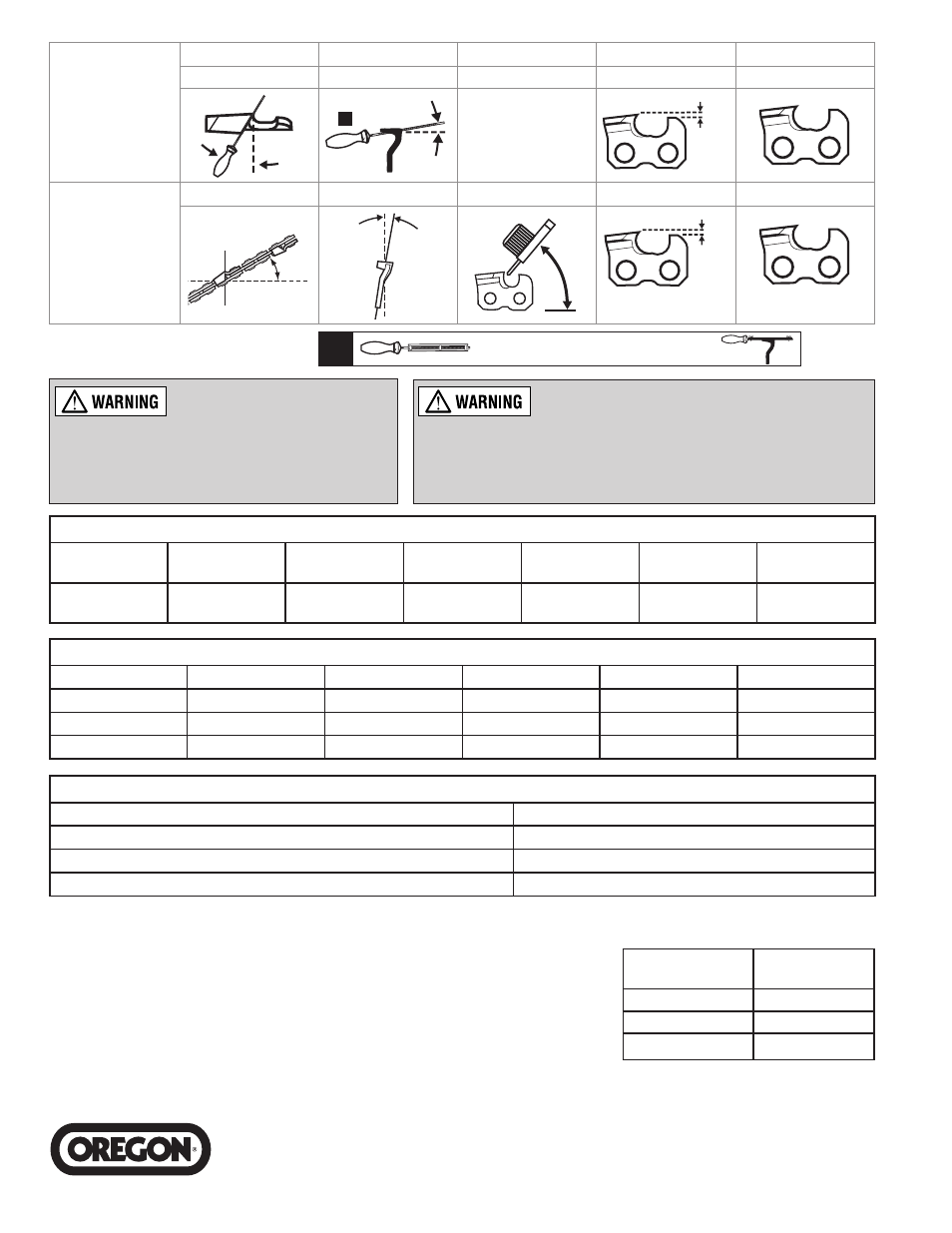

Page 2: Which cutter sequence is best, standard or skip, Filing instructions, Grinding instructions

For more information on these and other OREGON

®

products, contact your authorized OREGON

®

distributor, or:

OREGON

®

| BLOUNT, INC. PO Box 22127 · Portland, OR, U.S.A. 97269-2127

Phone: 503-653-8881 Fax: 503-653-4201 Web: www.oregonchain.com

IN CANADA: OREGON

®

DISTRIBUTION LTD. 505 Edinburgh Rd. N., Guelph, Ontario, Canada N1H 6L4

Phone: 519-822-6870 Fax: 519-822-4999

Printed in USA 72LGX F&B A107022 AG 1108

OREGON

®

72LGX/JGX, 73LGX/JGX, and 75LGX/JGX Super

Guard

®

chains may be capable of kickback that could result in

serious injury to the saw operator or bystanders.

Although these chains have features designed to reduce kickback energies, these

are NOT low-kickback chains. Do not use OREGON

®

72LGX/JGX, 73LGX/JGX, or

75LGX/JGX Super Guard

®

chains unless you have experience and specialized training

for dealing with kickback. Saw chain with lower kickback potential is available.

Failure to follow filing instructions can

increase the level of kickback which

can result in severe injury to the saw operator or bystanders.

*

Do not exceed the depth-gauge setting shown above

*

Always file depth gauges back to their original rounded

or ramped shape after lowering

If you cut abrasive woods such as railroad ties, skidded wood, fire damaged areas, par-

tially logged areas after a skidder, or any place where wood is dirty, we recommend you

use the MultiCut™ versions of OREGON

®

chains. MultiCut™ chains have extra-heavy-

duty chrome plating applied with an advanced plating process to withstand these kinds of

tough, dirty conditions. It also allows you to maintain your saw chain without the need of

any special tools. Contact OREGON

®

or your authorized OREGON

®

distributor for further

information on MultiCut™ chains.

Do you cut wood in dirty or abrasive conditions?

Standard

Chain Part No.

Multicut

Part No.

72LGX

M72LPX

73LGX

M73LPX

75LGX

M75LPX

Chain Replacement Parts

Chain Type

Left-hand Cutter

Right-hand Cutter

Tie Strap

Preset Tie Strap

Drive Link

72LGX/JGX

P26197 (25-PK.)

P26198 (25-PK.)

P23837 (25-PK.)

P23910 (25-PK.)

P65715 (25-PK.)

73LGX/JGX

P26197 (25-PK.)

P26198 (25-PK.)

P23837 (25-PK.)

P23910 (25-PK.)

P68183 (25-PK.)

75LGX/JGX

P26197 (25-PK.)

P26198 (25-PK.)

P23837 (25-PK.)

P23921 (25-PK.)

P30927 (25-PK.)

Maintenance Tools

File Size

Assembled File

Guide

Round Files

Depth Gauge

Tool, .025"

Flat File

Bench Grinder

Wheel 5 3/4"

Mini Grinder

Wheel, 4 1/4"

7/32" (5.6mm)

31686 (EA.)

70502 (12-PK.)

40458 (2-PK.)

31941 (10-PK.)

12211 (12-PK.)

OR534-316

(3/16" Thick)

OR4125-316

(3/16" Thick)

Which cutter sequence is best, standard or skip?

What type of cutting do you do?

The cutter sequence to use:

I cut "non-fibrous" woods of average size, with guide bars up to 24"

Standard sequence (72LGX, 73LGX, 75LGX)

I cut fibrous woods, such as cedar or hemlock

Skip sequence (72JGX, 73JGX, 75JGX)

I cut large wood using very long bars, approximately 28" or longer

Skip sequence (72JGX, 73JGX, 75JGX)

FILING

INSTRUCTIONS

(without file guide)

A

B

C

D

TOp pLaTe aNGLe

DOWN aNGLe

DepTh GaUGe SeTTING

FINISheD CUTTeR

GRINDING

INSTRUCTIONS

VISe ROTaTe aNGLe

VISe TILT aNGLe

heaD TILT aNGLe

DepTh GaUGe SeTTING

FINISheD CUTTeR

25º

25º

10º

10º

55º

.025"

(.6 mm)

.025"

(.6 mm)

When using an OREGON

®

file guide, ALWAYS

hold it level, 0°, flat on the Top Plate.

*

.025"

(.6 mm)

.025"

(.6 mm)

.025"

(.6 mm)

.025"

(.6 mm)

*

(LGX not available in Multicut)