91vg f&b 8-21 pg2.pdf, Hand filing instructions oregon 91vg, Grinding instructions oregon ® 91vg – Oregon 91VG User Manual

Page 2: Chain replacement parts, Maintenance tools

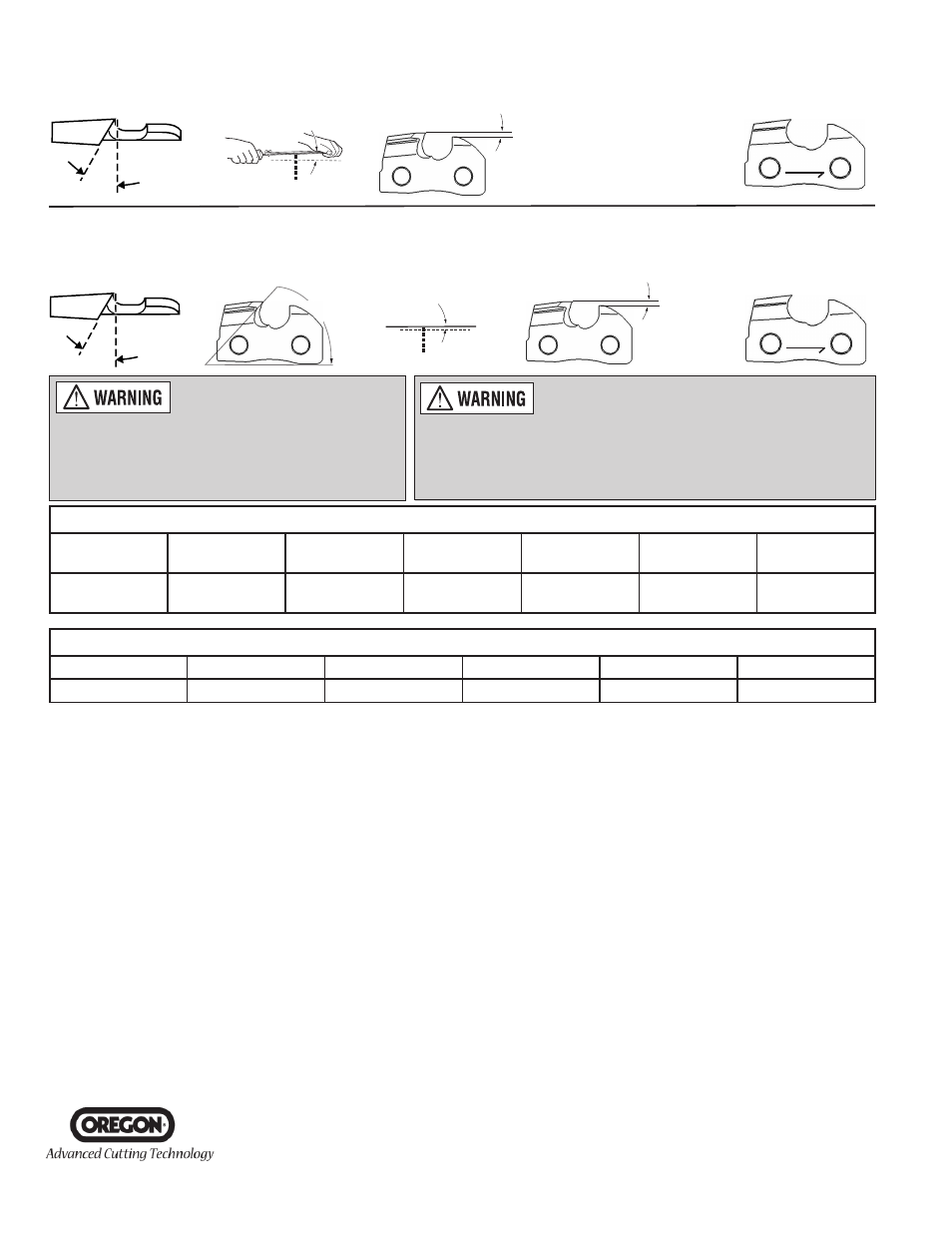

TOP-PLATE FILE HANDLE DEPTH-GAUGE SETTING:

FINISHED

FILING ANGLE: DOWN ANGLE:

*

See warning below

CUTTER:

30˚

For more information on these and other Oregon® products, contact your authorized Oregon® distributor, or:

OREGON CUTTING SYSTEMS DIVISION, BLOUNT, INC.

PO Box 22127 · Portland, OR, U.S.A. 97269-2127

Phone: 503-653-8881 Fax: 503-653-4201 Web: http://www.oregonchain.com

IN CANADA: OREGON DISTRIBUTION LTD.

505 Edinburgh Rd. N., Guelph, Ontario, Canada N1H 6L4

Phone: 519-822-6870 Fax: 519-822-4999 Printed in USA 91VG F&B A107041 AA 0806

*

*

Hand Filing Instructions OREGON 91VG

®

TOP-PLATE TOP-PLATE DEPTH-GAUGE SETTING:

FINISHED

GRINDING ANGLE: SHARPNESS ANGLE: DOWN ANGLE: *See warning below

CUTTER:

30˚

FILE SIZE: Use a 5/32” round file and file guide

Grinding Instructions OREGON ® 91VG

NOTE: Individual parts packages contain 25 pieces.

Chain Replacement Parts

Chain Type

Left-hand Cutter

Right-hand Cutter Tie Strap

Preset Tie Strap

Drive Link

91VG

P21693

P21694

P24295

P25068

P21721

Maintenance Tools

File Size

Assembled File

Guide

Round Files

Depth Gauge

Tool, .025”

Flat File

Bench Grinder

Wheel 5 3/4”

Mini Grinder

Wheel, 4 1/8”

5/32”

37534 (EA.)

70504 (12-PK.)

40458 (2-PK.)

22290 (10-PK.)

12211 (12-PK.)

OR534-18

OR4125-18

GRINDING WHEEL THICKNESS: 1/8”

these

Oregon® 91VG saw chain is low-kickback saw chain. It met the

kickback performance requirements of ANSI B175.1 (US) and

CSA Z62.3 (Canada) when tested on a representative sample of chainsaws. Its safety features

significantly reduce the hazard of kickback while maintaining high-cutting performance.

ALL CUTTING SAW CHAIN CAN KICKBACK, which may result in severe injury to the saw

operator or bystanders. Operate your saw safely. Read and follow all warnings

in your chainsaw operator’s manual.

Failure to follow filing instructions can increase

the level of kickback which can result in severe

injury to the saw operator or bystanders.

Do not exceed the depth-gauge setting shown above

Always file depth gauges back to their original rounded or ramp

shape after lowering

.0˚

.0˚

.025”

.025”

50˚