3 installation, 1 general piping – Omega FTB500 User Manual

Page 6

- 4 -

3 Installation

Upon receipt of the flowmeter carefully inspected it, checking for

any indications of damage which may have occurred during

shipment. Inspect all packing material carefully for parts or

components which may have been packed with the shipment.

Refer to the packing list/invoice for a detailed list of items

included in the shipment.

3.1

General Piping

The Omega FTB500 Series of Low Flowrate Meters is capable of

sensing fluid flow in one direction only. The meter housing is

marked by a flow direction arrow to indicate the direction of flow

through the meter. The meter must be installed in the piping in the

correct orientation to ensure the most accurate and reliable

operation. Care should be taken in the proper selection of the

mating fittings. Size, type of material, and pressure rating should

be the same as the flowmeter supplied.

When it is expected that flow will be intermittent, the meter should

not be mounted at a low point in the piping system. Solids which

settle or congeal in the meter may affect meter performance.

In order to achieve optimum electrical signal output from the

flowmeter, due consideration must be given to its isolation from

ambient electrical interference such as nearby motors, trans-

formers, and solenoids.

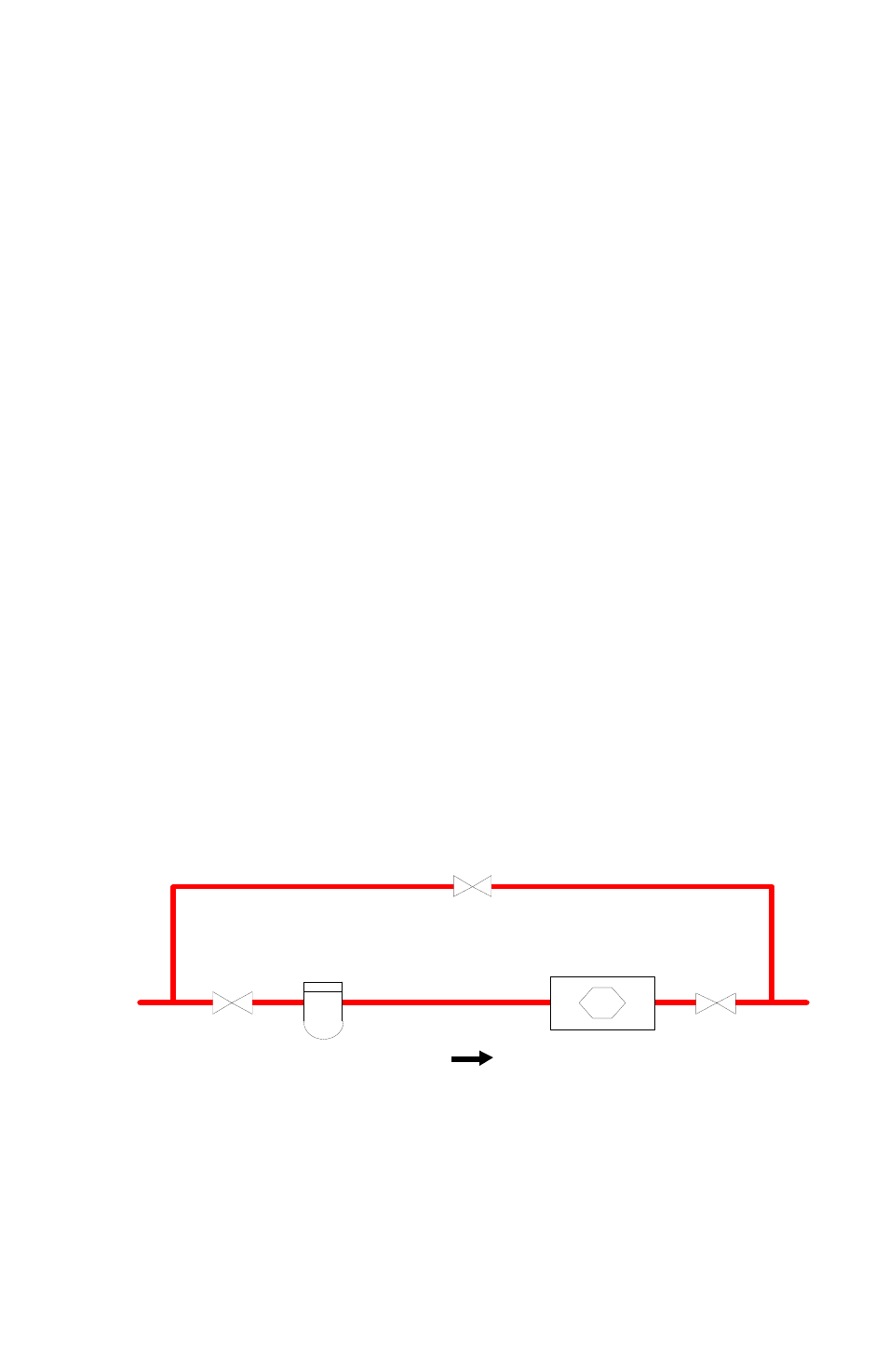

A typical flowmeter installation is shown below:

Blocking and Bypass valves should be installed if it is necessary to

do preventive maintenance on the flowmeter without shutting

down the flow system. The Bypass valve can be opened before the

Blocking valves are closed allowing the flow to continue while

removing the turbine flowmeter for service.

BYPASS RUN

Blocking Valve

Bypass Valve

Blocking Valve

Turbine Flowmeter

METER RUN

Strainer