Inspection and maintenance – Ohlins 07235-01A5L.p65 User Manual

Page 9

9

Inspection and maintenance

Clean the shock absorbers externally with a soft

detergent . Use compressed air . Be careful that

all dirt and debris is removed.

Lift the bump rubber and clean the area below

(Fig.16).

Keep the shock absorbers clean and always

spray them with oil (QS 14, WD40 or CRC 5-56

or similar) after washing the vehicle.

CAUTION!

Never use detergents that can damage the sur-

faces of the shock absorber. Use of thinner and

brake cleaner will dry the surfaces too much..

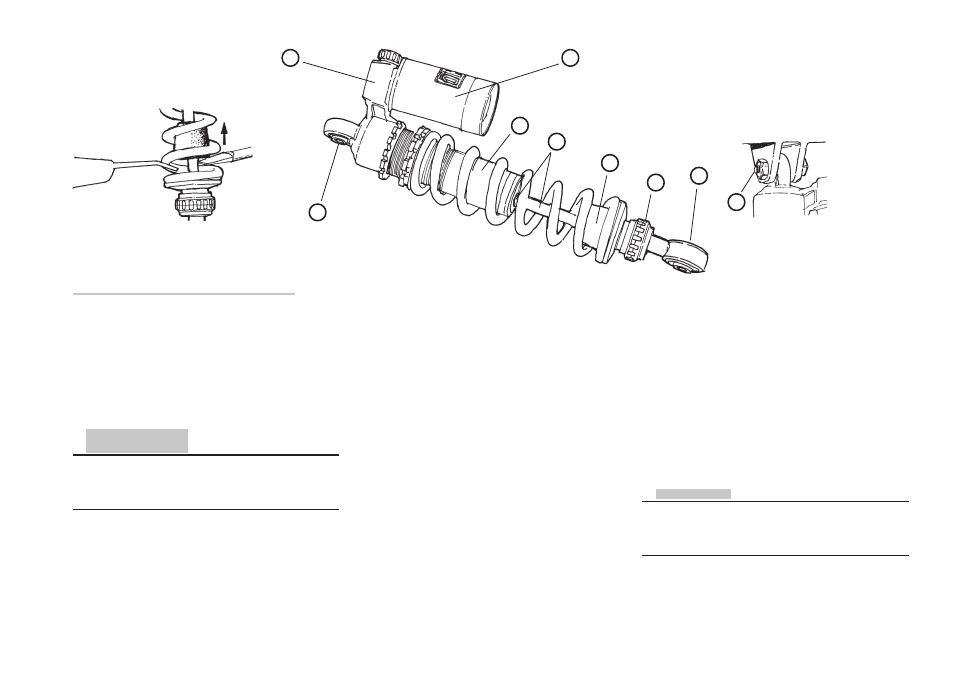

Inspection points: (Fig.17)

1. Check ball joints for possible excessive play.

2. Check the piston shaft for leakage and damage.

3. Check the shock absorber body and for

external damages.

4. Check the external reservoir for damages that

can restrict the floating piston from moving freely.

5. Excessive wear of rubber components

6. Fastening to the vehicle

Preventive maintenance and regular inspection

reduces the risk of functional disturbance. If there

is any need for additional service, please get in

touch with an authorised Öhlins service workshop.

There they have the necessary tools and know-

how for whatever you need.

Recommended inspection and

maintenance intervals:

Normal use

2 - 3 times a year

Race track

Every ten hours

Once a year, general:

Change shock absorber oil.

Use Öhlins shock absorber oil only.

1

1

3

4

3

2

5

5

6

16. Lift the bump rubber

and clean the area below.

17. Inspection points:

NOTE!

Make certain that your shock absorber are always

filled with Öhlins High performance shock ab-

sorber oil