Gas valve removal, Main burner & orifice removal, Igniter removal & cleaning (electronic) – Raypak 130A User Manual

Page 24: Ignition control fault codes

24

Gas Valve Removal

1. Remove burner tray from heater as described in

the Burner Tray Removal section.

2. Disconnect pilot tubing (if removing a Millivolt

valve).

3. Disconnect wires to gas valve.

4. Unscrew gas valve from manifold.

5. Reverse above procedure to reinstall.

Main Burner & Orifice Removal

1. Remove burner tray.

2. Remove screws from rear burner hold-down

bracket.

3. Lift burners from slotted spacers and slide from ori-

fices. Clean with a wire brush.

4. Orifices usually do not need to be replaced. To

clean, run either copper wire or wood toothpick

through orifice. Do not enlarge hole. To remove ori-

fice, use a socket wrench and remove from

manifold. Do not over-tighten when reinstalling.

5. Reverse above procedure to reinstall.

NOTE: If the heat exchanger is sooted badly, the

burner hold-down bracket and spacer can become

distorted from direct-flame impingement and this

usually necessitates replacement of these parts.

ORIFICES MUST BE PARALLEL WITH BASE

TOLERANCE OF +2° -0°

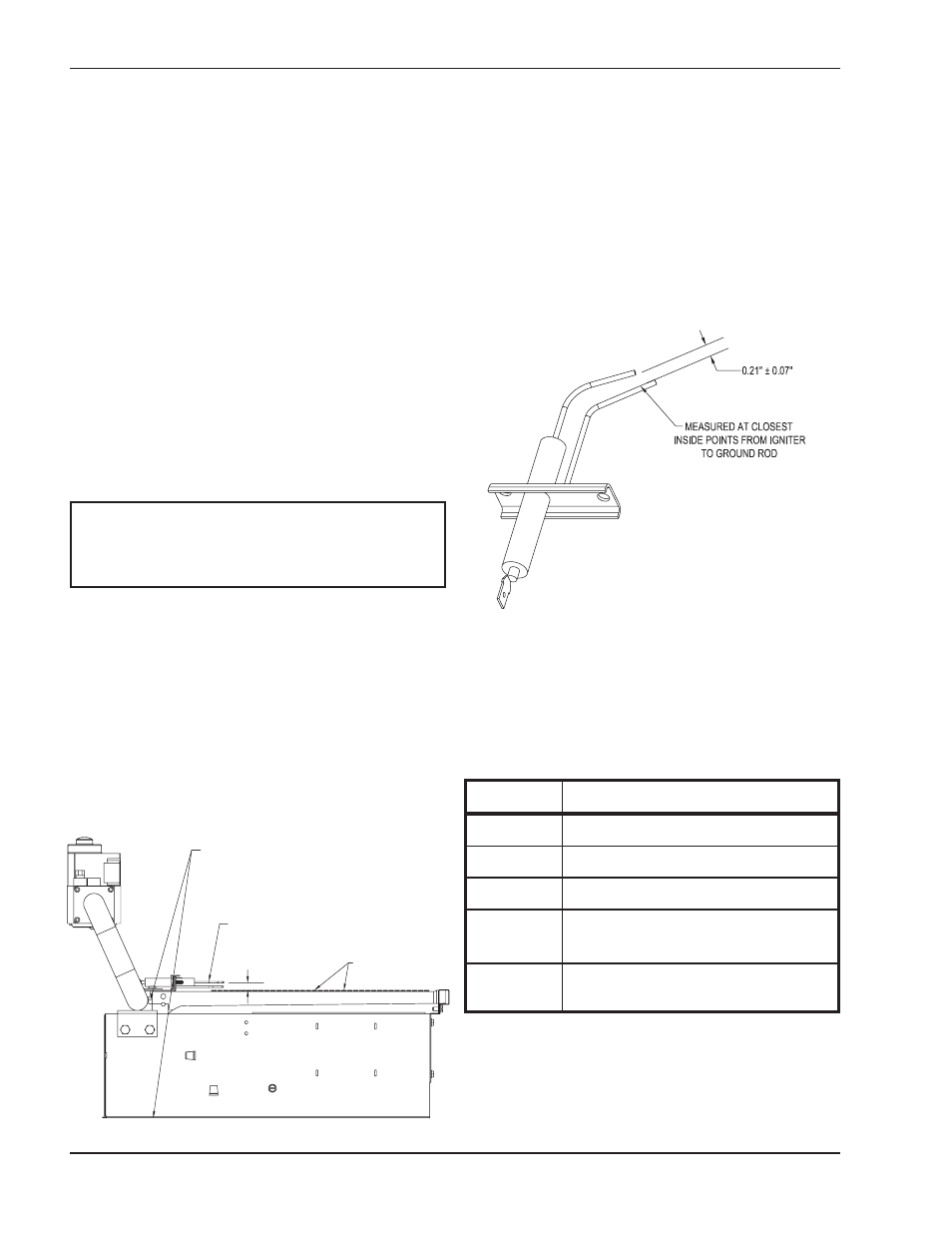

IGNITER

BETWEEN IGNTER & BURNER

PORTS 0.375” ± 0.125”

BURNER PORTS

Fig. 31: Igniter Position to Burners

Igniter Removal & Cleaning

(Electronic)

1. Disconnect high tension wire from igniter.

2. Remove (2) screws that mount the igniter to the

burner tray.

3. Remove igniter from burner tray.

4. Reverse above procedure to reinstall.

Ignition Control Fault Codes

The ignition control fault codes listed in Table H can be

used to troubleshoot ignition problems.

Fig. 32: Direct Spark Igniter

Code

Condition

Steady On

Power applied, control OK

Steady Off

No power or control hardware fault

1 Flash

Ignition lockout from too many trials

2 Flashes

Ignition lockout from too many flame

losses in single call for heat

3 Flashes

Control hardware/software fault

detected

Table H: Ignition Control Fault Codes