Features, Chip shield, Spindle lock – Ryobi RE170VS User Manual

Page 7: Ergonomic handles, Electronic variable speed control, Soft start, Variable speed, Electronic feedback, Applications, Upside down view of router

Page 7

3/8

15

64

1 64

0

1

32

3

7

32

64

8

1

7

64

3

3

9 64

5 32

11

64

6

13

6

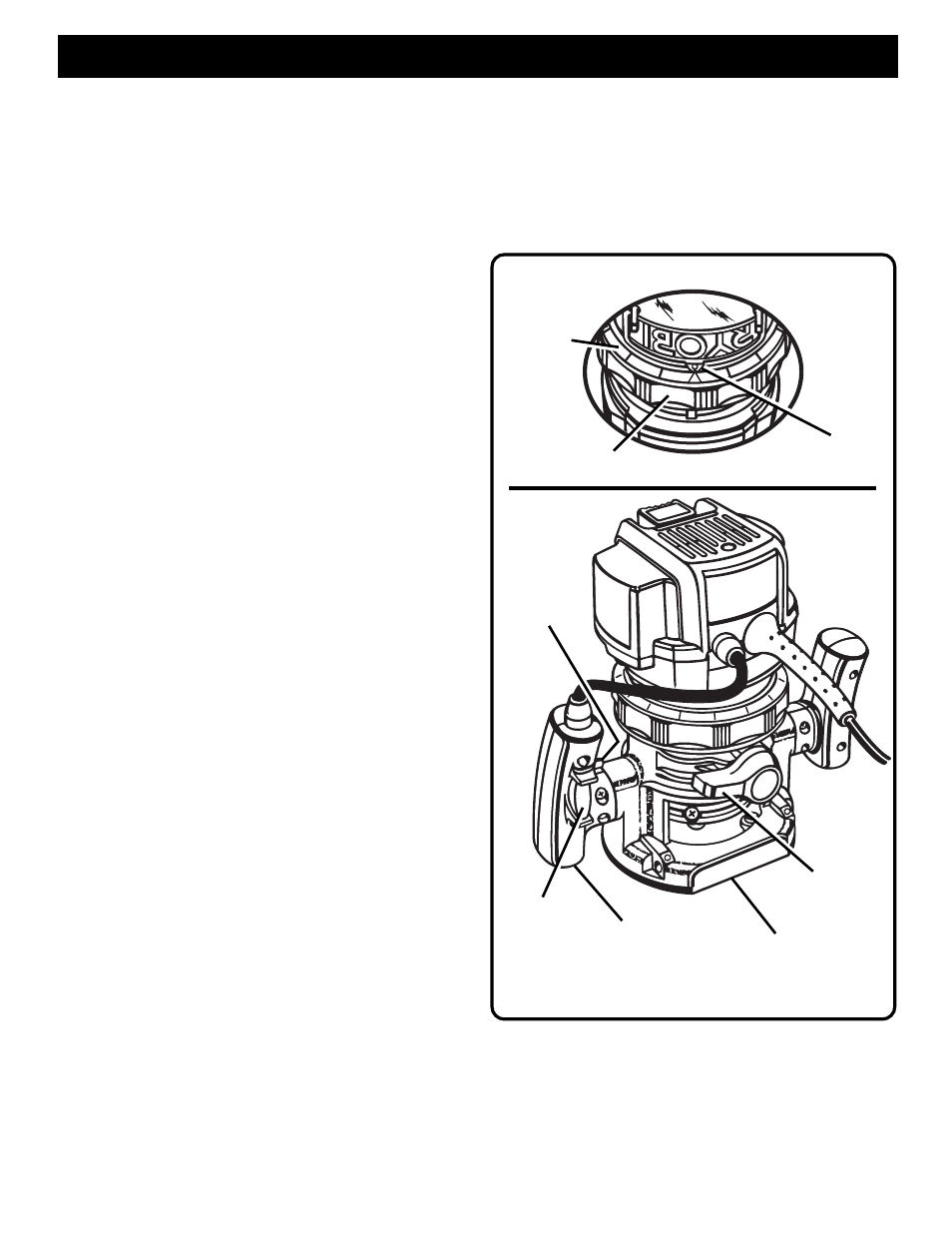

FEATURES

CHIP SHIELD

A clear plastic see-through chip shield is installed on the front

of your router for protection against flying dust and chips.

The shield is designed to fit the front opening of the router

base.

See Figure 1. If necessary to remove chip shield,

squeeze the tabs on each end and pull outward. To replace,

squeeze the tabs at each end, fit into opening, then release.

FOR YOUR PROTECTION, DO NOT USE ROUTER

WITHOUT CHIP SHIELD PROPERLY IN PLACE.

SPINDLE LOCK

A spindle lock secures the spindle so that only one wrench

is needed to loosen the collet nut and change cutters. It also

leaves both hands free for changing cutters.

NOTE: Your router will not run if spindle is locked.

ERGONOMIC HANDLES

The handles on your router provide for easy handling and

maintaining proper control when routing.

The handles have also been designed so that they are

comfortable and easy to grasp when operating in different

positions.

ELECTRONIC VARIABLE SPEED CONTROL

Your router has advanced electronic features, designed to

assist you in getting the maximum use from your router. By

making proper speed selections, your router can be adjusted

to specific routing needs. This eliminates much of the guess

work previously needed to perform a given job. Both the

experienced and inexperienced router users benefit, obtaining

professional like results with fewer job errors.

SOFT START

The soft start feature builds motor RPM gradually to minimize

start-up torque.

VARIABLE SPEED

The variable speed control feature allows the router to

develop a no load speed that can be adjusted from 15,000 to

25,000 RPM. The variable speed control selector is

conveniently located under the end cap on the side of your

router.

Speed can be set according to the approximate cutter

diameter you will be using and to the hardness of the material

being cut. See the chart in figure 10, on page 11. The best

cuts are made when the cutter is fed through material at the

proper rate of feed.

ELECTRONIC FEEDBACK

The electronic feedback feature of your router introduces the

flexibility of adjusting the motor speed to required job

conditions. An electronic speed control module senses the

load applied to the motor, and increases or decreases motor

voltage to compensate for and maintain desired RPM.

SWITCH

TRIGGER

LOCK-ON

BUTTON

DEPTH

INDICATOR

RING(S)

APPLICATIONS

(Use only for the purposes listed below)

■

Routing grooves, shaping edges, freehand designs, etc.

in wood.

■

Chamfering, rabbeting, dadoing, and dovetailing in wood.

■

Routing edges on laminates.

CLAMPING

LEVER

SUBBASE WITH

STRAIGHT EDGE

Fig. 2

POWER

HANDLE

UPSIDE DOWN VIEW OF ROUTER

INDICATOR

POINT(S)

DEPTH

ADJUSTING RING

REAR VIEW OF ROUTER