Maintenance – Ryobi P542 User Manual

Page 21

21 - English

Replace the chain cover, washer and chain

cover screw. Tighten the chain cover screw

finger tight only. The bar must be free to move

for tension adjustment.

Remove all the slack from the chain by turning

the chain tensioning screw clockwise until the

chain seats snugly against the bar with the drive

links in the bar groove.

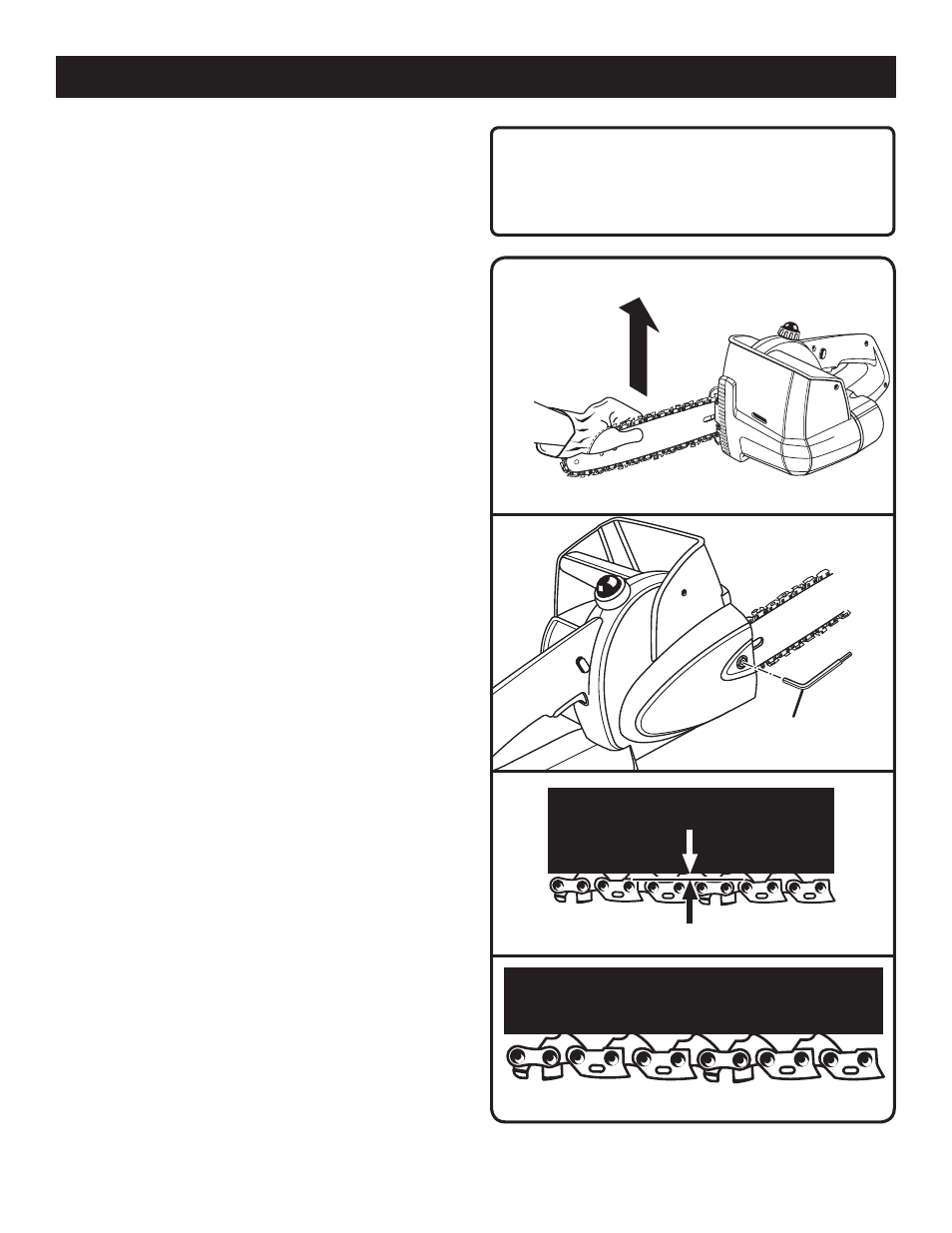

Lift the tip of the guide bar up to check for

sag. Release the tip of the guide bar and turn

the chain tensioning screw 1/2 turn clockwise.

Repeat this process until sag does not exist.

Hold the tip of the guide bar up and tighten the

bar mounting screw securely.

Chain is correctly tensioned when there is no

sag on the underside of the guide bar, the chain

is snug, but it can be turned by hand without

binding.

NOTE: If chain is too tight, it will not rotate.

Loosen the chain cover screw slightly and turn

tension adjuster 1/4 turn counterclockwise. Lift

the tip of the guide bar up and retighten chain

cover screw securely. Assure that the chain will

rotate without binding.

Place the hex key back into the storage area.

cHAIN TENSION

See Figures 28 - 29.

Stop the engine before setting the chain tension.

Make sure the guide bar screw is loosened to

finger tight, turn the chain tensioner clockwise

to tension the chain. Refer to

Replacing Bar

and chain earlier in this manual for additional

information.

A cold chain is correctly tensioned when there

is no slack on the underside of the guide bar,

the chain is snug, but it can be turned by hand

without binding.

Chain must be re-tensioned whenever the flats

on the drive links hang out of the bar groove.

During normal saw operation, the temperature

of the chain will increase. The drive links of

a correctly tensioned warm chain will hang

approximately .050 in. out of the bar groove.

NOTE: New chain tends to stretch, check chain

tension frequently and tension as required.

MAINTENANcE

cAUTION:

Chain tensioned while warm, may be too tight

upon cooling. Check the “cold tension” before

next use.

Fig. 26

Fig. 27

HEX KEY

LIFT THE TIP OF

THE GUIDE BAR

UP TO CHECK FOR

SAG

APPROX. .050 in.

Fig. 29

FLATS

Fig. 28