Operation – RIDGID R2600 User Manual

Page 11

11

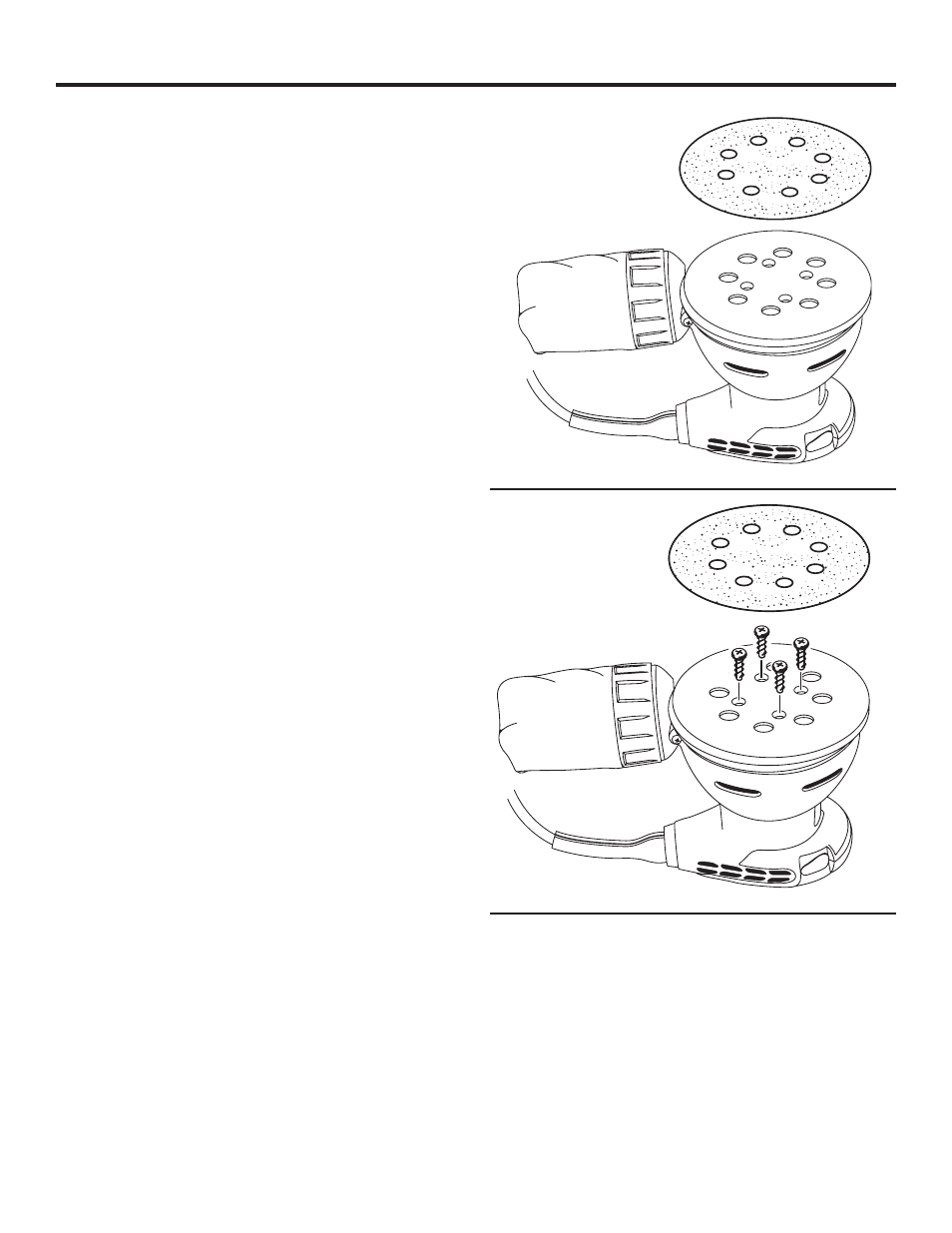

ATTACHING HOOK AND LOOP SANDING

DISCS

See Figure 2.

n

Unplug the sander.

n

. Align holes in hook and loop type sanding disc with

holes in pad, then carefully press fuzzy side of sanding

disc against pad as tightly as possible.

NOTE: Hook and loop type sanding discs can be

reused for the life of the sanding abrasive. It is recom-

mended that you keep the sanding disc backing pad

clean to provide for best adhesion. Clean occasionally

by brushing lightly with a small brush.

REPLACING THE PRESSURE SENSITIVE

ADHESIVE (PSA) SANDING PAD AND DISC

ATTACHMENT

See Figure 3.

The sander comes assembled with the Micro-Fiber™

hook and loop pad. To attach the pressure sensitive adhe-

sive (PSA) pad, you must first remove the hook and loop

pad.

Inspect sanding disc before installing. Do not use if bro-

ken or defective.

n

Unplug the sander.

n

Remove the four screws that hold the hook and loop

pad in place.

n

Remove the hook and loop pad.

n

Clean dust particles from the pad brake.

n

Apply a thin layer of lightweight grease to the back of

the pad.

n

Align the holes in the pressure sensitive adhesive (PSA)

pad with the four screw holes in the sander.

n

Replace the four screws securely.

n

Carefully peel paper backing from the pressure sen-

sitive adhesive type sanding disc.

n

Align holes in sanding disc with holes in backing pad,

then carefully press sticky side of disc against pad as

tightly as possible.

NOTE: Holes in sanding disc must line up with holes in

the backing pad in order for the dustless feature of the

sander to function properly.

NOTE: It is recommended that you clean backing pad

occasionally by brushing lightly with a small brush.

Dust buildup on backing pad could cause sanding disc

not to stick properly.

REMOVE PSA SANDING DISC BEFORE

STORAGE

Do not store the sander with the sanding disc installed.

Heat generated from sanding causes the pressure sen-

sitive adhesive to flow and form a tight bond between the

backing pad and sanding disc.

OPERATION

Fig. 2

Fig. 3

Removing the sanding disc soon after you have finished a

sanding operation avoids letting the adhesive set up. If the

sanding disc is left on the backing pad for an extended

period of time after use, the adhesive will set up and

cause the sanding disc to become difficult to remove.

It may also tear when removing. When this situation oc-

curs, it becomes difficult to clean the backing pad for the

next sanding disc.

NOTE: If you forget to remove the sanding disc after a

sanding operation, sand for a few minutes to soften the

adhesive backing before attempting to remove sanding

disc.