Maintenance and repair instructions (continued) – Ryobi 990r User Manual

Page 24

24

MAINTENANCE AND REPAIR INSTRUCTIONS (Continued)

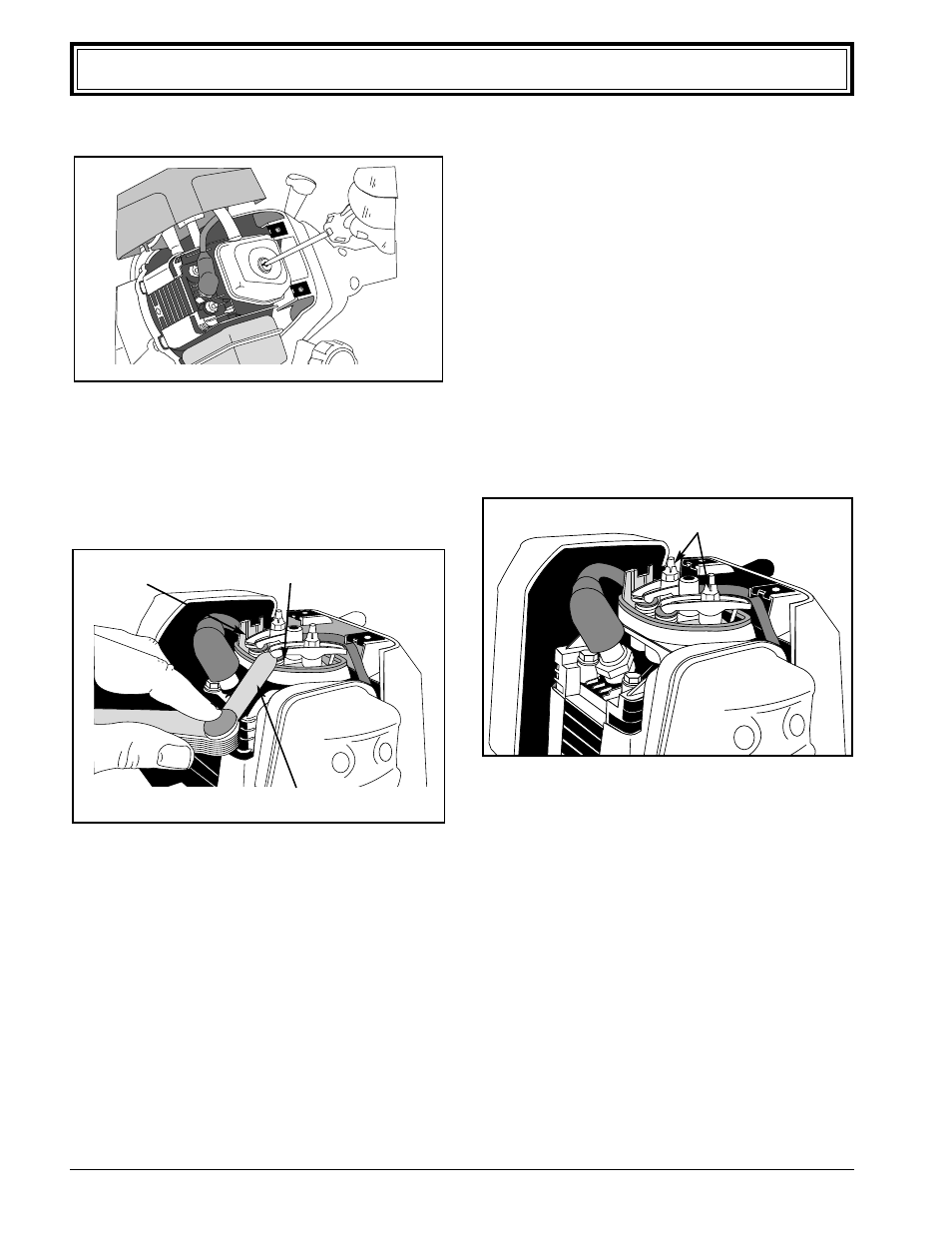

3. Remove the rocker arm cover and gasket, using a T-

25 Torx® screwdriver (Fig. 50).

Fig. 50

Flat Feeler Gauge

Valve

Rocker Arm

Fig. 51

4. Position the crankshaft so the piston is at the top of

the compression stroke (the rocker arms are free and

loose).

5. Measure the clearance between the valve stems and

rocker arms, using a flat feeler gauge (Fig. 51).

The recommended valve to rocker arm clearance for both

the intake and exhaust is 003-.006 in. (.076 mm-.152

mm).

6. If the clearance is not within specification, adjust as

follows:

a.

Turn the adjusting nut (Fig. 52), using an 5/16 in

(8 mm) wrench or nut driver.

To increase the rocker arm to valve clearance,

turn the adjusting nut counterclockwise.

To decrease the rocker arm to valve clearance,

turn the adjusting nut clockwise.

b.

Recheck the clearance with a flat feeler gauge

and readjust as necessary (Fig. 49).

7. Reinstall the rocker arm cover using a new gasket.

Torque the rocker arm cover screw to 20-30 in•lb

(2.2-3.4 N•m)

(Fig. 50).

Fig. 52

Adjusting Nuts

8. Reinstall the engine cover and screws (see Figs. 48

and 49 on page 22).

Torque the top screws to 10-12 in•lb (1.1-1.3 N•m).

Torque the front screw to 10-15 in•lb (1.1-1.7 N•m).

Torque the rear screw with washer to 25-30 in•lb

(2.8-3.4 N•m).